Cattle house with automatic cleaning mechanism

A driving mechanism and cowshed technology, applied in animal houses, animal feeding devices, cleaning hollow objects, etc., can solve the problems of low efficiency and high labor intensity of troughs, reduce labor intensity, and improve the efficiency of cleaning feed Quantity, convenient physical examination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

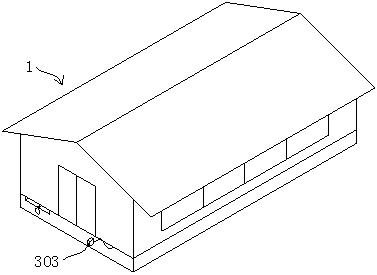

[0012] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment proposes a cowshed with an automatic cleaning mechanism, including a cowshed body 1, a feeding trough 2 for placing feed is arranged in the cowshed body 1, and a feeding trough 2 for feeding food is arranged in the cowshed body 1. The automatic cleaning mechanism 4 for cleaning the residual feed in the tank 2, the cowshed body 1 is also provided with a drive mechanism 3 that drives the automatic cleaning mechanism 4 to and fro; Driven to clean the residual feed in the feeding trough 2, and the cleaning and fixing part is used to fix the neck of the cattle after the structural change. The cleaning and fixing part is provided with a positioning part, which is used for cleaning the limit Fixation before and after changes in site structure.

Embodiment 2

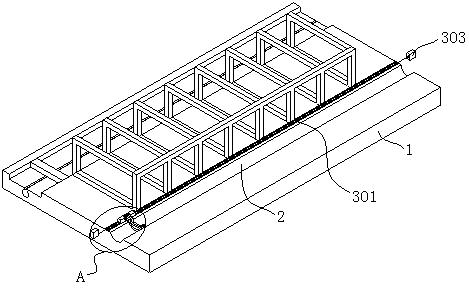

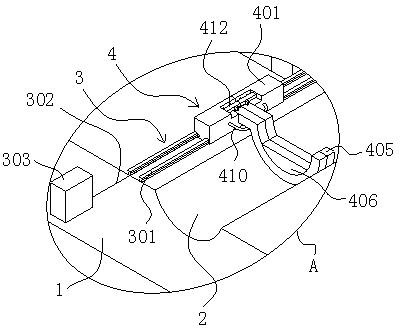

[0013] Embodiment 2: The scheme in Embodiment 1 is further introduced below in conjunction with specific working methods, see the following description for details: as figure 2 and image 3 As shown, as a preferred embodiment, on the basis of the above method, further, the driving mechanism 3 includes two T-shaped guide rails 301, and the two T-shaped guide rails 301 are fixedly installed in the cowshed body 1. By setting the T-shaped The guide rail 301 can limit the moving track of the automatic cleaning mechanism 4 , thereby improving the stability of the automatic cleaning mechanism 4 during the movement.

[0014] Such as image 3 , Figure 4 and Figure 5 As shown, as a preferred embodiment, on the basis of the above method, further, the cleaning and fixing part includes two sliders 401, and the bottoms of the two sliders 401 are provided with two T-shaped slide grooves 418, and the T-shaped slides The slot 418 is slidingly connected to the outer surface of the T-shap...

Embodiment 3

[0022] Embodiment 3: The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the description below for details: Specifically, when the cowshed with the automatic cleaning mechanism is working / using, it includes The following steps: step 1, cleaning of the feeding trough 2: first start the two hoists 303, and make the two hoists 303 respectively in the state of retracting and releasing the rope 302, and the retracted rope 302 pulls the slider 401 connected to it One slider 401 drives the other slider 401 to move, so that the two sliders 401 drive the two cleaning scrapers 405 to move in the same direction, and the residual feed in the feeding trough 2 is scraped and cleaned by the cleaning scrapers 405 ; Step 2, fixing the neck of the cow, the automatic cleaning mechanism 4 from Figure 4 switch to Figure 6 Form, first pull the stopper 414 to separate the spring pin 415 from the slot 416, press the telescopin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com