Vacuumizing equipment for liquefied natural gas bottle for double-layer vehicle and vacuumizing method of vacuumizing equipment

A technology for liquefied natural gas and vacuum pumping equipment, which is used in liquid/vacuum degree measurement of liquid tightness, mechanical equipment, liquid variable capacity machinery, etc. , to prevent loosening and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

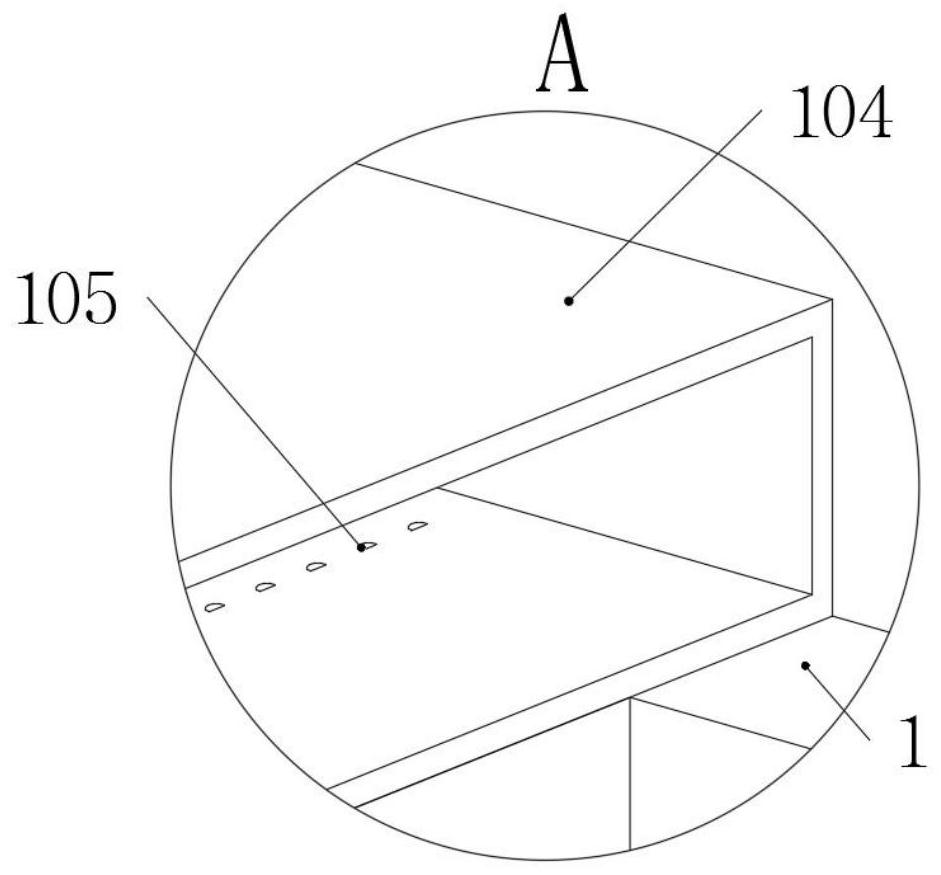

[0046] Example: Please refer to Figure 1 to Figure 9 :

[0047] The present invention proposes a vacuum pumping device and a vacuum pumping method for a double-layer liquefied natural gas bottle for vehicles, comprising: a frame body 1, a vacuum pumping part 2 and a tank body 3;

[0048] Four universal wheels are installed on the frame body 1, and all four universal wheels are in contact with the ground;

[0049] The vacuum part 2 is composed of a mounting base 201, a device main body 202, a fixing bolt 203, a connecting pipe 204, a joint 205 and a card slot 206, and the mounting base 201 is installed on the frame body 1;

[0050] The tank body 3 is composed of a valve seat 301 , a valve rod 302 and a protective cover 303 , and the valve seat 301 is installed on the tank body 3 .

[0051] Furthermore, according to an embodiment of the present invention, as figure 1 and Figure 5As shown, the mounting seat 201 is fixedly connected to the frame body 1 by four fixing bolts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com