Movable spray cooling device and method for reducing near-field accumulated heat of tunnel face

A cooling device and mobile technology, applied in the direction of mobile frame, mine/tunnel ventilation, safety device, etc., can solve the problem of difficulty in effectively reducing the near-field accumulated heat of the tunnel face, affecting the life safety of workers, and inability to perform normal construction, etc. problems, to achieve the effect of improving the construction work environment, improving the cooling effect, and convenient material acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

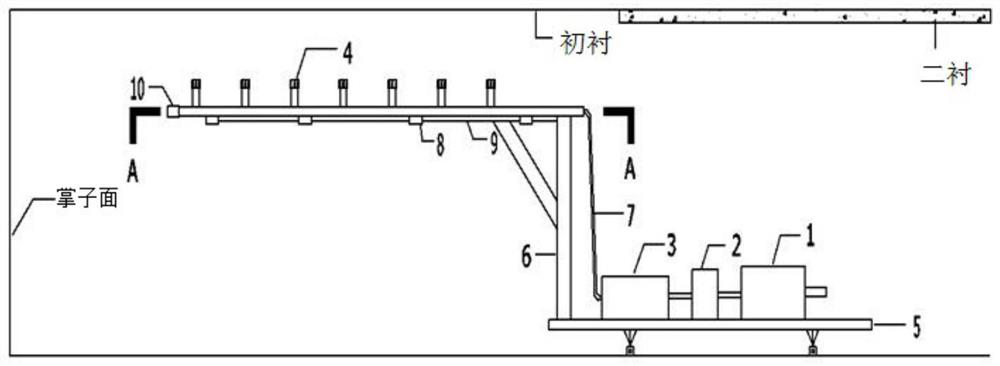

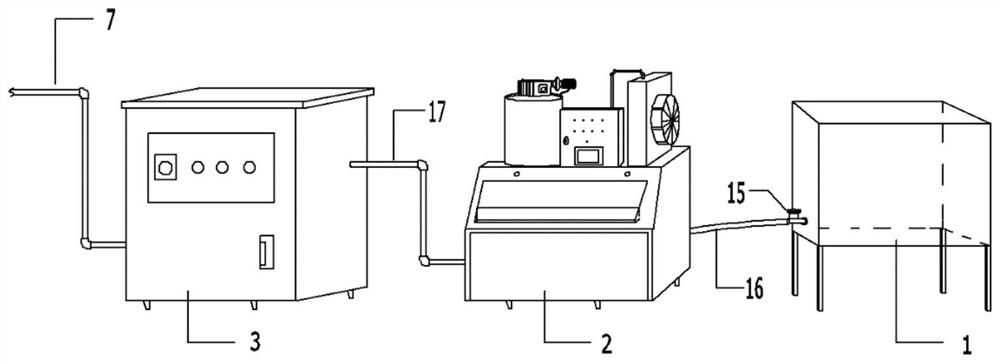

[0035] Such as figure 1 As shown, the mobile spray cooling device disclosed in this embodiment includes a water tank 1), an ice maker 2, a fog maker 3, a construction site flatbed 5 and a bracket.

[0036] The water tank 1, the ice maker 2 and the fog maker 3 are placed on the flatbed truck 5 on the construction site, and the bottom of the support is connected to the flatbed truck 5 on the construction site.

[0037] The bracket is equipped with a water-guiding high-pressure pipe network, and the water-guiding high-pressure pipe network is equipped with a plurality of atomizing nozzles 4 with water outlets facing upwards. The atomizing nozzles 4 communicate with the inside of the water-guiding high-pressure pipe network. The water in the water high-pressure pipe network is converted into an atomized state.

[0038] The storage bin 21 of the ice maker 2 has a cooling water flow channel 22 for the cooling water to pass through. The second pipeline 17 is connected to the water ...

Embodiment 2

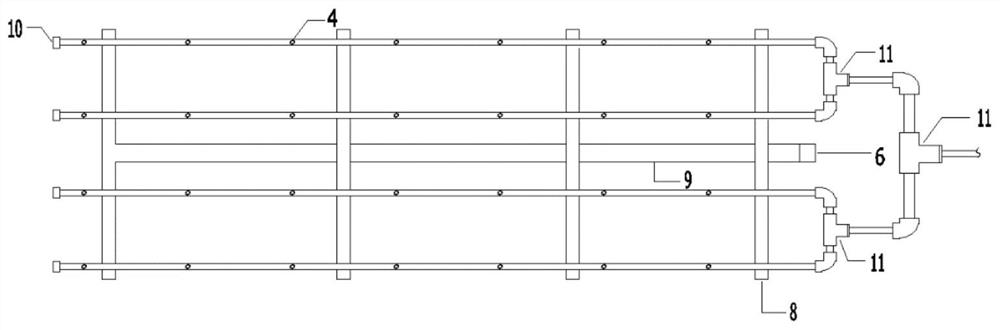

[0055] Such as figure 2 As shown, in this embodiment, the middle parts of a plurality of cross bars 8 are connected with the longitudinal bars 9 to form a horizontal frame, and one side of the longitudinal bars 9 is fixedly connected with the upper end of the vertical bar 6 .

[0056] When the diameter of the high-pressure pipeline is reduced, a different-diameter joint should be used; a bushing should not be used at the elbow of the pipeline; when a bushing is required, a three-way connection should be used; a pipe with a nominal diameter greater than 50 mm should not use a live joint.

[0057] After the water pipe is laid through the fog machine 3, it is divided into four roads by the three-way 11 branch joint, and the end of each road is blocked with a terminal plug 10. The longitudinal length of each high-pressure pipe is 100-120 meters. The distance between the nozzles is 4 meters, and the distance between the nozzles is set to 1 meter on each road.

[0058] Straighten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com