Automatic mechanical part stamping equipment

A technology for stamping equipment and mechanical parts, applied in the field of stamping equipment for automated mechanical parts, can solve problems such as single function, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

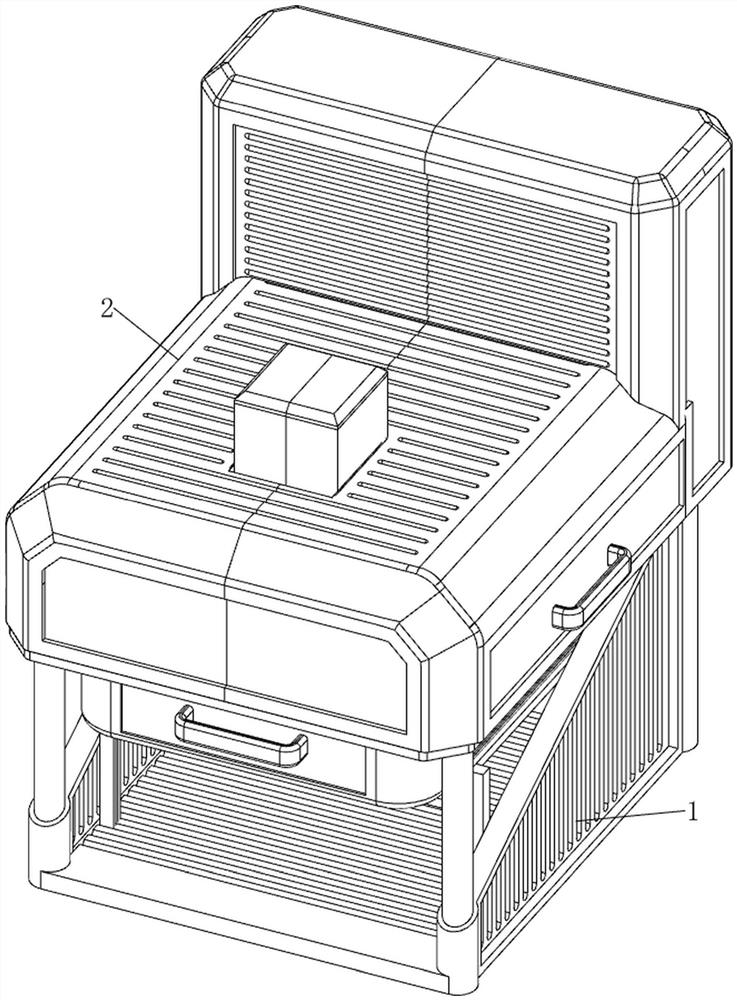

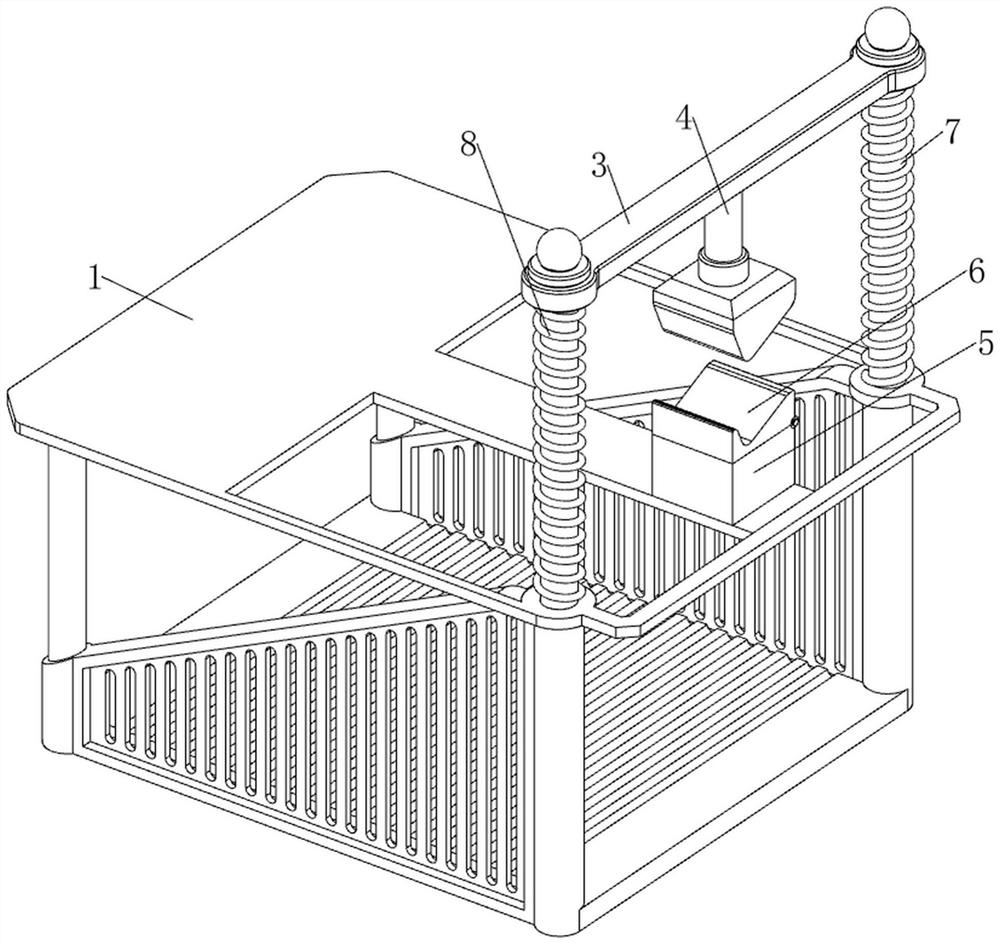

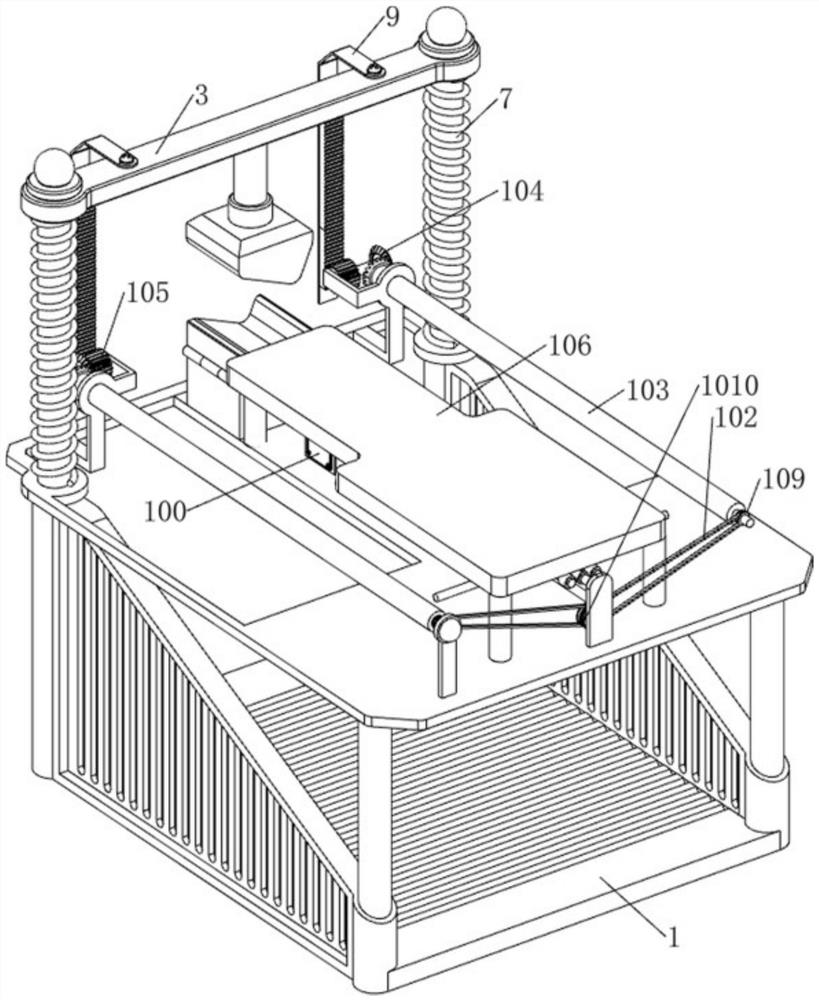

[0037] A stamping equipment for automated mechanical parts, such as Figure 1-18 As shown, it includes a base 1, a first shell 2, a first connecting rod 3, an upper mold 4, a stamping table 5, a lower mold 6, a first slide bar 7, a first spring 8, a rack 9, a transmission mechanism 10 and The push mechanism 11, the base 1 is fixedly connected with the first shell 2, the left and right sides of the rear side of the base 1 are fixedly connected with the first slide bar 7, and the top of the first slide bar 7 is jointly slidably connected with the first connecting rod 3, the first The first spring 8 is set on the sliding rod 7, the bottom of the first spring 8 is fixedly connected with the base 1, the top of the first spring 8 is fixedly connected with the first connecting rod 3, and the middle of the bottom of the first connecting rod 3 is fixedly connected with the upper mold 4. The middle of the rear side of the base 1 is fixedly connected with a stamping table 5, the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com