Special blow-down valve for environment-friendly sewage treatment engineering

An environmentally friendly sewage and sewage valve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of pipeline rust removal, performance degradation, and valve blockage, etc., to speed up sewage discharge, increase fluidity, Turn on the relaxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

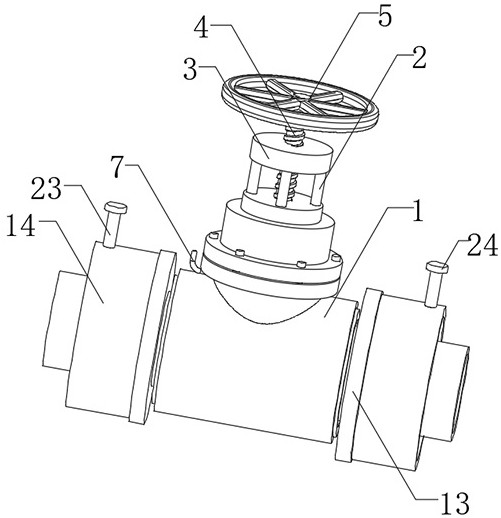

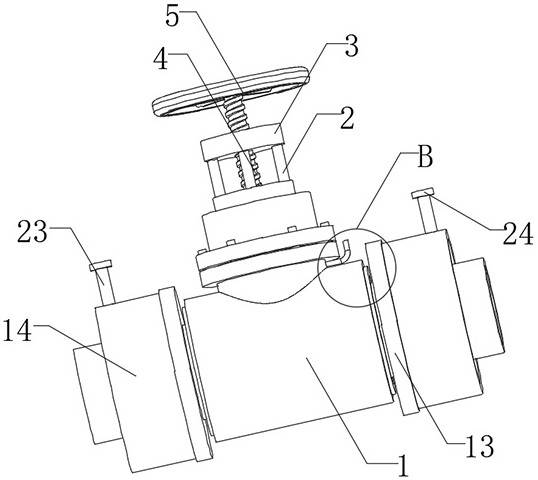

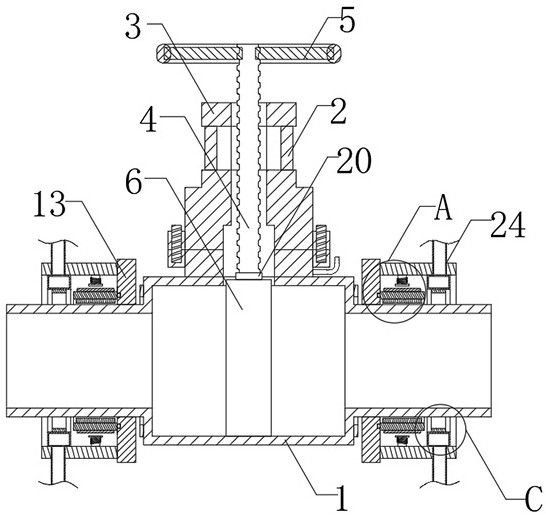

[0034] see Figure 1-Figure 7 , the present invention provides a technical solution: a sewage valve dedicated to environmental protection sewage treatment engineering, including a sewage valve body 1, the top of the sewage valve body 1 is fixedly connected with a fixed support 2 that is evenly distributed, and a fixed pillar 2 is arranged above the sewage valve body 1. Plate 3, the fixed plate 3 is fixedly connected to the top of the sewage valve body 1, the internal thread of the fixed plate 3 is connected with the screw 4, the screw 4 extends to the inside of the sewage valve body 1, and the screw 4 and the sewage valve body 1 rotate Connection, the top of the screw rod 4 is fixedly connected with a rotating handle 5, the inside of the sewage valve body 1 is provided with a valve plate 6, and the top of the valve plate 6 is fixedly connected with a connecting bearing 20, and the screw rod 4 rotates with the valve plate 6 through the connecting bearing 20 Connection, the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com