Hydraulic inner formwork of assembled corrugated steel web combined box girder

A corrugated steel web and combination box technology, which is applied in the erection/assembly of bridges, formwork/template/work frame, bridges, etc. The effect of reducing the difficulty of operation and labor intensity, improving the reuse rate and shortening the assembly period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

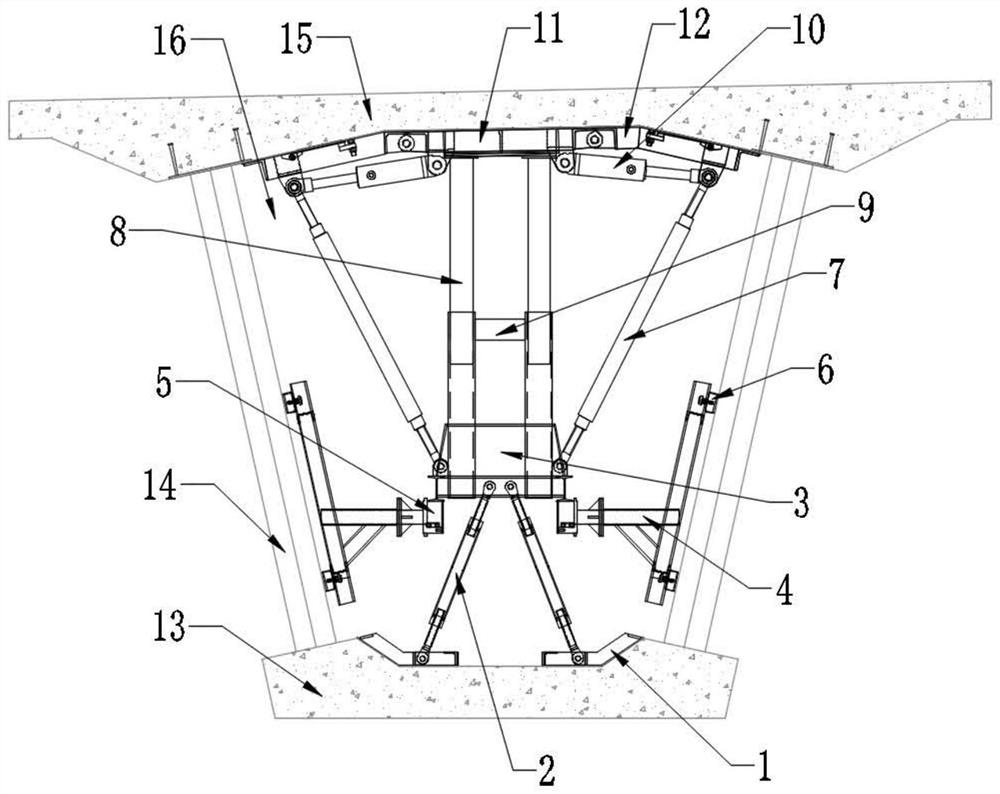

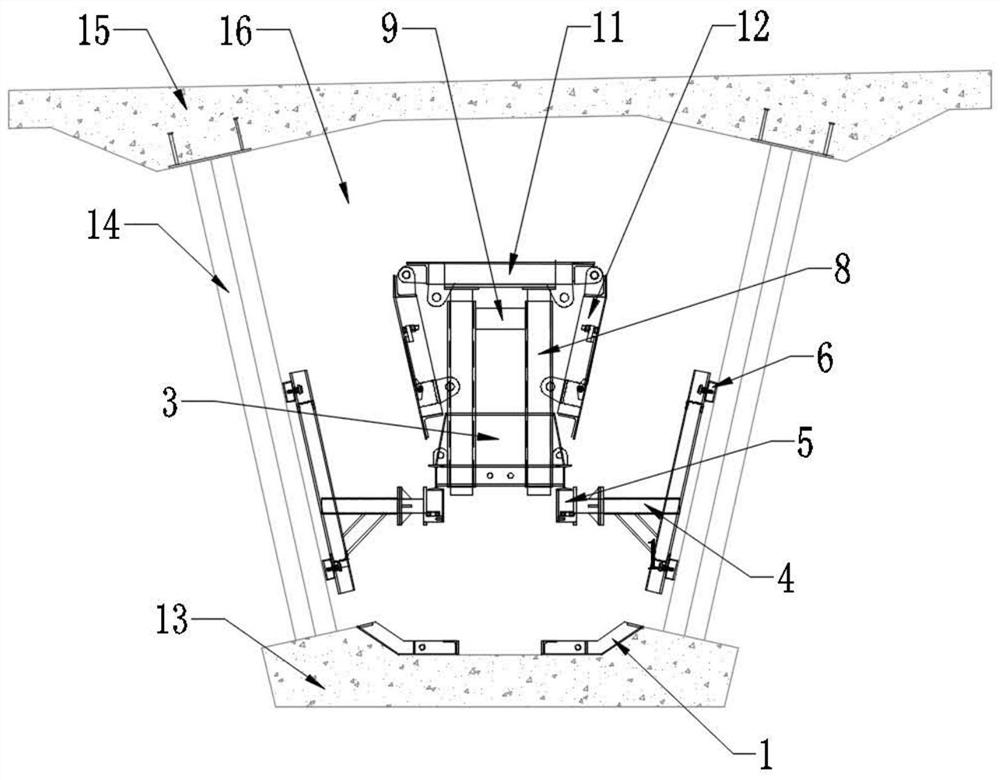

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

[0016] like figure 1 As shown, a hydraulic inner formwork of an assembled corrugated steel web composite box girder includes corrugated steel webs 14, which are symmetrically supported between the concrete top plate 15 and the concrete bottom plate 13, and the corrugated steel webs The plate 14, the concrete top plate 15, and the concrete bottom plate 13 together constitute the box chamber 16 of the box girder; the upper surface of the concrete bottom plate 13 in the box chamber 16 is fixedly provided with a lower bottom mold 1, and the lower bottom mold 1 is symmetrically movably connected with upwards. The extended first support rod 2, the top of the first support rod 2 is movably connected with the sliding beam 3; the sliding beam 3 is placed on the symmetrical track pulley 5, and the track pulley 5 passes through the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com