Multi-layered vibration suppression structure with tension assembly

A technology of components and components, which is applied in the field of multi-layer vibration suppression structures, can solve the problems of structural columns affecting the architectural effect and the lower traffic requirements, the large cross-section requirements of the vertical web members of the vierendeel truss, and the inability to achieve light and thin architectural effects, etc., so as to avoid the use of TMD, simple structure, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

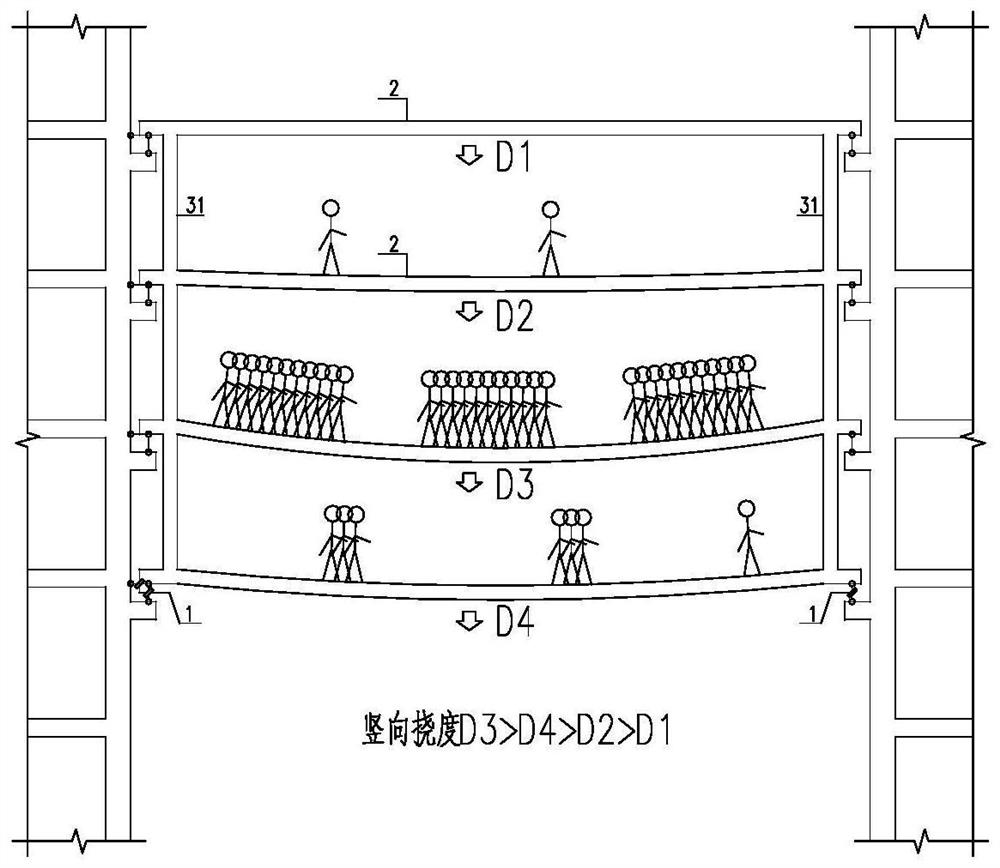

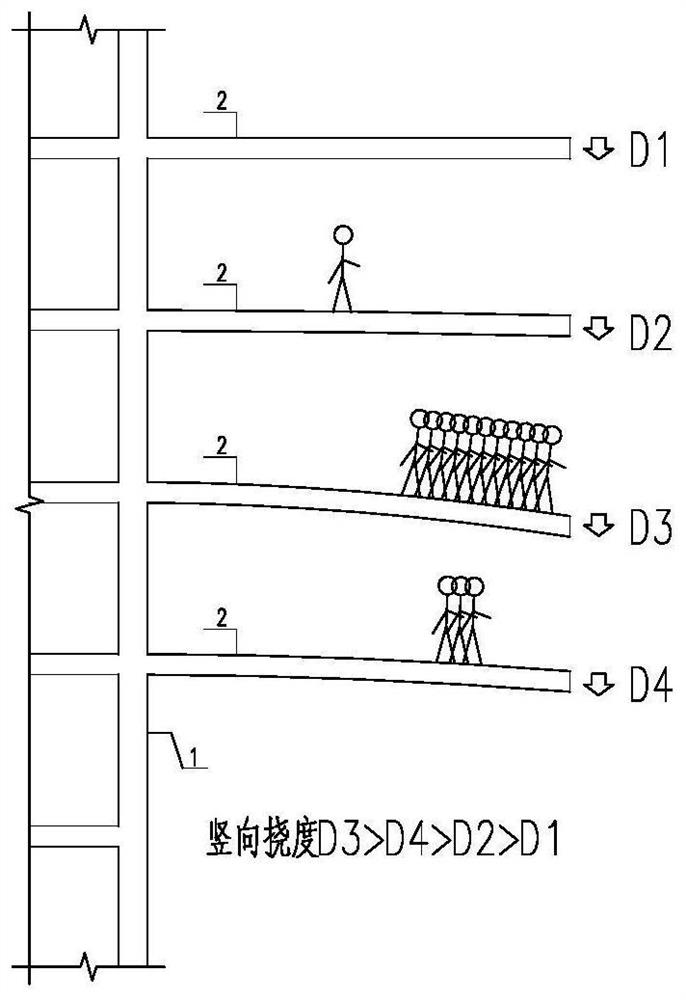

[0087] Such as image 3 As shown, the multi-layer vibration suppression structure has an upper floor component 2 , a middle and upper floor component 2 , a middle and lower floor component 2 and a lower floor component 2 . Between the upper floor member 2 and the middle and upper floor member 2, the middle and upper floor member 2 and the middle and lower floor member 2, the middle and lower floor member 2 and the lower floor member 2, the two ends of which are respectively connected by rigid joint columns 31, and the middle spans are respectively A tension member 32 is provided. The tension components 32 are arranged vertically. This embodiment is the simplest implementation form of the present invention, and has the least impact on the facade.

Embodiment 2

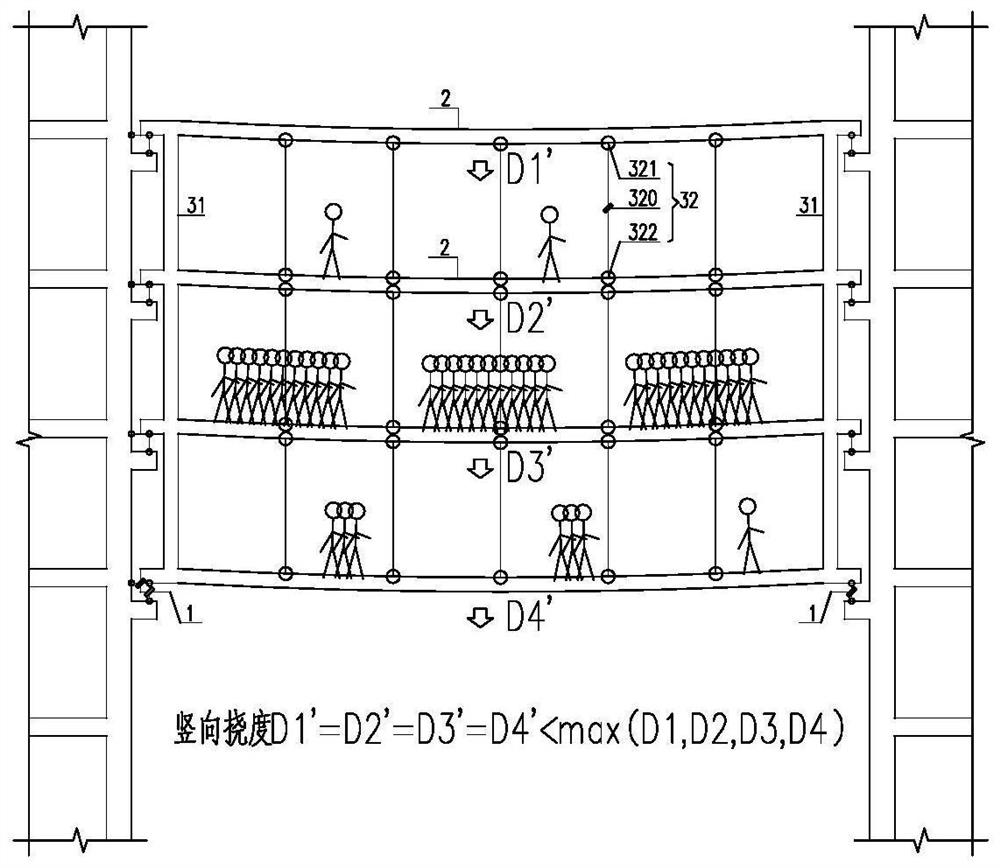

[0089] Such as Figure 4 As shown, the multi-layer vibration suppression structure has an upper floor component 2 , a middle and upper floor component 2 , a middle and lower floor component 2 and a lower floor component 2 . Between the upper floor member 2 and the middle and upper floor member 2, the middle and upper floor member 2 and the middle and lower floor member 2, the middle and lower floor member 2 and the lower floor member 2, the two ends of which are respectively connected by rigid columns 31, and the middle part is in each Several tension components 32 are arranged at equal intervals in the layers. The tension components 32 of each layer are arranged vertically, and the tension components 32 of different layers are aligned. Compared with Embodiment 1, this embodiment has a better vibration suppression effect.

Embodiment 3

[0091] Such as Figure 5 As shown, the multi-layer vibration suppression structure has an upper floor component 2 , a middle and upper floor component 2 , a middle and lower floor component 2 and a lower floor component 2 . Between the upper floor member 2 and the middle and upper floor member 2, the middle and upper floor member 2 and the middle and lower floor member 2, the middle and lower floor member 2 and the lower floor member 2, the two ends of which are respectively connected by rigid columns 31, and the middle part is in each A number of tension components 32 are arranged at unequal intervals in the layers. The tension components 32 are arranged vertically, and the tension components 32 of different layers are aligned. Compared with Embodiment 2, this embodiment can meet the requirements of specific visual effects or use functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com