High-speed railway noise reduction structure

A high-speed railway, noise reduction technology, applied in the direction of noise absorption devices, bridge parts, bridges, etc., can solve the problems of heavy maintenance workload, high maintenance cost, passenger line of sight blocking, etc., to achieve small maintenance workload and consistent service life , the effect of good landscape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

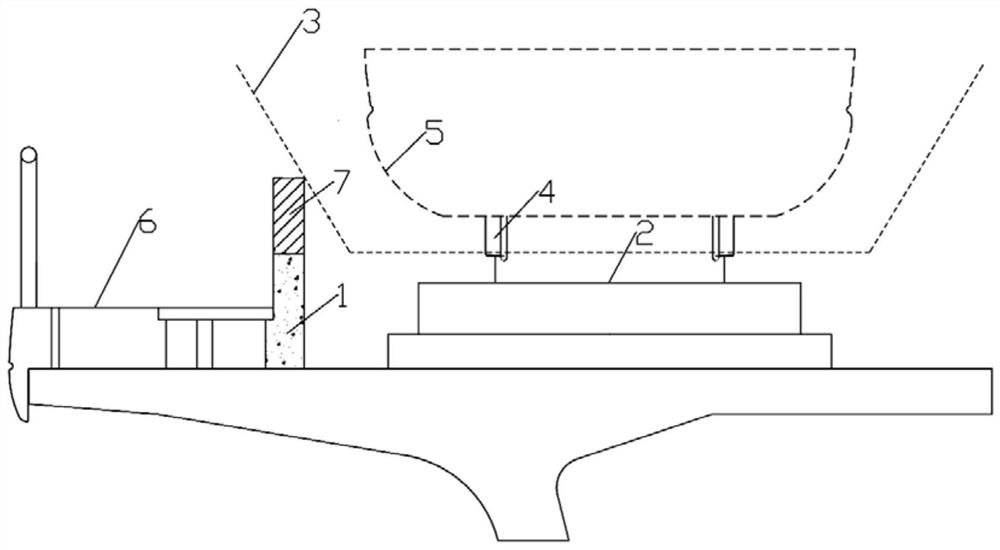

[0031] Such as figure 1 As shown, a high-speed railway noise reduction structure 7 extends along the outer side of the high-speed railway track for reducing noise outside the vehicle. The noise reduction structure is installed on the protective wall 1, and the inner side of the noise reduction structure is 200cm away from the center of the track.

[0032] In detail, the noise reduction structure 7 has a rectangular section in the vertical direction, which is formed by extending upward from the top of the protective wall. The height of the rectangular section is 50 cm, and the width is 20 cm. The inner top of the rectangular section is close to the railway building limit 3 .

Embodiment 2

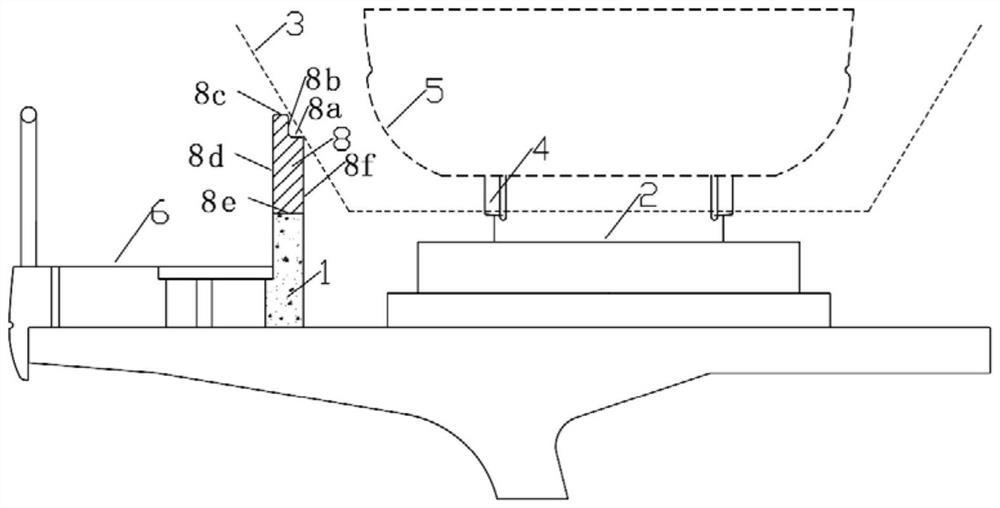

[0034] Such as figure 2 As shown, a high-speed railway noise reduction structure extends along the outer side of the high-speed railway track to reduce the noise outside the vehicle. The noise reduction structure is installed above the protective wall 1, and the inside of the bottom of the noise reduction structure is 200cm away from the center of the track.

[0035] In detail, the cross-sectional shape of the noise reduction structure in the vertical direction is stepped, surrounded by a stepped top surface, an inner surface 8f, an outer surface 8d and a bottom surface 8e, and the stepped top surface One side sinks to form, the inner surface 8f is flush with the inside of the protective wall, and the outer surface 8d is flush with the outer side of the protective wall; the bottom surface 8e is located at the top of the protective wall; the width of the first horizontal section 8a of the stepped top surface is 10cm, The width of the second horizontal section 8c is 10cm, and ...

Embodiment 3

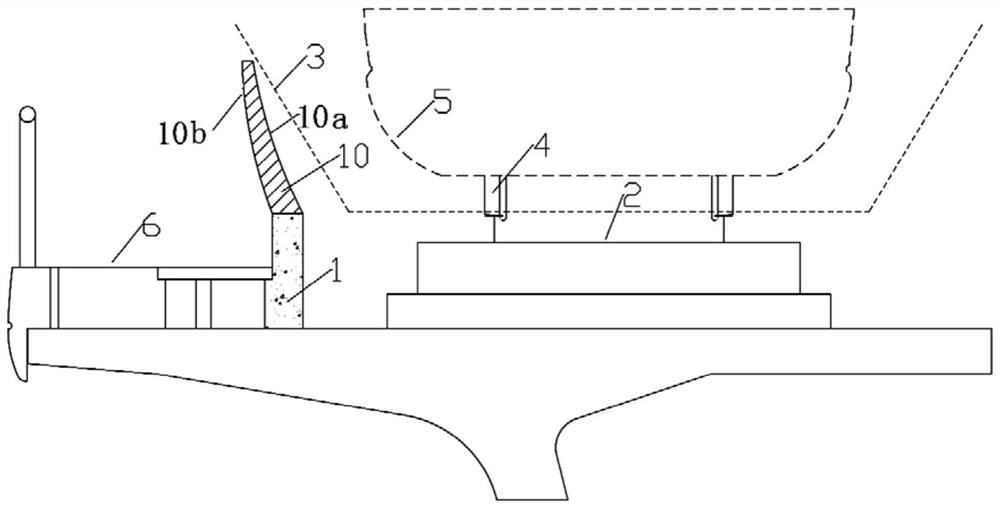

[0037] Such as image 3 As shown, a high-speed railway noise reduction structure extends along the high-speed railway track to reduce the noise outside the vehicle. The arc-shaped structure is installed above the protective wall, and the inside of the bottom of the noise reduction structure is 200cm away from the center of the track.

[0038] In detail, the noise reduction structure has an arc-shaped cross section in the vertical direction, and is composed of an arc-shaped inner surface 10a, an arc-shaped outer surface 10b, a top surface, and a bottom surface, and the arc-shaped inner and outer surfaces are at the same height. The bottom surface is installed on the protective wall, with the same width as the protective wall, which is 20cm. The width of the upper surface is 7cm. The radius of the arc-shaped inner surface 10a is 332.1 cm, and the radius of the arc-shaped outer surface 10b is 305.5 cm. The overall height of the arc-shaped structure is 100 cm, and the projected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com