High-performance model predictive control algorithm for diode clamping type three-level converter

A technology of model predictive control and diode clamping, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of difficult calculation of weight coefficient values, failure to consider common mode voltage suppression, Affect the output current harmonics and other issues to achieve the effect of solving the deterioration of control performance, omitting the design of weight items, and reducing the harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, so that those skilled in the art understand the present invention, but should be clear, the present invention is not limited to the scope of specific embodiment, to those of ordinary skill in the art In other words, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

[0049] The specific implementation steps are as follows:

[0050] A high-performance model predictive control algorithm for a diode-clamped three-level converter, comprising the following steps:

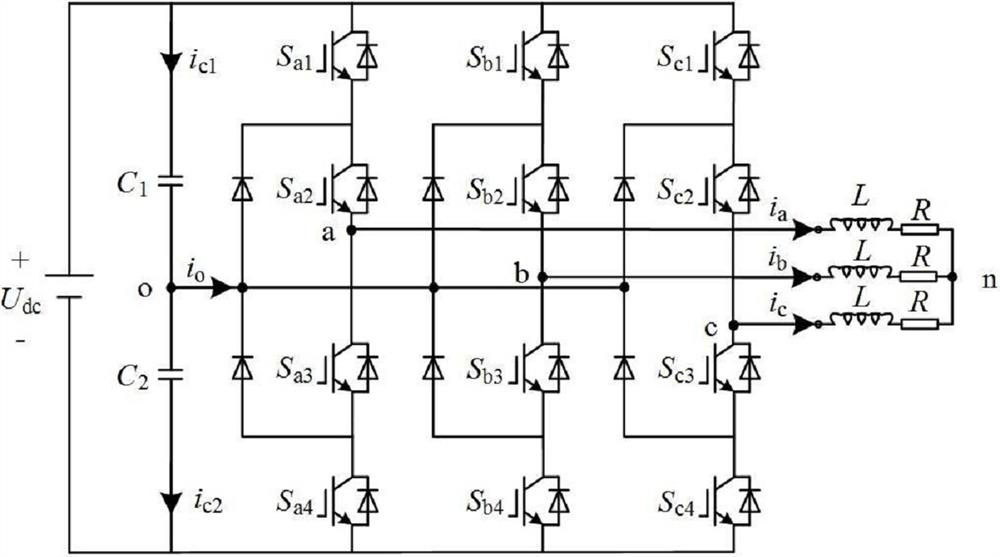

[0051] Step 1: Establish a mathematical model of a diode-clamped three-level converter. Diode-clamped three-level converter topology such as figure 1 as shown, C 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com