Remote intelligent monitoring method for clamping force of narrow lap welding machine clamp

A technology of intelligent monitoring and lap welding, applied in the direction of force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as uncontrollable pulling force, potential safety hazards, instability, etc., to improve production quality and ensure production Quality, improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

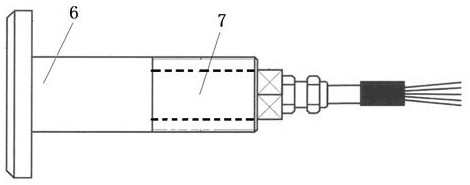

[0019] Example figure 1 As shown, the remote intelligent monitoring method for the clamping force of the narrow lap welding machine clamp of the present invention includes the following steps:

[0020] Step 1, a force sensor 1 is set in the clamping bolt of the clamp of the narrow lap welding machine, and the force sensor 1 monitors the clamping force of the clamp to clamp the strip steel through the clamping bolt during the welding process;

[0021] Step 2, collect the monitoring signal of the force sensor 1 and transmit it to the host computer 3 after passing through the signal conditioning module and the analog-to-digital conversion module 2;

[0022] Step 3. The upper computer 3 analyzes and calculates the clamping state of the clamps in the working state according to the collected monitoring signals, and sets the safety threshold of the clamping force of the clamps according to the production process of the cold-rolled galvanizing unit, and uses the analyzed and calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com