Automobile magneto-rheological brake

A magneto-rheological and brake technology, applied in the direction of brake types, liquid resistance brakes, mechanical equipment, etc., can solve the problem that the braking force is small and cannot meet the requirements of automobile braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

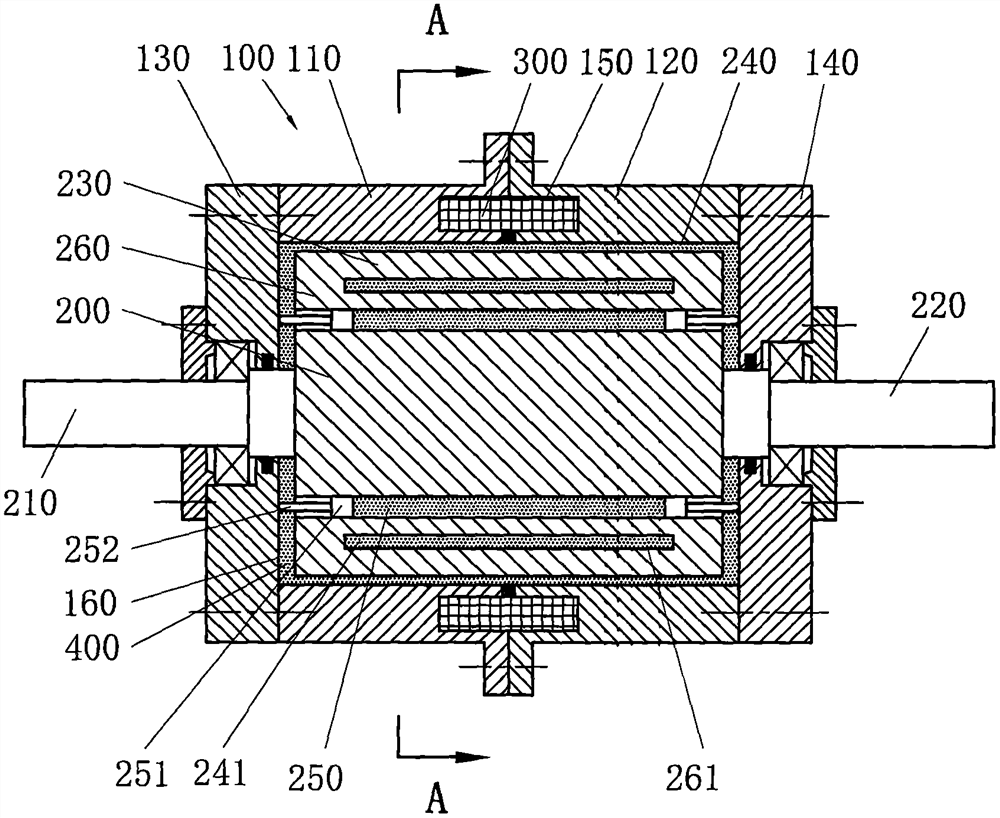

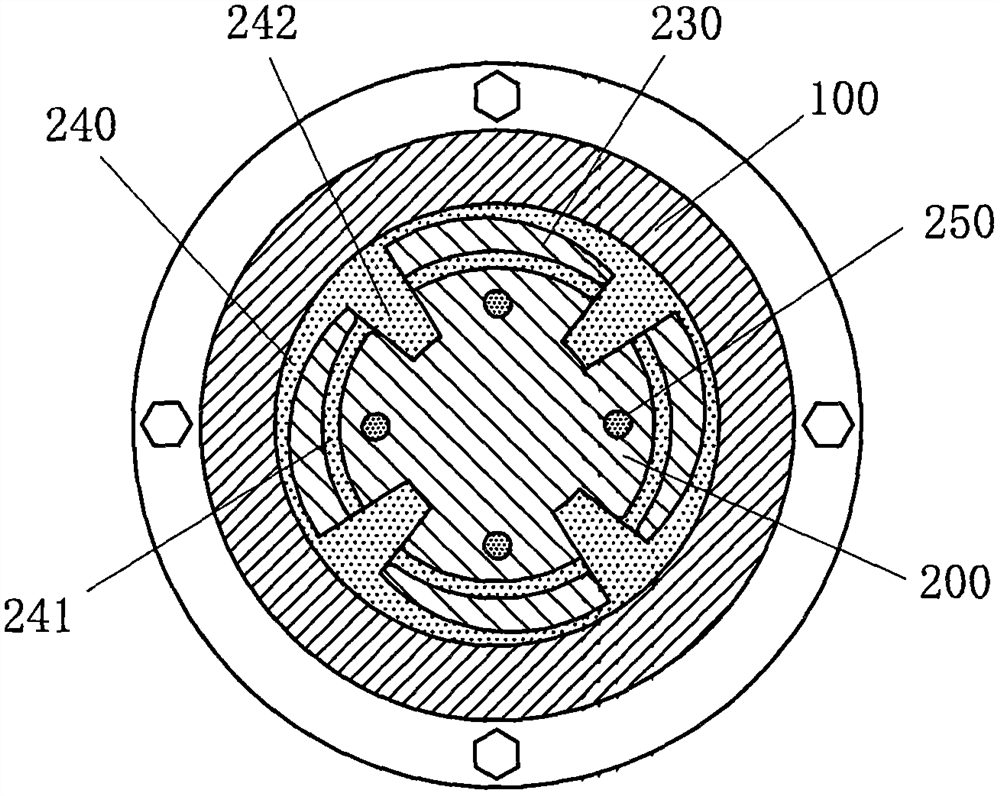

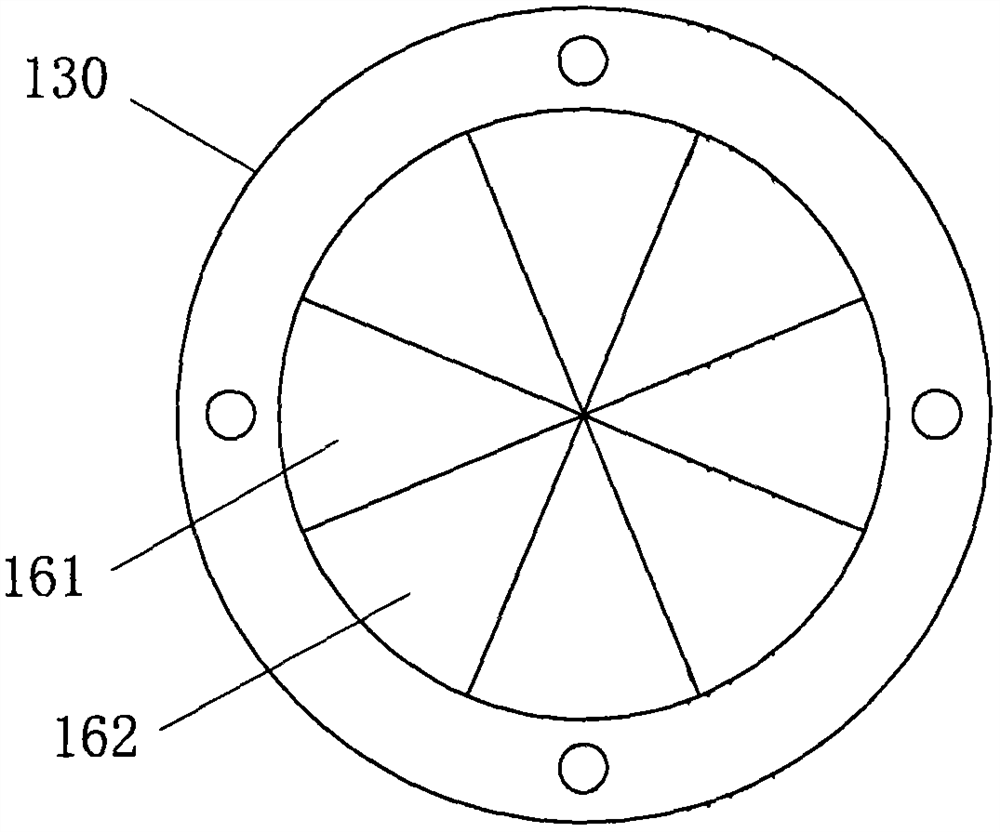

[0022] The automobile magneto-rheological brake includes a stator and a rotor. The stator is provided with a placement chamber, the rotor is arranged in the placement chamber, and the left and right ends of the stator are respectively provided with a left end cover and a right end cover to close the placement chamber. The stator is provided with a coil, and the placement cavity is filled with magnetorheological fluid; the two ends of the rotor are respectively provided with an input shaft and an output shaft, and the input shaft passes through the left end cover and is rotatably connected with the left end cover. The output shaft passes through the right end cover and is rotatably connected with the right end cover; at least two blades are evenly distributed on the outer circumference of the rotor, and a first circulation channel is left between the outer circumference of the blades and the inner side wall of the placement cavity, so There is at least one hydraulic chamber pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com