Rapid mold changing device of injection molding machine and injection molding machine

An injection molding machine, fast technology, applied in the field of powder metallurgy, can solve the problems of low efficiency of injection molding machine, difficult to effectively guarantee the mold loading time, etc., to achieve the effect of improving efficiency, simplifying the procedure of mold change, and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

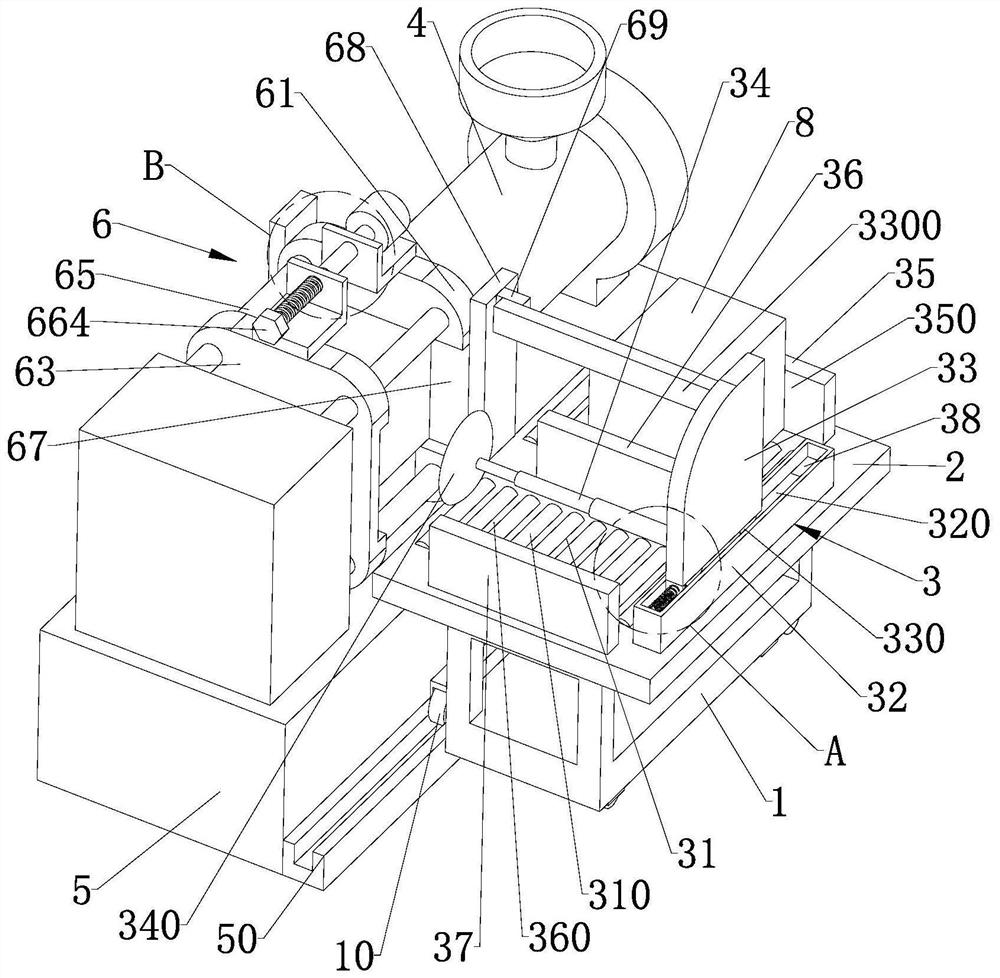

[0029] refer to Figure 1-Figure 3 , the present invention provides the following technical solutions: a rapid mold change device for injection molding machines, including a bottom car 1, an operating table 2 and a mold change assembly 3, the side wall of the bottom car 1 is provided with auxiliary rollers 10; The console 2 is equipped with a mold changing assembly 3; wherein, the cooperation between the bottom car 1 and the mold changing assembly 3 helps the injection molding machine to replace the mold.

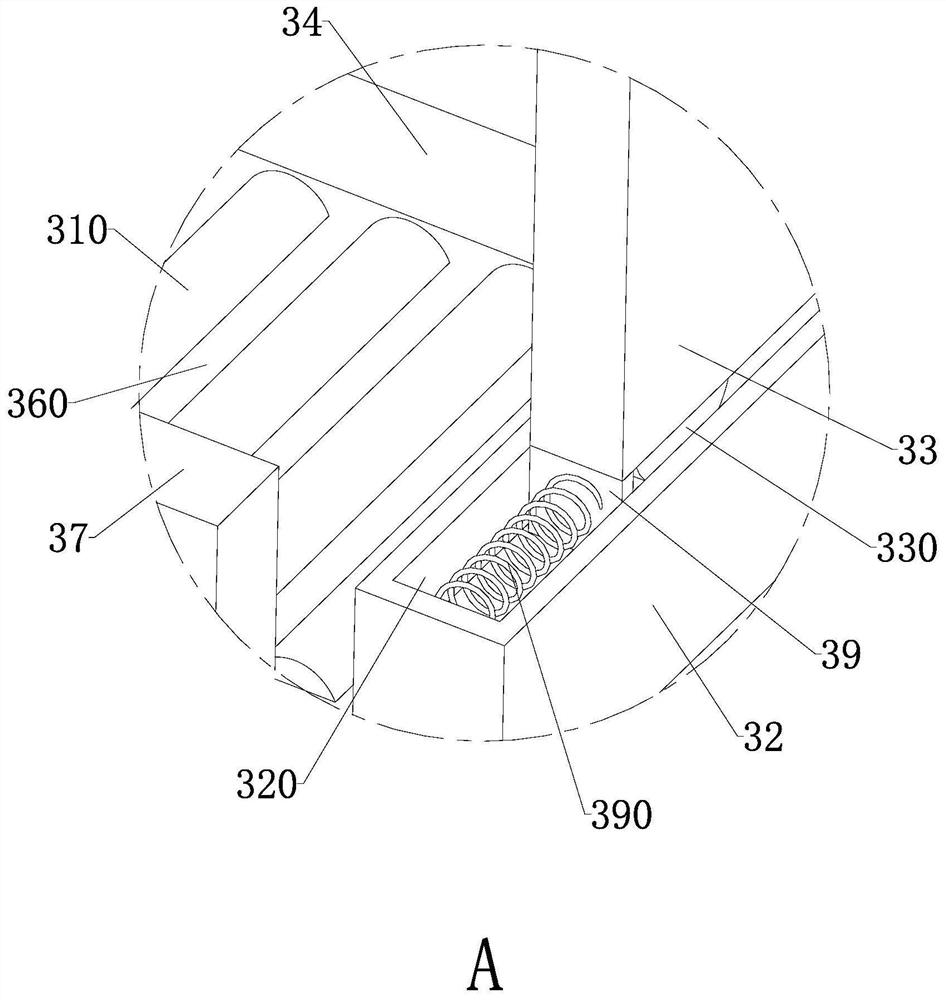

[0030] refer to Figure 1-Figure 2 , the mold change assembly 3 includes two sets of rolling parts 31 arranged on the upper end surface of the console 2, each set of rolling parts 31 is composed of several rollers 310 evenly distributed; wherein, one rolling part 31 is used to help dismounting from the injection molding machine The original mold 7 that comes down moves, and another rolling part 31 is used for helping to move new mold 8 to be assembled on the injection mold...

Embodiment 2

[0037] The present invention also provides an injection molding machine, comprising a body 4 and a base 5, the body 4 is installed on the base 5, and a clamping mechanism 6 arranged on the body 4 for fixing the mould, the side wall of the base 5 is provided with a slideway 50 , the auxiliary roller 10 slides in the slideway 50; wherein, the sliding and the auxiliary roller 10 cooperate with each other, so that the bottom vehicle 1 will not shift when moving, thereby making the mold changing process more smooth.

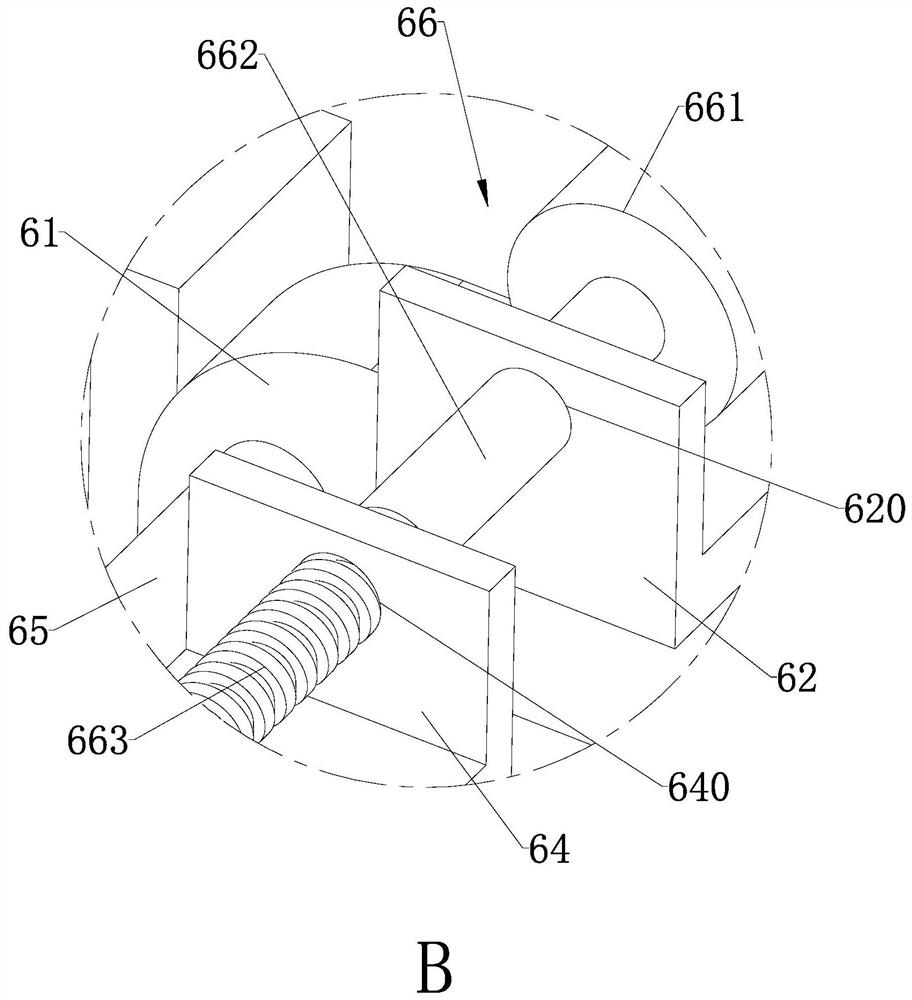

[0038] refer to figure 1 and image 3 , the clamping mechanism 6 includes a fixed template 61, a fixed part 62 arranged on the fixed template 61, a movable template 63, a movable part 64 arranged on the movable template 63, a guide rod 65 and an adjustment for connecting the fixed part 62 and the movable part 64 Part 66, the opposite side walls of the fixed template 61 and the movable template 63 are provided with grooves 67 that match the mould. Offset, thereby aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com