Ultra-thin asphalt pavement for high-grade highway

An asphalt pavement, high-grade technology, applied in the field of ultra-thin asphalt pavement of high-grade highways, can solve the problems of bending and tensile fatigue failure of the asphalt surface layer, the bonding layer of high-grade highways cannot play a role in advancing, and the cost is high, so as to save The effect of road construction funds, elimination of early damage, and reduction of rutting diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

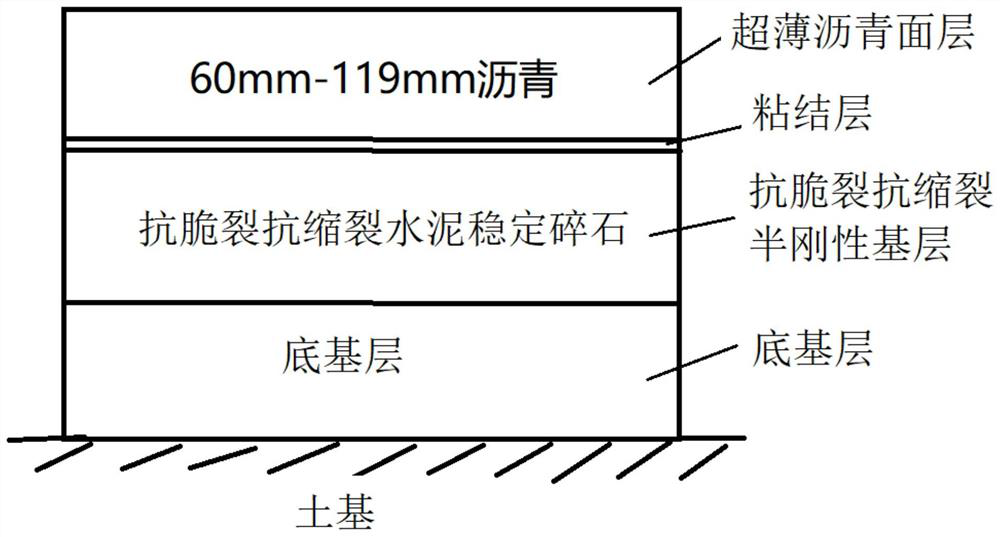

specific Embodiment 1

[0089]Xinglin Expressway K11+000—K14+000 uplink road section experimental construction, the thickness of the asphalt surface layer is 90mm; at the same time, the bonding layer is used; at the same time, the anti-brittle and anti-shrinkage semi-rigid base layer uses anti-brittle and anti-shrinkage cement to stabilize the crushed stone; At the same time, the anti-brittle and anti-shrinkage cement-stabilized crushed stone has a compacted thickness greater than or equal to 300mm; at the same time, the amount of cement is 3.0-4.0% (accounting for the total mass proportion), and the 7-day unconfined compressive strength is 2.5MPa-4.0MPa; at the same time Roll forming at a temperature of 20°C-30°C, preferably at 25°C; at the same time, the thickness of the base layer is >360mm; the mineral material gradation adopts the gradation in Table 1.

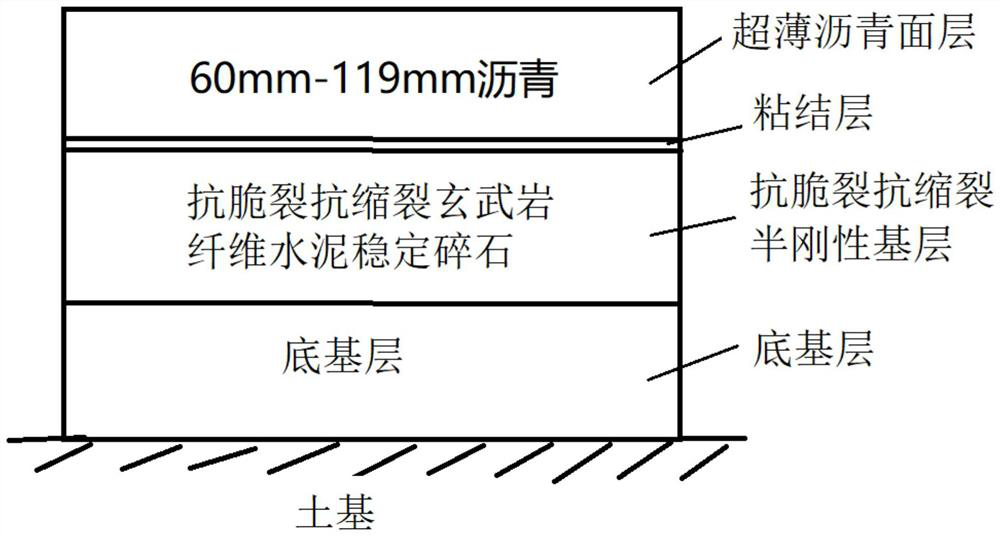

specific Embodiment 2

[0091] Experimental construction of the K11+000-k14+000 downlink section of Xinglin Expressway. The thickness of the asphalt surface layer is 90mm; at the same time, the bonding layer is used; at the same time, the anti-brittle and anti-shrinkage semi-rigid base uses the anti-brittle and anti-shrinkage basalt fiber cement to stabilize the gravel; The compacted thickness of the layer is greater than or equal to 280mm; at the same time, the amount of basalt fiber is 3.2Kg—6.0Kg / m 3 ;At the same time, the amount of cement is 3.0-4.0% (accounting for the total mass proportion), and the 7-day unconfined compressive strength is 2.5MPa-4.0MPa; at the same time, it is rolled and formed at a temperature of 20°C-30°C, preferably at 25°C. ; At the same time, the thickness of the base layer is greater than or equal to 360mm;

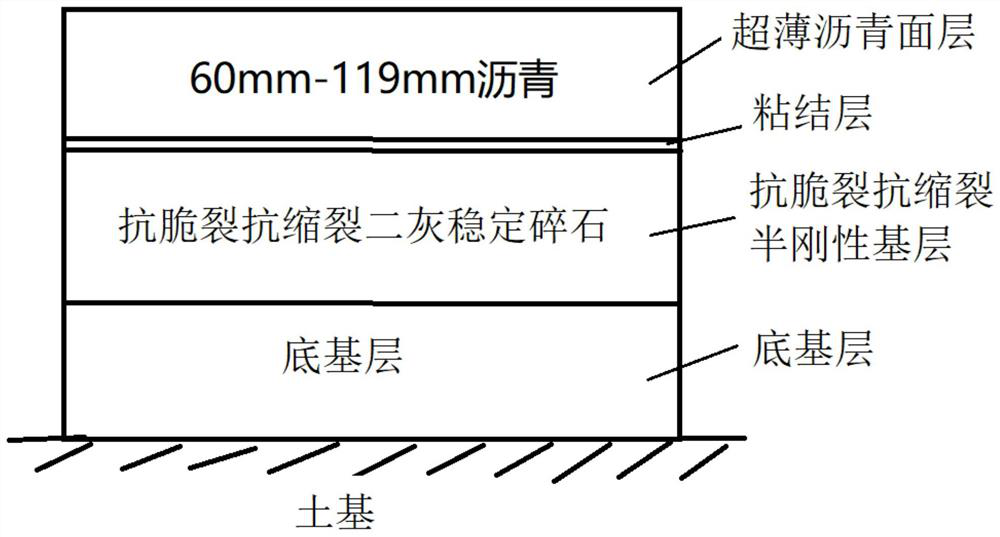

specific Embodiment 3

[0093] Xinglin Expressway K14+000—K17+000 uplink road section experimental construction, asphalt surface layer thickness 100mm; at the same time use bonding layer; at the same time anti-brittle cracking and shrinkage cracking semi-rigid base uses anti-brittle cracking and shrinkage cracking fly ash stabilized macadam ; Simultaneously anti-brittle, anti-shrinkage and anti-shrinkage fly ash stabilized macadam, the compacted thickness of the whole layer is greater than or equal to 280mm; at the same time, slaked lime: fly ash: crushed stone = 7:13:80; at the same time, it is crushed at a temperature of 20°C--30°C Press forming, preferably rolling forming at 25°C; at the same time, the thickness of the base layer is greater than or equal to 360mm; mineral material gradation The mineral material gradation adopts the gradation in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com