Drip irrigation equipment for vegetable greenhouse planting

A vegetable greenhouse and equipment technology, applied in the field of drip irrigation equipment for vegetable greenhouse planting, can solve the problems of low equipment flexibility, splashing of drip irrigation liquid, inconvenient control of drip irrigation liquid flow rate, etc., and achieve the effect of increasing flexibility and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

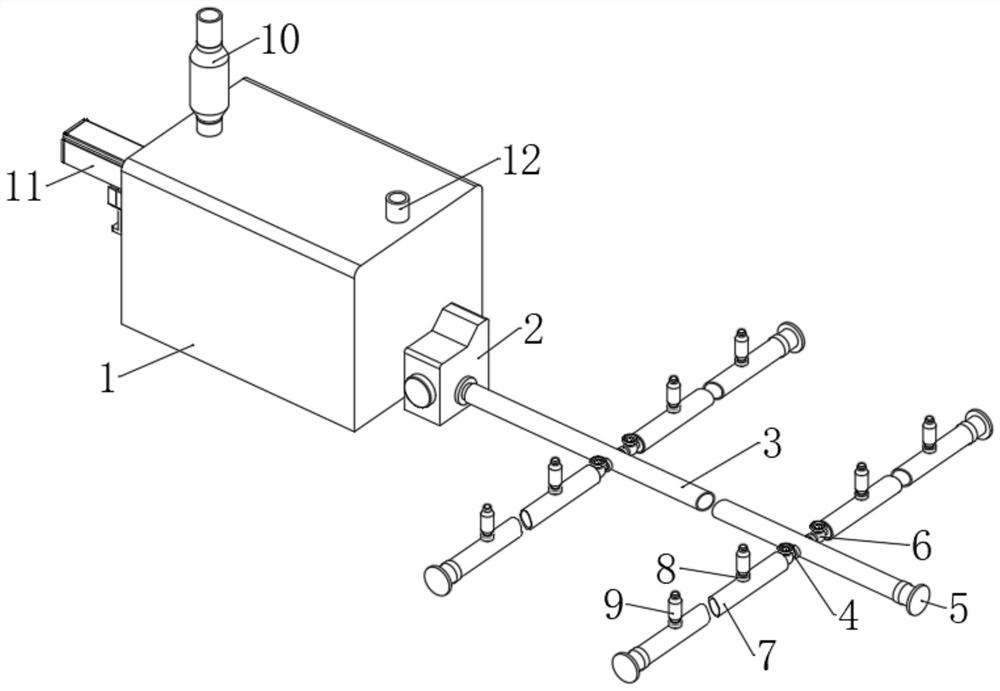

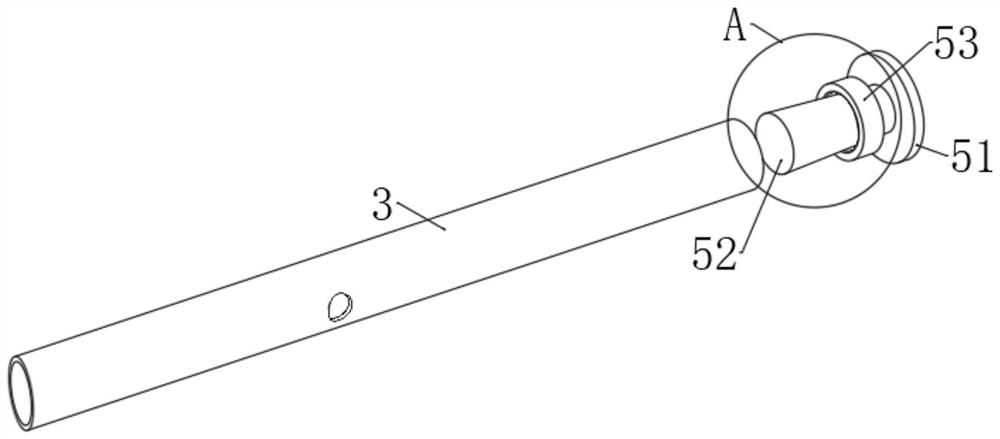

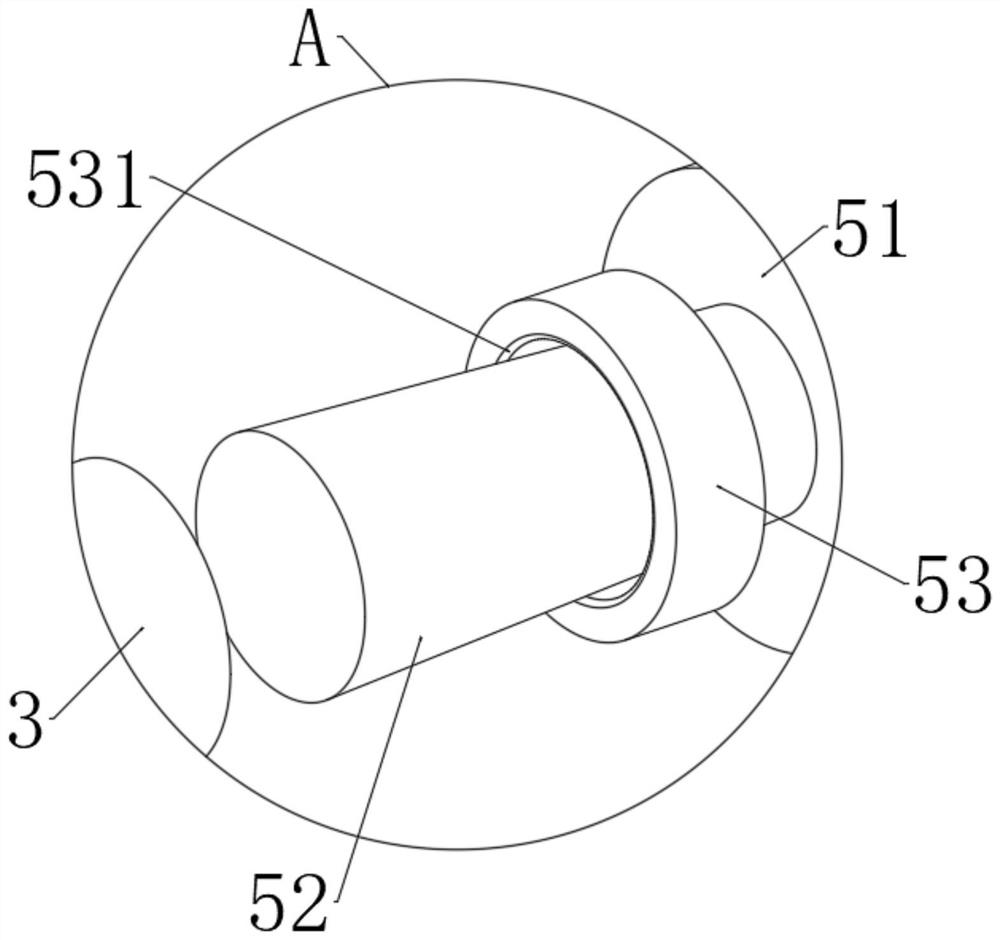

[0035] Example: such as Figure 1-8 As shown, the present invention provides a kind of drip irrigation equipment for vegetable greenhouse planting, including a liquid storage tank 1, the bottom of the liquid storage tank 1 is fixedly installed with a booster pump 2 through a pipeline, and the booster pump 2 can be opened to increase the pressure on the storage tank. The output pressure of the liquid in the liquid tank 1, the output end of the booster pump 2 is fixedly installed with a main pipe 3, wherein the main pipe 3 is a hose structure, and the end of the main pipe 3 away from the booster pump 2 is provided with a blocking assembly 5 , the main pipe 3 is horizontally provided with a first connecting assembly 4, wherein, a plurality of first connecting assemblies 4 can be provided according to the needs of users and the planting area of the vegetable greenhouse, and the side of the first connecting assembly 4 away from the main pipe 3 Both are fixedly installed with a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com