Maintenance plate system capable of changing form along with working conditions

A variable and morphological technology, applied in the field of vehicle maintenance, can solve the problems of difficult control and easy movement of the bottom frame, and achieve the effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

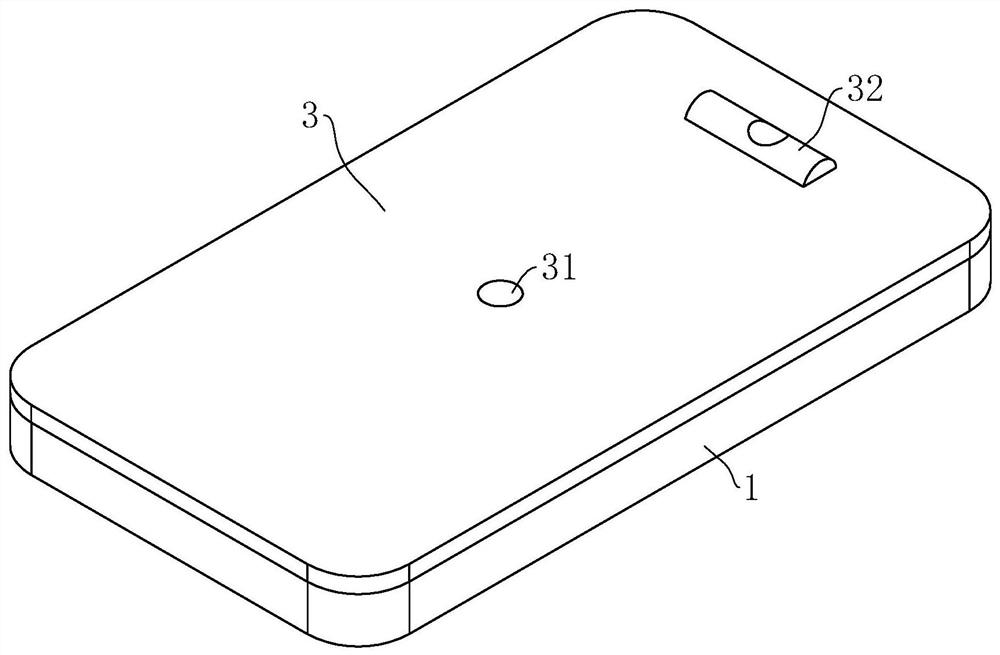

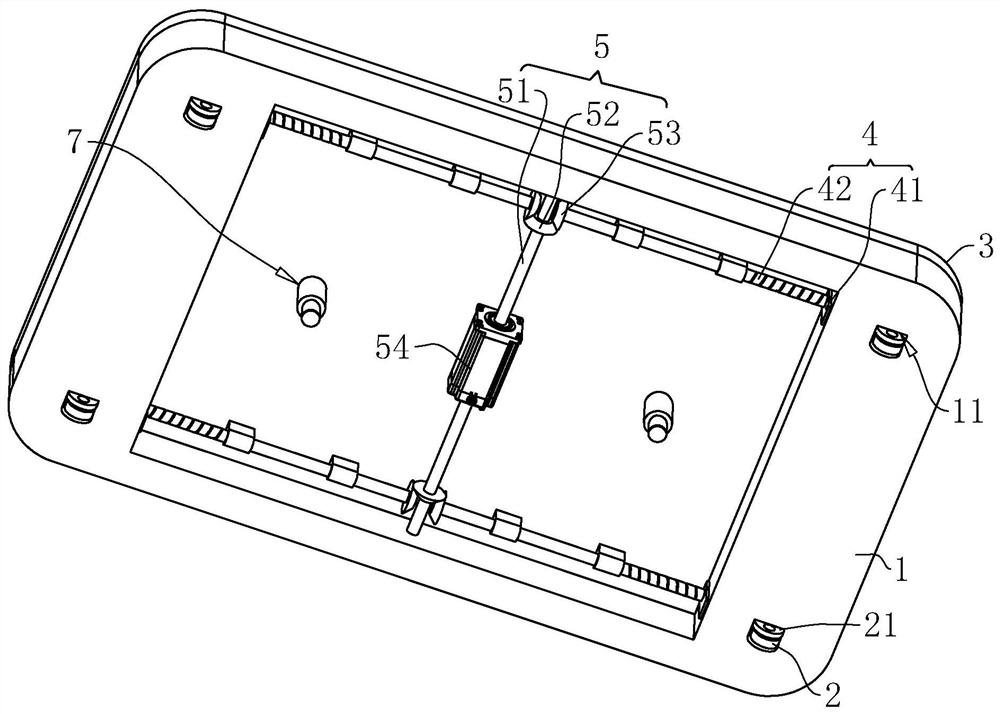

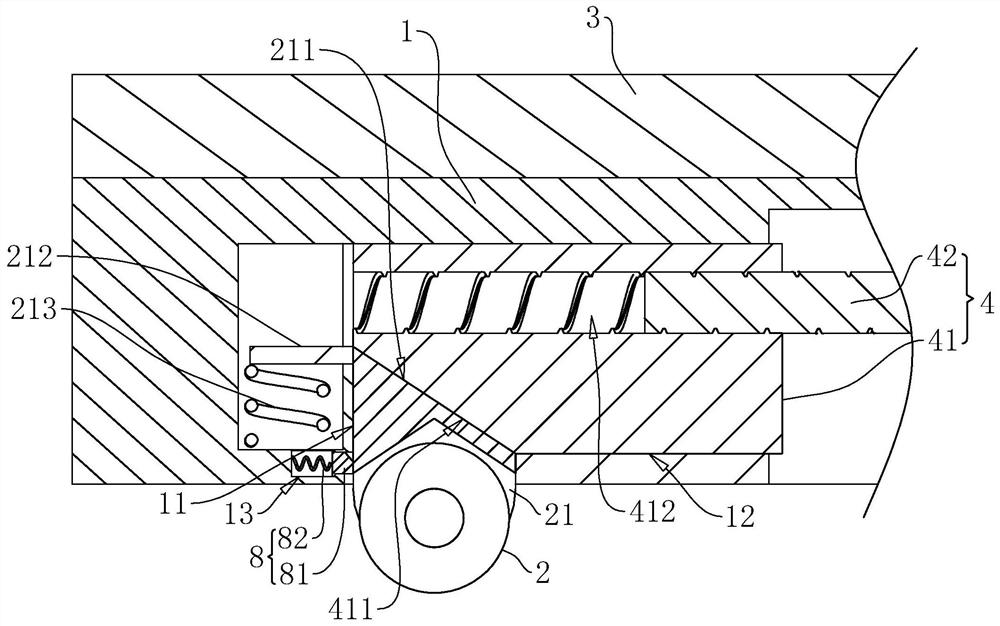

[0041] A repair panel system with variable shape according to working conditions, refer tofigure 1 and figure 2 , comprising a floor frame 1, the bottom of the floor frame 1 is provided with four wheels 2, wheel frames 21 are installed on the wheels 2, the four wheels 2 are respectively arranged at the four corners of the floor frame 1, and the wheels 2 are connected in rotation On the wheel frame 21, the wheel 2 is installed on the floor frame 1 through the wheel frame 21. The upper surface of the bottom frame 1 is provided with a turntable frame 3, the turntable frame 3 and the bottom frame 1 are plate-shaped and arranged in parallel, the turntable frame 3 is located above the bottom frame 1, and the center of the upper surface of the bottom frame 1 is fixed. There is a vertical rotating shaft 31, and the turntable frame 3 is rotatably connected to the base frame 1 by the rotating shaft 31. The maintenance personnel lie on the upper surface of the turntable frame 3, can ro...

Embodiment 2

[0049] A repair panel system with variable shape according to working conditions, refer to Figure 6 , the difference from Embodiment 1 is that: the inside of the rotating shaft 31 is pierced with an operating rod 9, and the operating rod 9 is rotatably connected to the floor frame 1. The upper end of the operating rod 9 extends out of the rotating shaft 31 and is located above the rotating plate frame 3. The upper end of lever 9 is fixedly connected with handwheel 92, and operating lever 9 can be rotated by handwheel 92. The lower end of operating lever 9 is provided with transmission gear 91 connected with main shaft 51. Transmission gear 91 is a bevel gear. One transmission gear 91 is fixed on the shaft, another transmission gear 91 is coaxially fixed on the operating lever 9, and the two transmission gears 91 mesh, and then the staff can rotate the operating lever 9 above the turret, and the operating lever 9 passes through the two transmission gears. 91 drives the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com