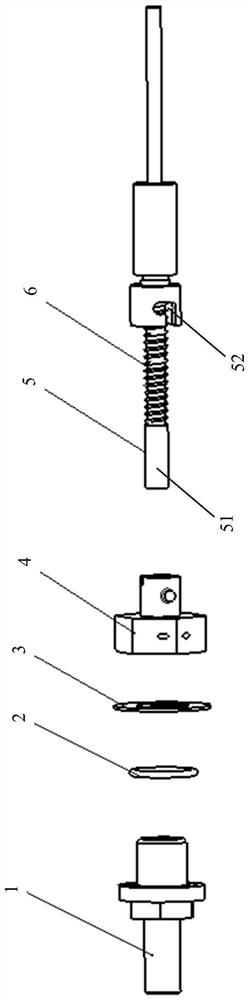

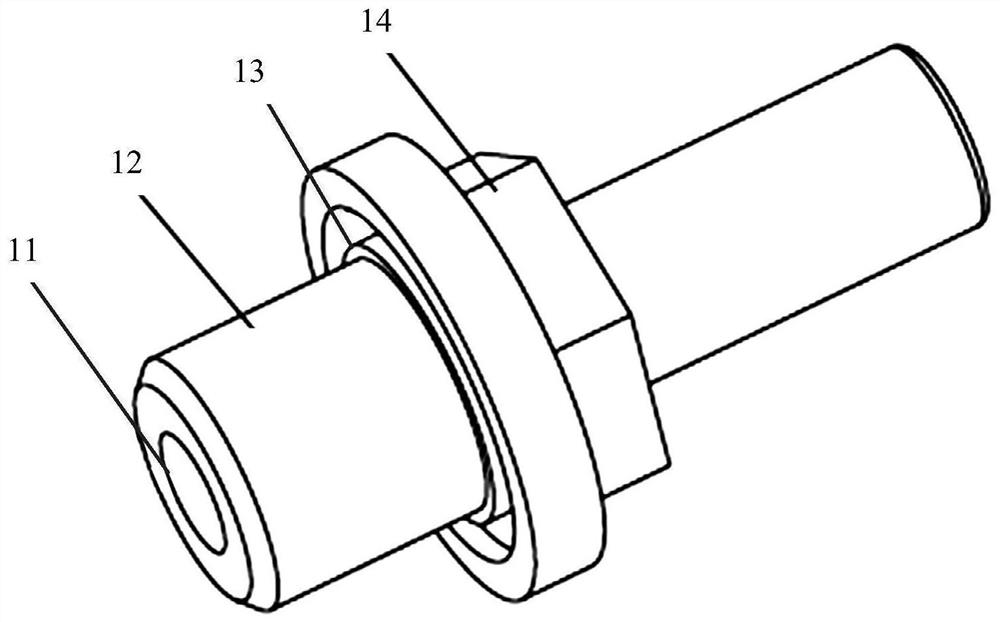

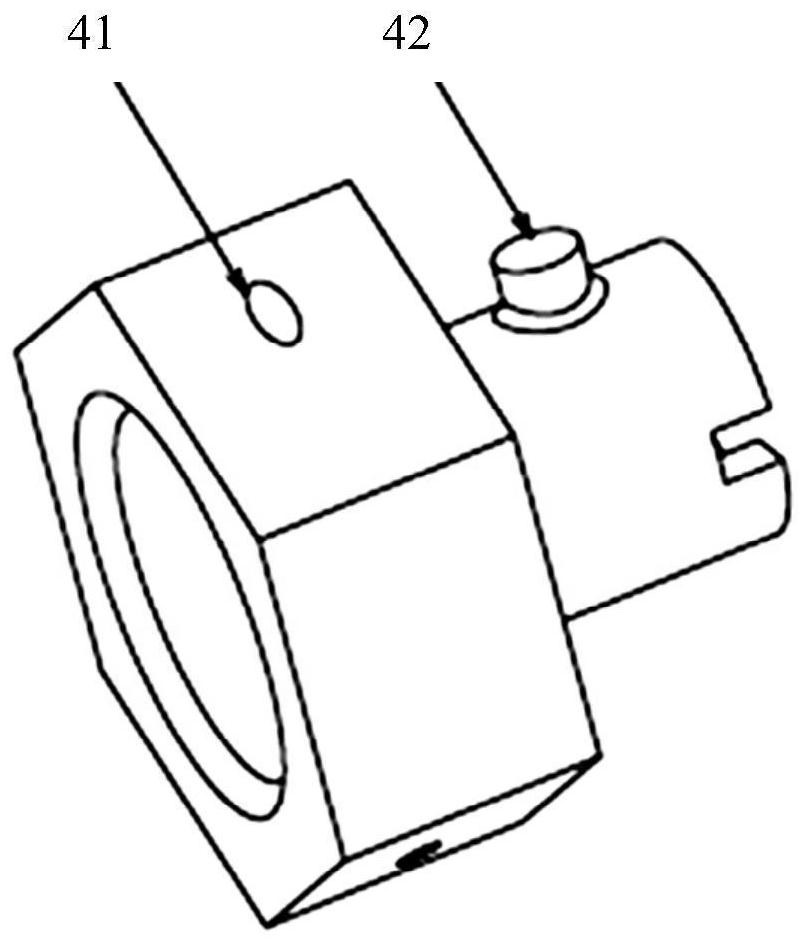

Aircraft Fuel Temperature Sensor Mounting Kit

A temperature sensor and installation component technology, applied in the aviation field, can solve the problems of many openings in the fuel tank wall, affecting the structural strength, ignition source risk, etc., to avoid electromagnetic interference, reduce the number of openings, and stabilize the output of the resistance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The specific embodiments of the present invention will be described below. It should be noted that, in the specific description of these embodiments, for the sake of brevity and conciseness, this specification may not describe all the features of the actual embodiments in detail. It should be understood that in the actual implementation process of any embodiment, just as in the process of any engineering project or design project, in order to achieve the developer's specific goals, in order to meet the system-related or business-related constraints, Often a variety of specific decisions are made, which also vary from one implementation to another. Furthermore, it will also be appreciated that while such development efforts may be complex and tedious, for those of ordinary skill in the art to which this disclosure pertains, the techniques disclosed in this disclosure will Some changes in design, manufacture or production based on the content are just conventional technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com