Minimally invasive surgery needle-holding forceps with force sensing function

A sensory function and minimally invasive surgery technology, applied in surgery, trocars, medical science, etc., can solve the problems of easily torn tissues, limited operating space of minimally invasive surgical instruments, and the inability to perceive the tightness of knots, etc., to achieve improved Sensitivity, improved safety, and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

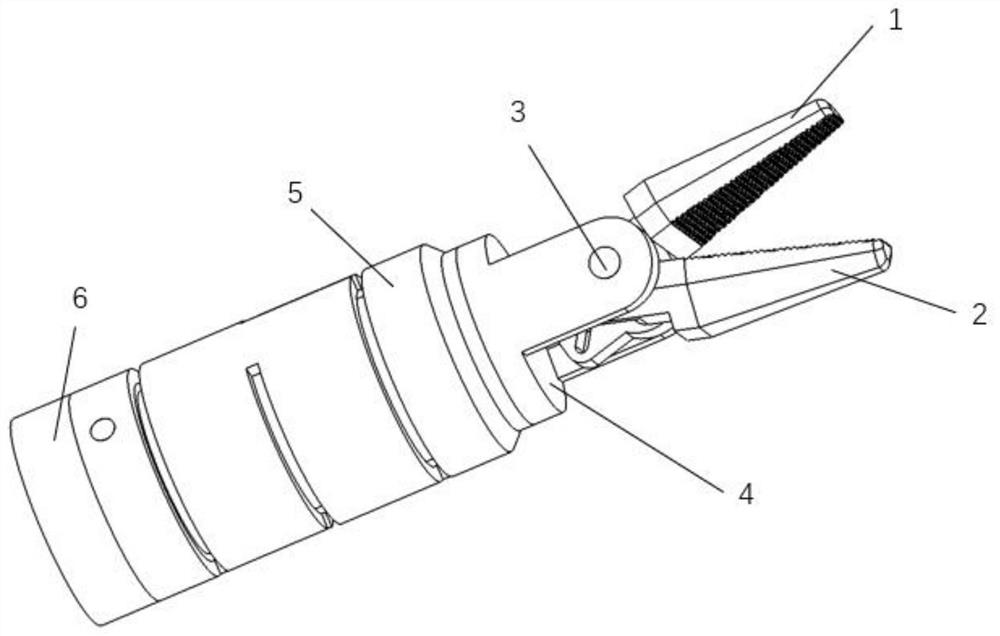

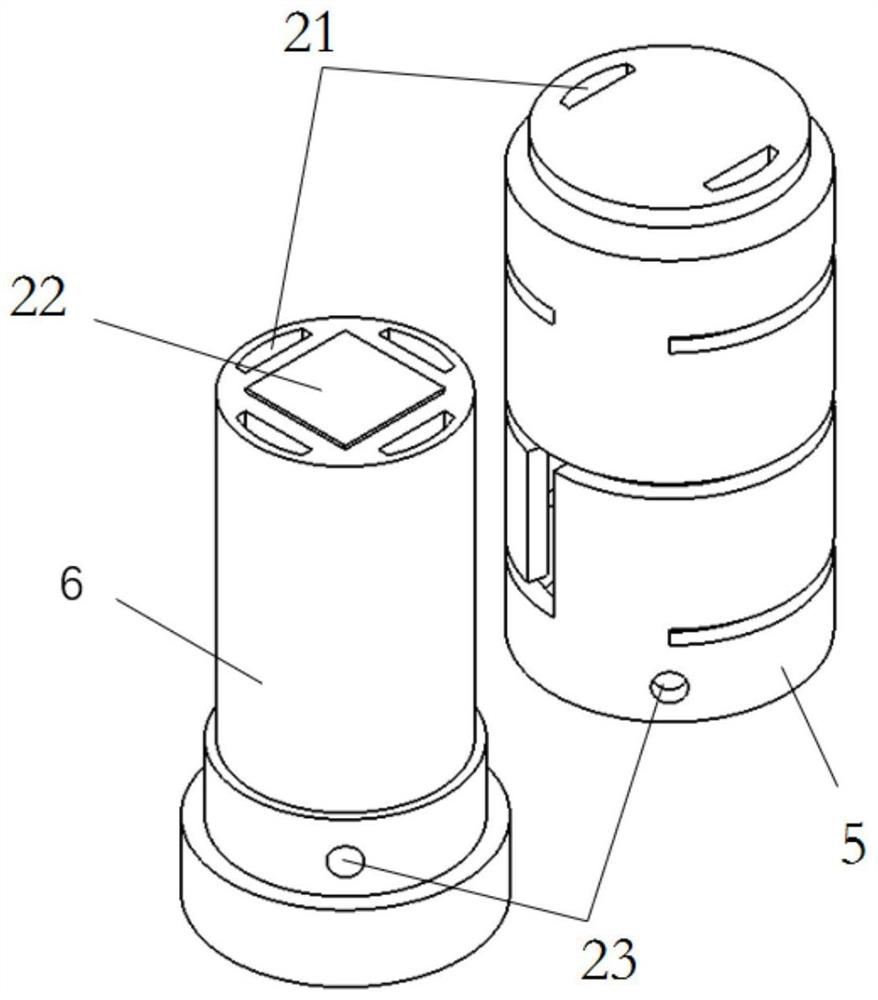

[0028] refer to Figure 1 to Figure 5 As shown, the present invention discloses a needle-holding forceps for minimally invasive surgery with a force-sensing function, which includes a clamp part and a force-sensing part.

[0029] Wherein, the above-mentioned clamp part is used for clamping the surgical suture needle, and the above-mentioned clamp part includes the wrist support 4 and the upper clamp 1 and the lower clamp 2 that cooperate with each other, and the upper clamp 1 and the lower clamp 2 are all provided with There is a connecting hole 3, and a fixing pin is pierced in the connecting hole 3 so that the upper clamp 1 and the lower clamp 2 are fixed on the wrist support 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com