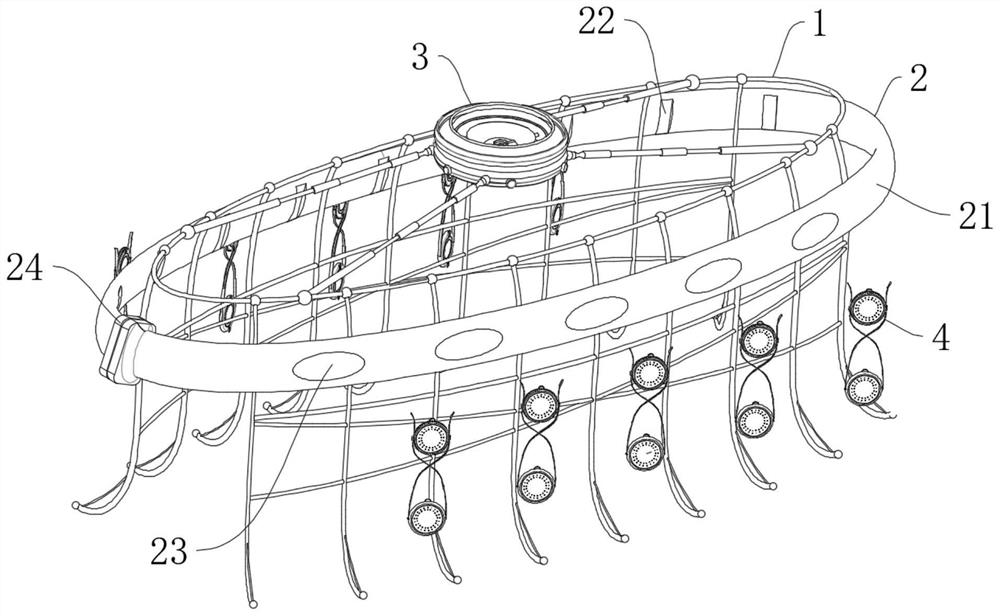

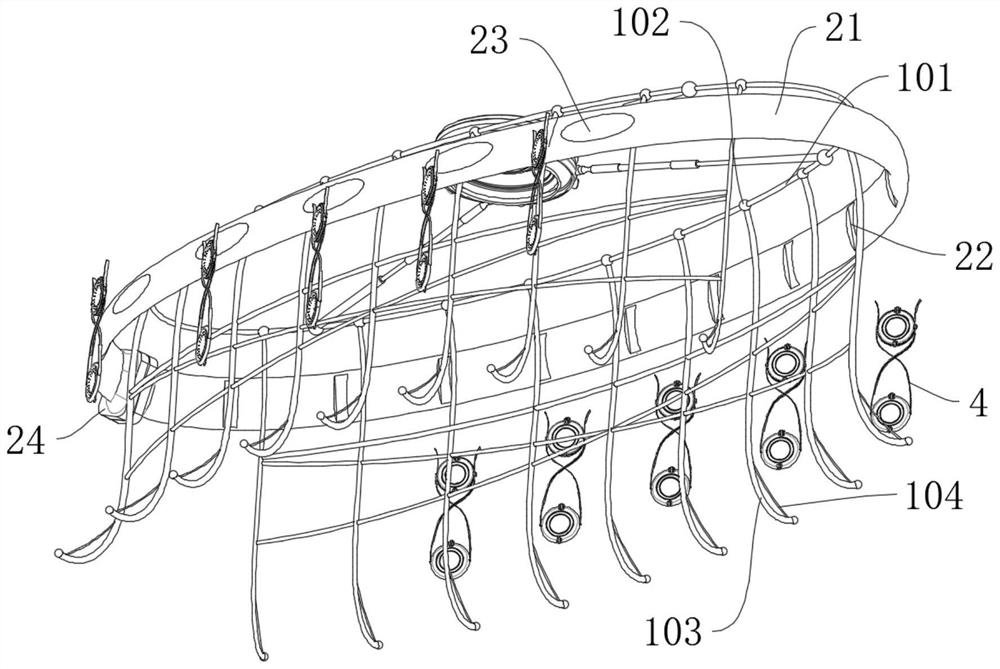

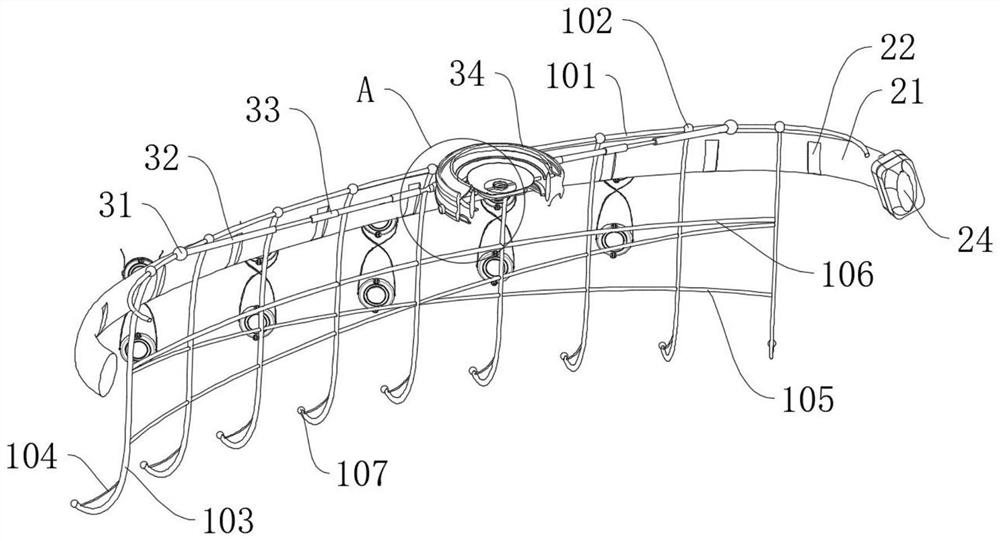

Artificial mitral valve suture-free automatic implantation device

An implantation device and mitral valve technology are applied in the field of artificial mitral valve suture-free automatic implantation device, which can solve the problems of short service cycle of biological valve and no auxiliary valve replacement device, etc., and achieve convenient and convenient angles and methods. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0052] For Embodiment 5, it needs to be further explained that the adhesive type concave disc-shaped patch 49 of the first wound positioning plate 41 and the second wound positioning plate 42 is bonded to both sides of the wound, and then the sliding cord 45 Pulling with the hollow type rope 46 achieves the effect of shrinking the distance between the first wound positioning plate 41 and the second wound positioning plate 42, and its movement characteristics are consistent with the use principle of the cable tie. The state of intersecting with the hollow type rope 46 is maintained. Under normal conditions, the first wound positioning plate 41 and the second wound positioning plate 42 are fixed on the outer wall of the support cantilever 103 for debridement through the supporting positioning bracket 48 .

Embodiment 6

[0053] Embodiment 6, the present embodiment is based on the lifting scheme of embodiment 5, wherein as Figure 8-9 , the inside of the first wound positioning disc 41 and the second wound positioning disc 42 are provided with an annular air pressure chamber 410 and a first gas storage chamber 411, the first wound positioning disc 41 and the second wound positioning disc 42 are made of rubber, ring-shaped The air pressure chamber 410 communicates with the first gas storage chamber 411, and the first gas storage chamber 411 communicates with a second gas storage chamber 412 on the side away from the adhesive-type inner concave disk-shaped patch 49, and the first wound positioning plate 41 is connected with the The second wound positioning plate 42 is provided with a gas one-way valve 413 on the side close to the second gas storage chamber 412. The gas one-way valve 413 is sealed at the gas outlet of the second gas storage chamber 412, and the adhesive type is concave. An air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com