Automatic production equipment capable of realizing glass grabbing

A technology for production equipment and glass, applied in lighting and heating equipment, conveyor objects, furnaces, etc., can solve problems such as product quality decline, lack of transmission and conduction functions, lack of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

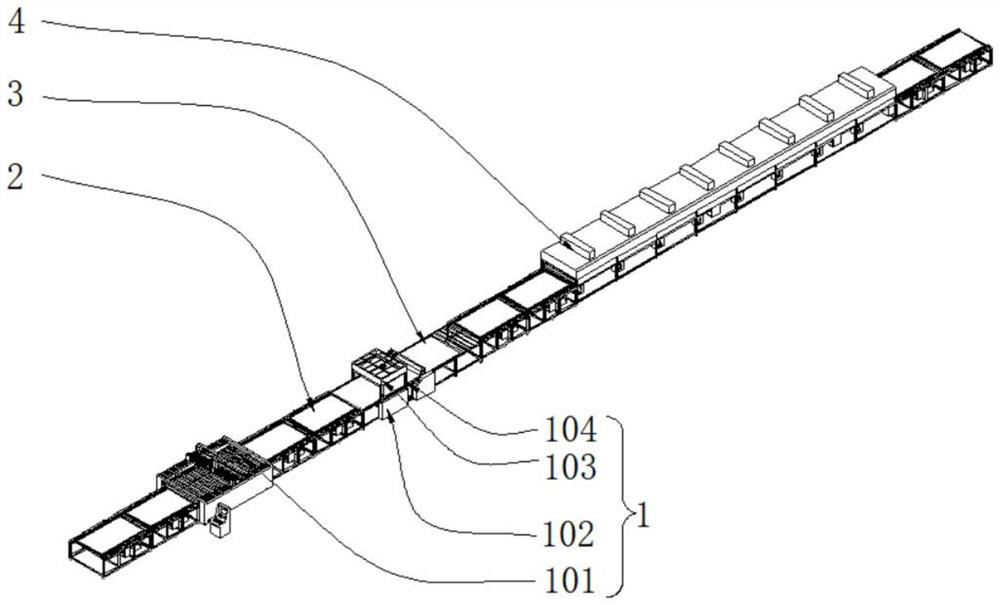

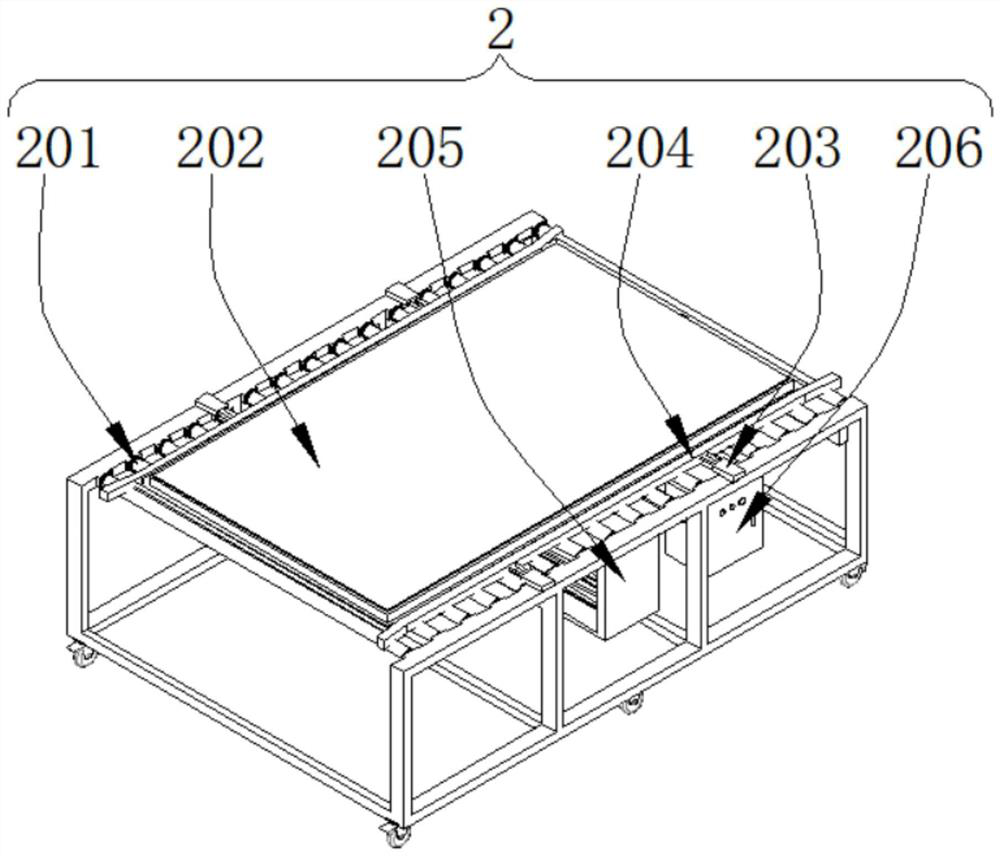

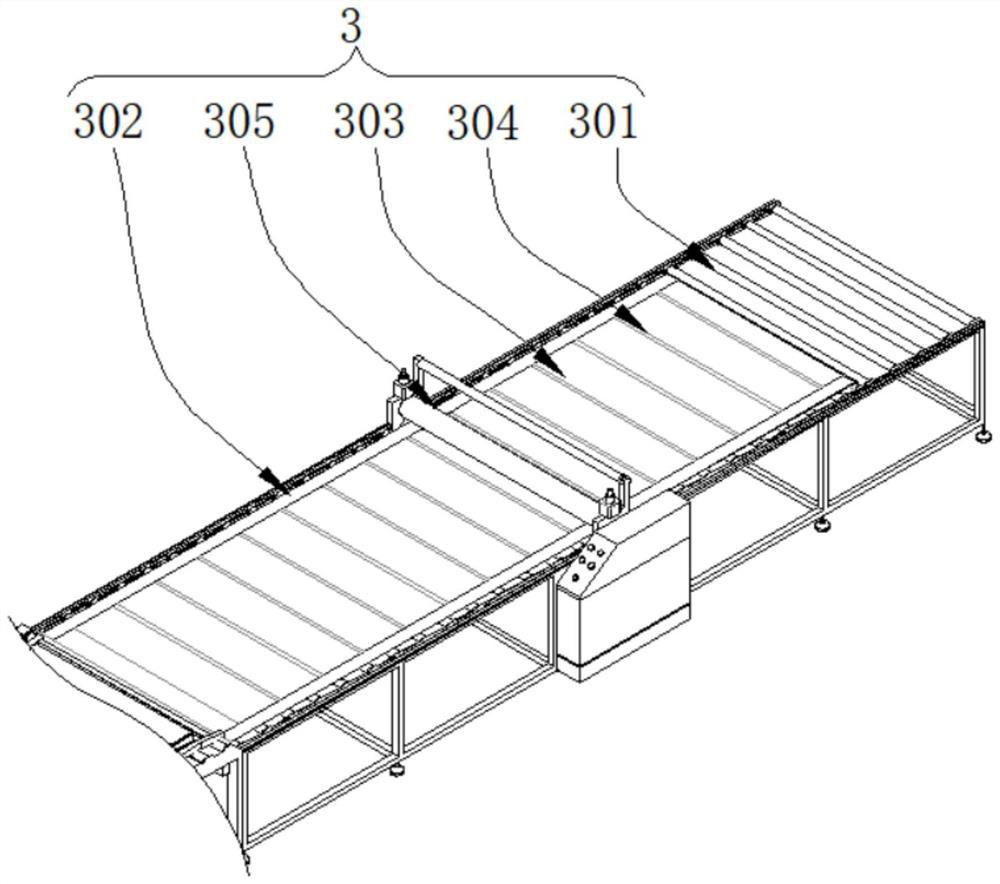

[0023] Such as figure 1 As shown, the glass grasping automatic production equipment includes: adjusting the grasping mechanism 1; the two sides of the adjusting grasping mechanism 1 are connected with a clamping transmission mechanism 2, and one end of the clamping transmission mechanism 2 is connected with a stable conveying mechanism 3, and the clamping One end of the conduction mechanism 2 is connected with a built-in baking mechanism 4, and the adjusting grabbing mechanism 1 includes a dispenser 101, a bottom platform 102, a grabbing platform 103 and a lift cylinder 104, and the right side of the dispenser 101 is provided with a bottom platform 102 , the top of the bottom platform 102 is provided with a grabbing platform 103, and the bottom of the grabbing platform 103 is provided with a lifting cylinder 104 around the bottom, the grabbing platform 103 forms a lifting structure through the lifting cylinder 104 and the bottom platform 102, and the dispenser 101 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com