Base of detection device and processing method thereof

A technology of a detection device and a processing method, which is applied to electromagnetic measurement devices, electric/magnetic diameter measurement, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

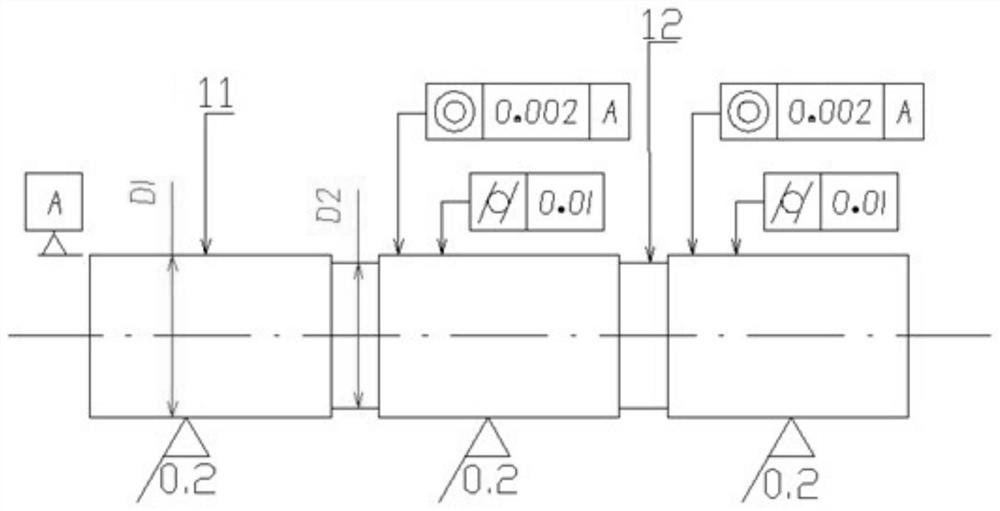

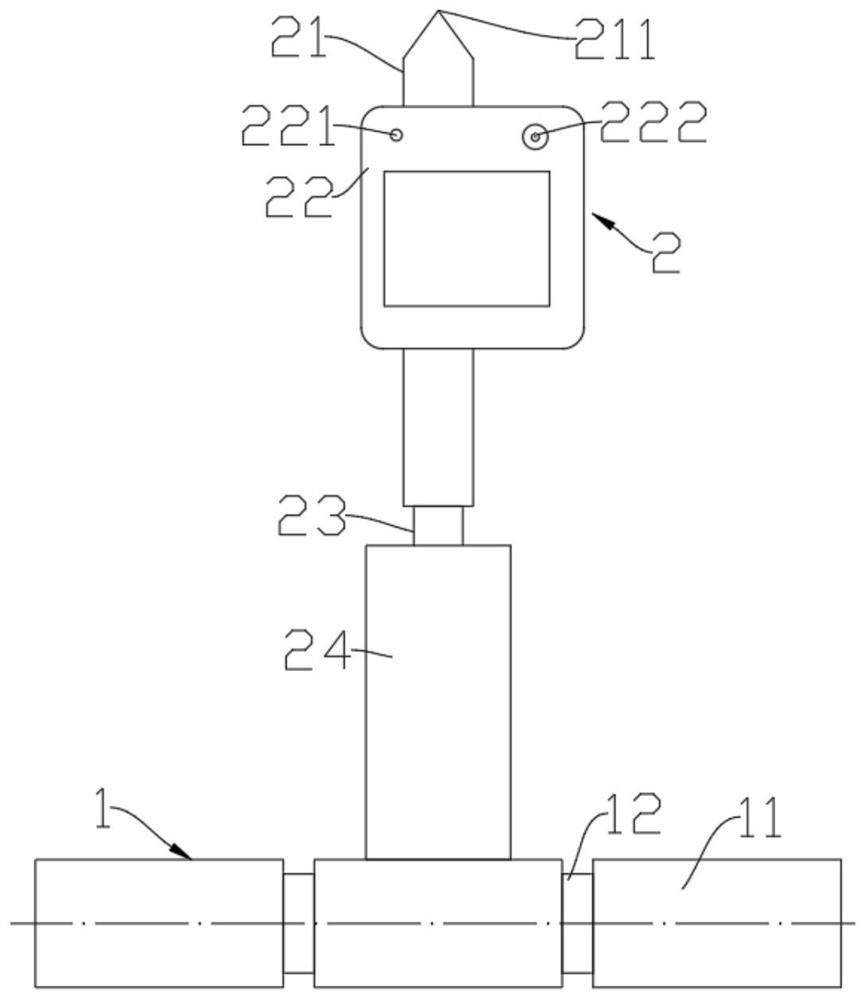

[0036] Please refer to figure 1 , figure 2 , the present embodiment provides a base of a detection device, including n+1 conductive segments 11 and n insulating segments 12, the conductive segment is a cylinder, n≥2, and n is an even number; it also includes a display device, The display device includes a display lamp 221, and n+1 conductive segments control the state of the display lamp through a control circuit; the control circuit includes an AND gate, a power supply, and two optocouplers, and the first input terminals of the two optocouplers are connected to the positive pole of the power supply , the second input terminals of the two optocouplers are respectively connected to the conductive segments at both ends, the negative pole of the power supply is connected to the conductive segment in the middle, the first output terminals of the two optocouplers are connected to each other and grounded, and the second terminals of the two optocouplers The output end is connected...

Embodiment 2

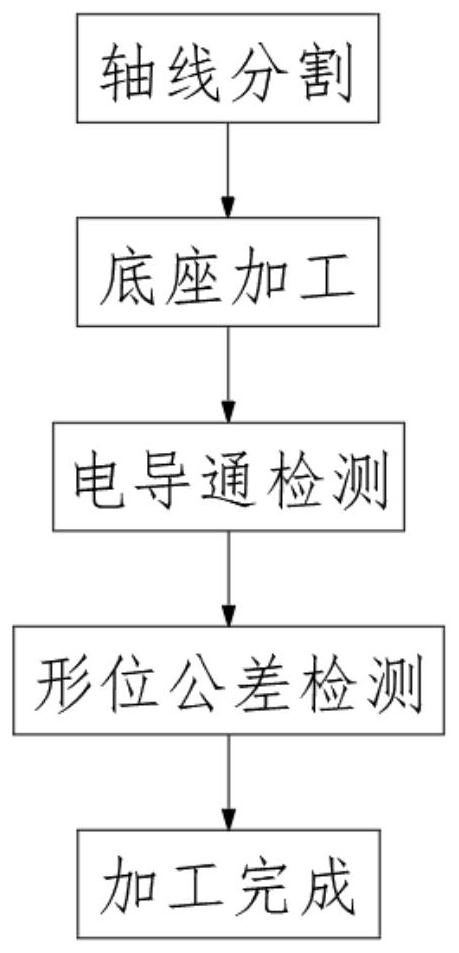

[0048] Please refer to Figure 1-Figure 4 , the present embodiment provides a processing method for processing the base of the detection device described in Embodiment 1, comprising the following steps:

[0049] Axis division: according to the axial length of the measured hole, the axis of the base 1 of the detection device is divided into a plurality of conductive segments 11 and a plurality of insulating segments 12;

[0050] Base processing: connect n+1 conductive segments 11 and n insulating segments 12 to process into base 1;

[0051] Electrical conduction detection: use a conductive detection device to conduct a conductive detection experiment on the processed base 1;

[0052] Geometric tolerance detection: detect the geometrical tolerance of the base 1 after processing, including the surface roughness of the base 1, the coaxiality of the cylindricity of the outer circle, and the perpendicularity between the two ends of the outer circle and the axis;

[0053] After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com