Vinasse volume measurement method based on depth imaging

A technology for volume measurement and distiller's grains, which is applied to measuring devices, instruments, optical devices, etc., can solve the problems affecting the batching process and the quality of distiller's grains, and achieves the effect of improving the degree of standardization and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for measuring the volume of distiller's grains based on depth imaging provided by the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

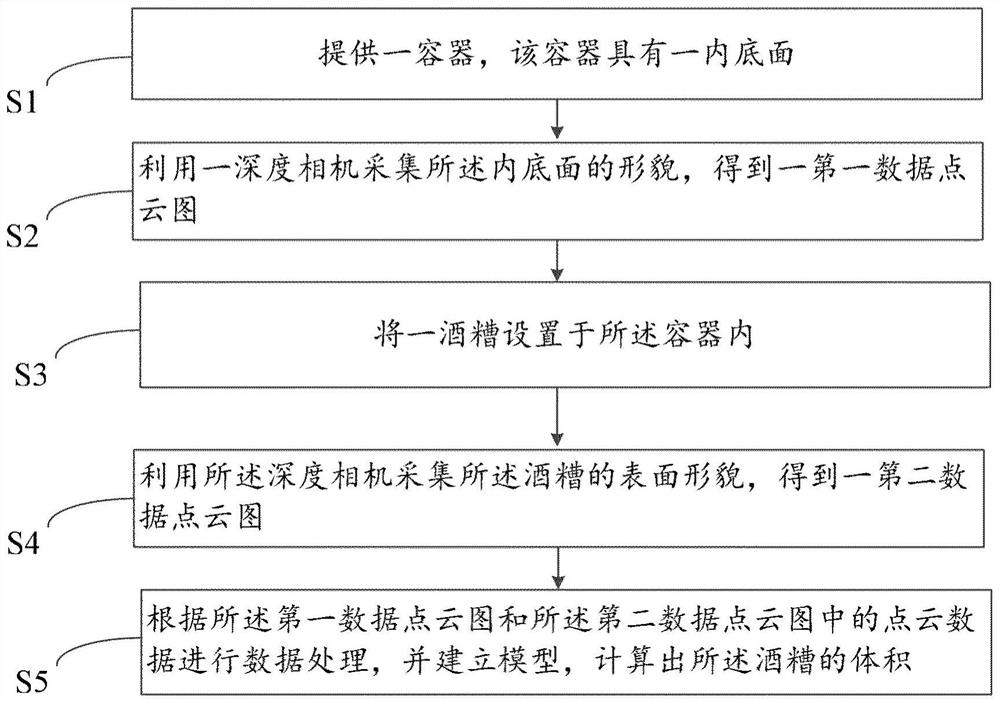

[0027] See figure 1 , the present invention provides a method for measuring the volume of distiller's grains based on depth imaging, which includes the following steps:

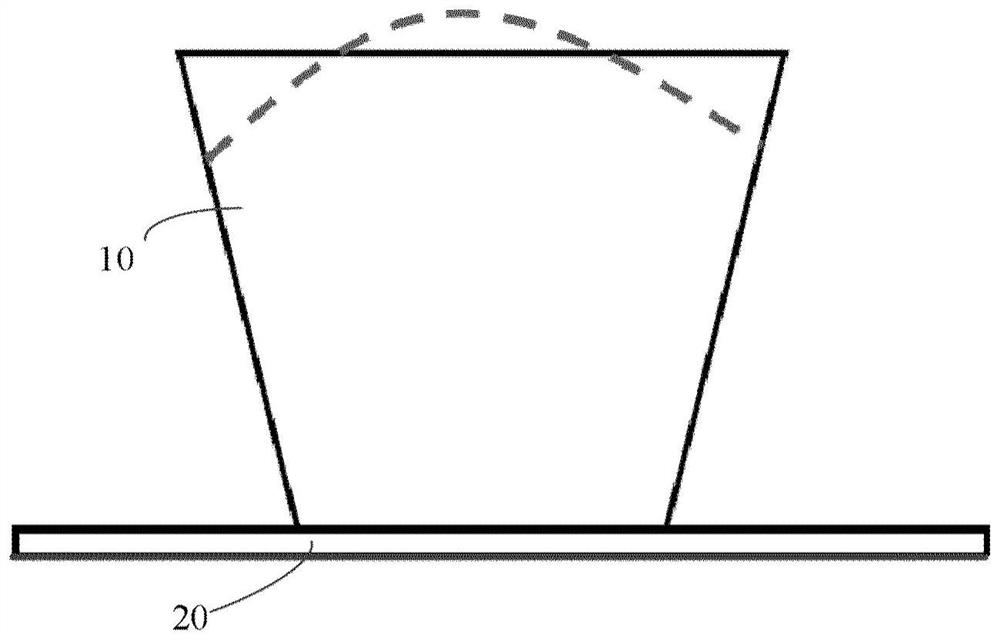

[0028] S1, providing a container, the container has an inner bottom surface;

[0029] S2. Using a depth camera to collect the topography of the inner bottom surface to obtain a first data point cloud image;

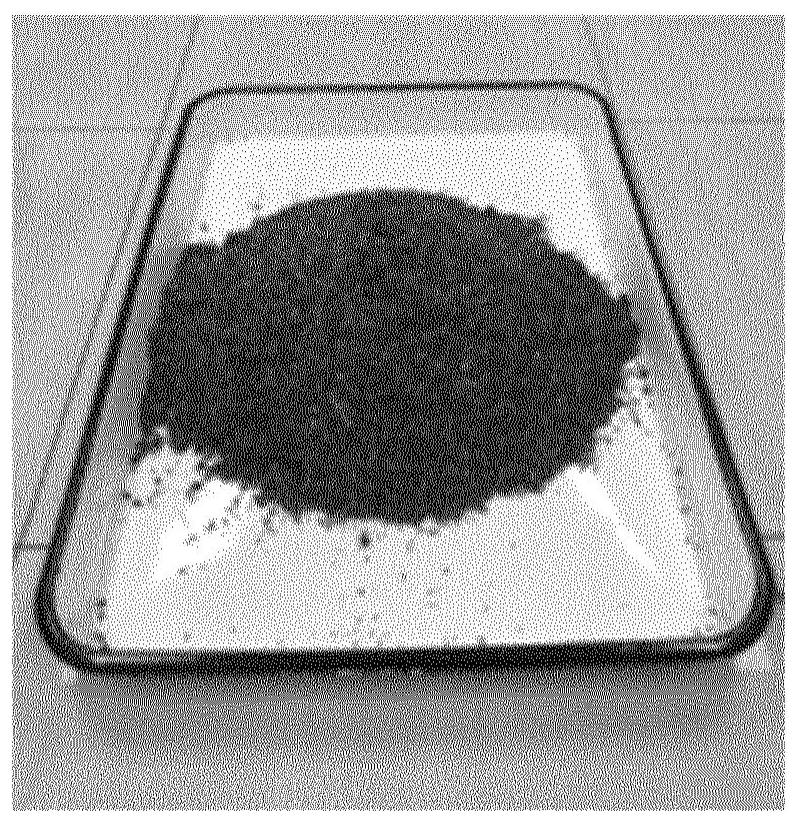

[0030] S3, disposing a distiller's grains in the container;

[0031] S4, using the depth camera to collect the surface topography of the distiller's grains to obtain a second data point cloud image; and

[0032] S5. Perform data processing according to the point cloud data in the first data point cloud image and the second data point cloud image, and establish a model to ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap