High-strength coke and coking method

A high-strength, high-strength coke technology, applied in the field of coal chemical industry, can solve the problems of low coke crushing strength and low-strength CSR, and achieve the effects of easy implementation, high strength and quality maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

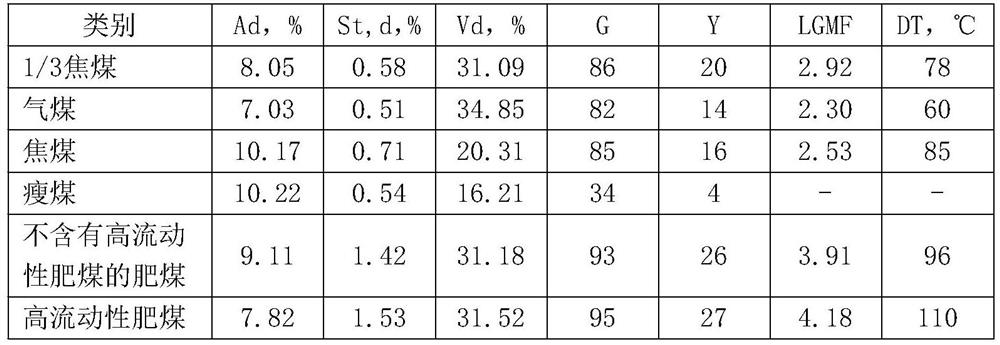

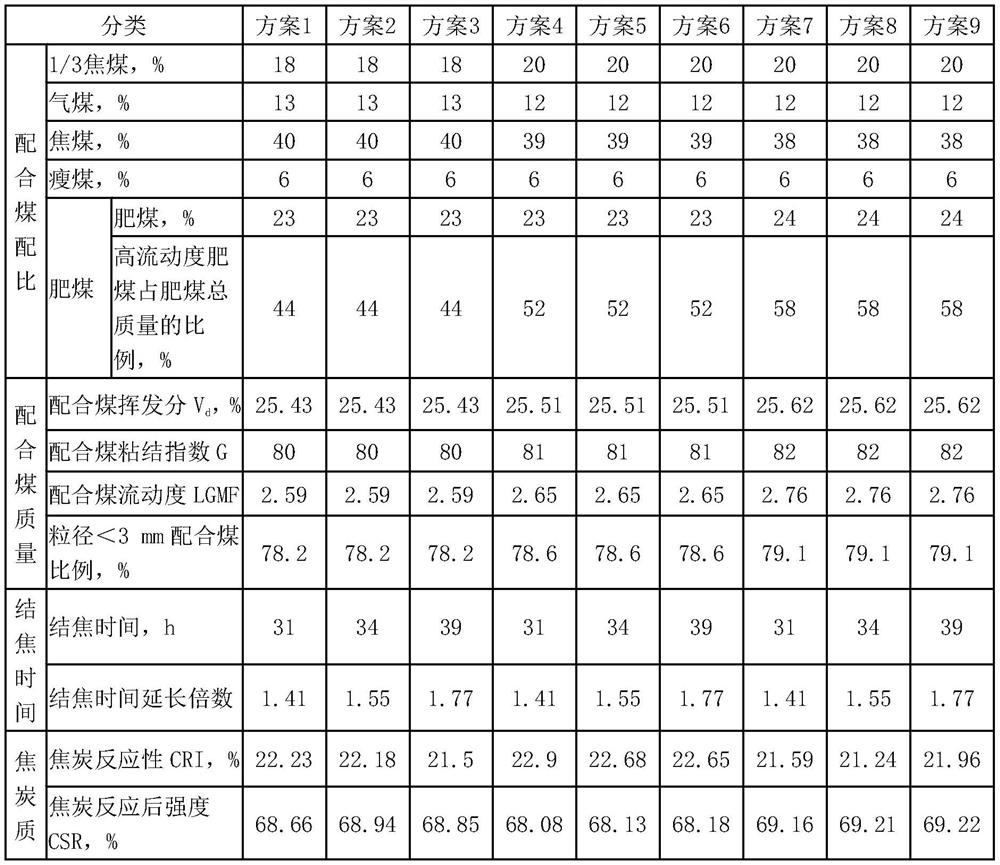

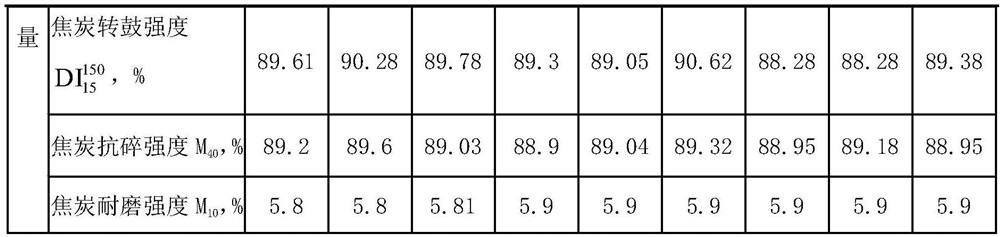

[0035] The present invention will be further described below in conjunction with the examples, as shown in Table 1-Table 2.

[0036]A kind of high-strength coke, which is produced by coking by blending coal with the following mass percentages: 1 / 3 coking coal 15-20%, gas coal 12-17%, coking coal 36-42%, lean coal 4-7%, fat coal 22- 28%, high fluidity fat coal accounts for 40-60% of the total mass of fat coal, and the sum of the mass percentages of each component of blended coal is 100%.

[0037] The volatile matter V of the high fluidity fat coal of the embodiment of the present invention d The colloid layer thickness Y is 27mm, the fluidity LGMF is 4.18, and the softening temperature range is 110°C; the performance parameters of the coking coal used in the examples are shown in Table 1.

[0038] In the embodiment of the present invention, coking is carried out in a 7m top-loaded coal coke oven, and the coking time of the 7m coke oven is designed to be 22 hours; three proport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com