Double-motor two-gear electric drive axle structure

An electric drive, dual-motor technology, applied in electric power units, power units, control devices, etc., can solve the problems of insufficiently compact built-in structure, inability to meet speed change requirements, poor shifting comfort, etc. The effect of blocking the impact and improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

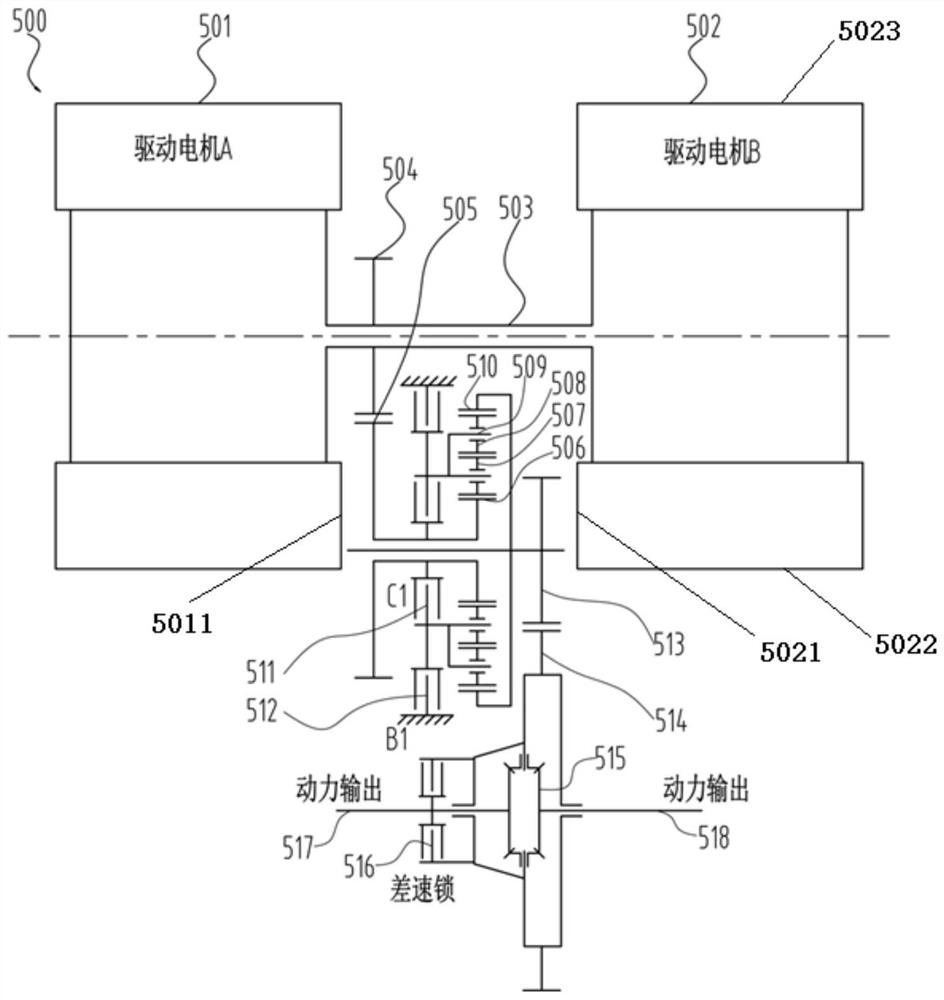

[0027] According to a preferred embodiment of the present invention, see figure 1 , provides a dual-motor two-speed electric drive axle structure 500, which is characterized in that it includes:

[0028] The first drive motor 501 and the second drive motor 502 are arranged at intervals from each other;

[0029] The two-speed reduction mechanism includes an input shaft 503, a first driving gear 504, a first driven gear 505, a first countershaft, a second countershaft, a clutch 511, a brake 512, a double-star planetary row, a second driving gear 513 and a second countershaft. Two driven gears 514, the two ends of the input shaft 503 are respectively connected to the first driving motor 501 and the second driving motor 502, the first driving gear 504 is connected to the input shaft 503, and the first driven gear 505 is connected to The first intermediate shaft meshes with the first driving gear 504. The double-star planetary row includes a sun gear 506, a first planetary gear 50...

Embodiment approach

[0033] According to yet another preferred embodiment of the present invention, the first drive motor 501 and the second drive motor 502 are arranged symmetrically at both ends of the input shaft 503 . Advantageously, the length of the input shaft 503 limits the arrangement range of the two-speed reduction mechanism, the differential case, and the differential lock 516 , thereby realizing an overall compact layout.

[0034] According to yet another preferred embodiment of the present invention, the first intermediate shaft and the second intermediate shaft are arranged on the boundary defined by the adjacent side surfaces 5011, 5021 and the upper and lower end surfaces 5023, 5022 of the first driving motor 501 and the second driving motor 502. There is a predetermined distance between the first drive motor 501 and the second drive motor 502 in the space and between the two ends. It can be understood that the first intermediate shaft and the second intermediate shaft are located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com