Masonry rapid slurry laying tool capable of adapting to wall thickness and slurry laying method

A technology of grouting and tools, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve problems such as incompleteness, unevenness, and unevenness, and achieve fast paving speed, straight mortar joints, and consistent thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

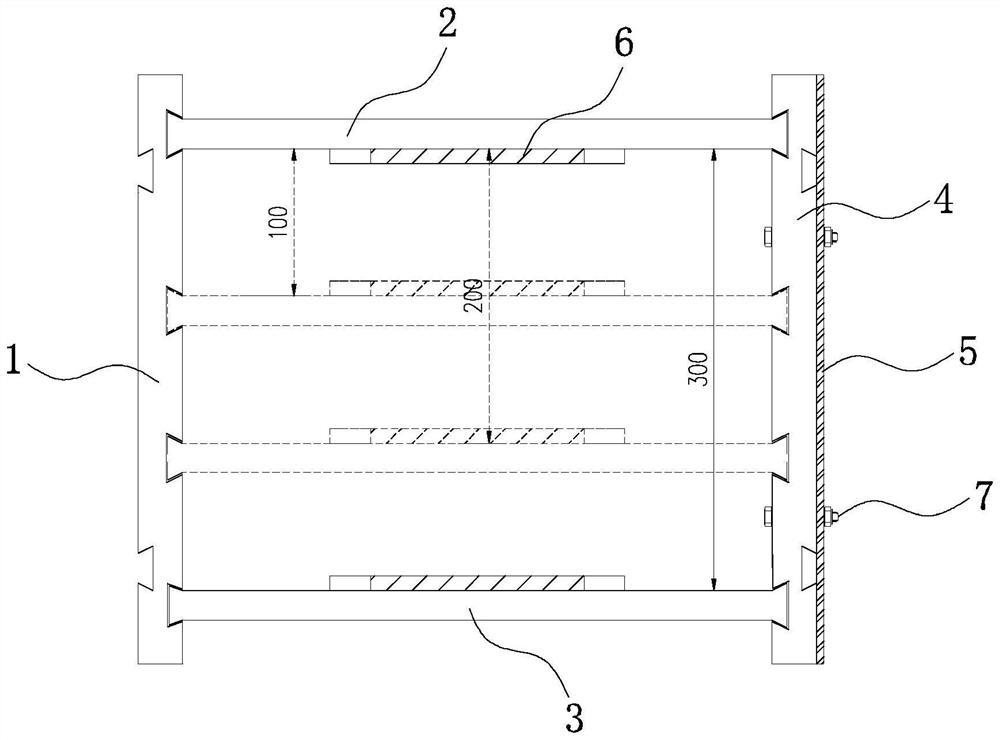

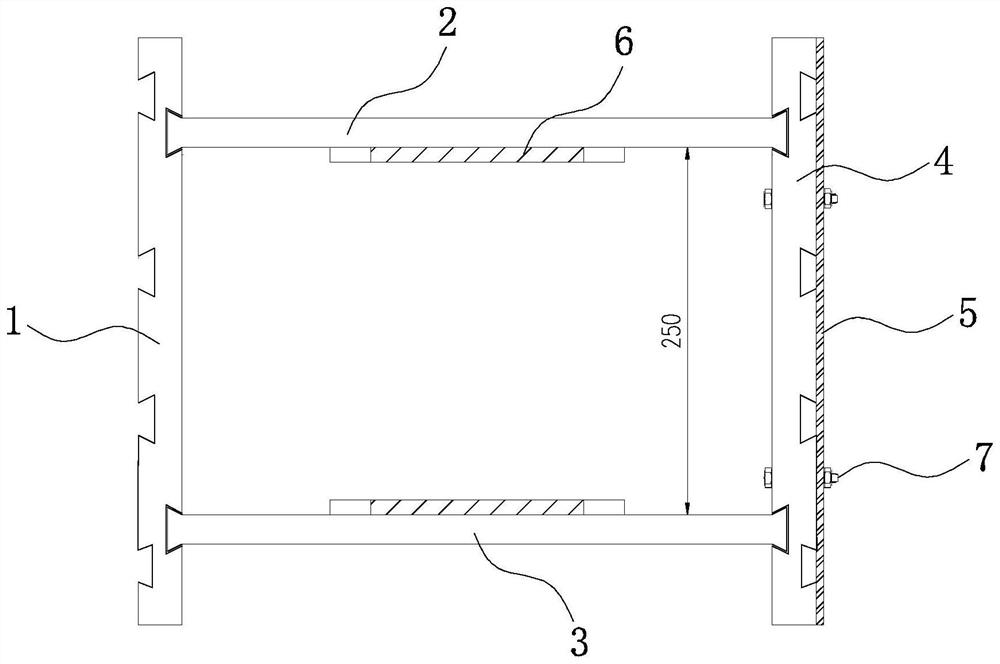

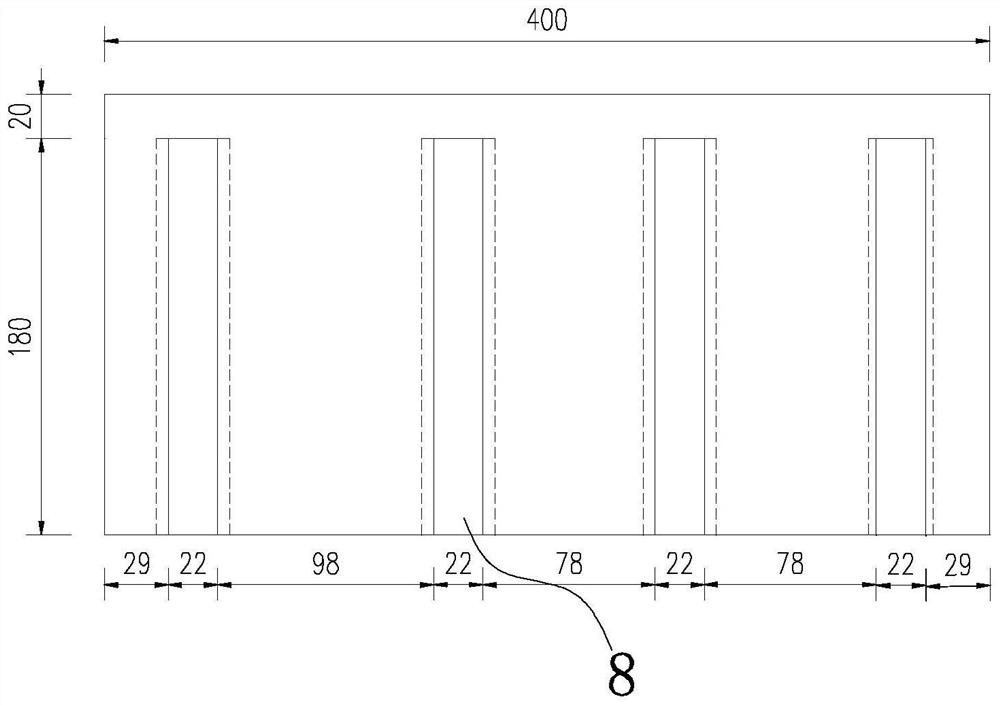

[0035] like Figure 1 to Figure 13 As shown, a fast grouting tool for masonry that can adapt to the wall thickness includes a front double-sided groove plate 1, a fixed plate 2, a wall thickness adjusting plate 3, a rear double-sided groove plate 4 and a scraper 5; The wide faces of the front-end double-sided grooved plate 1 and the rear-end double-sided grooved plate 4 are all processed with tongue and groove 8 corresponding to the end, the front-end double-sided grooved plate 1 and the rear-end double-sided grooved plate 4 are arranged in parallel, and the The fixed board 2 and the wall thickness adjusting board 3 are inserted into the tenons and grooves 8 of the front double-sided grooved plate 1 and the rear-end double-sided grooved plate 4 respectively through the tenons 9 provided at both ends to form a mortise and tenon structure connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com