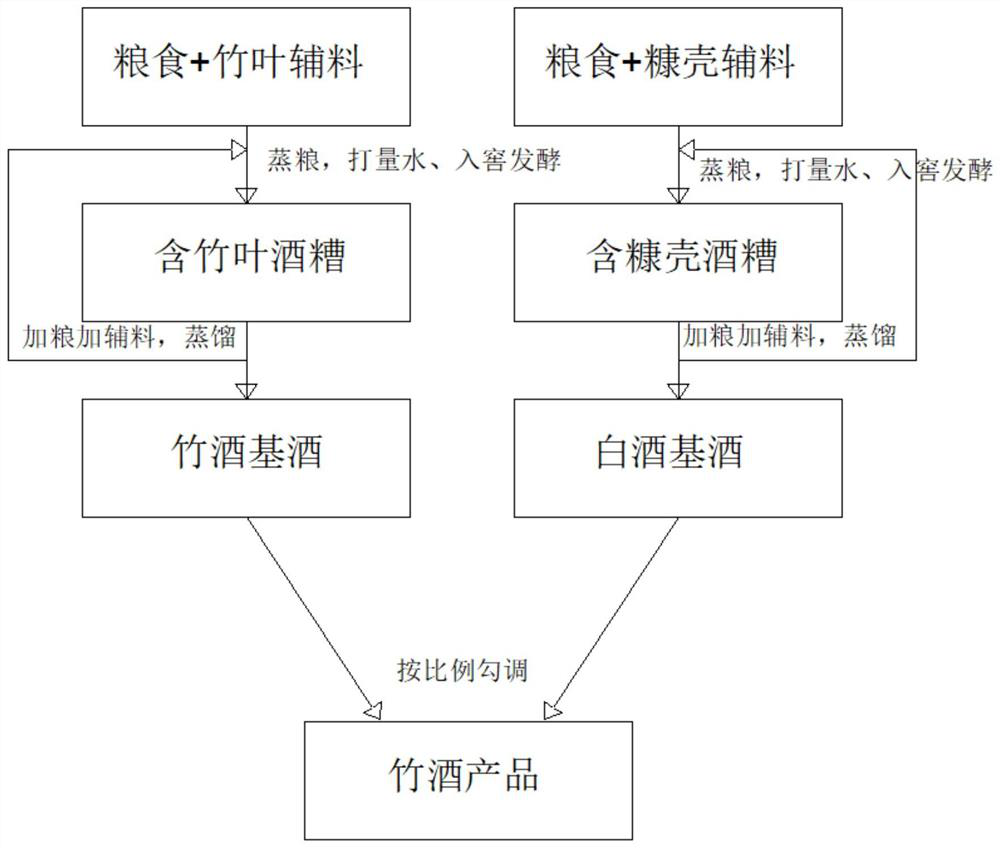

Process for preparing bamboo wine by adopting two-stage fermentation method

A fermentation method and bamboo wine technology, applied in the field of winemaking, can solve the problems of heavy research work, difficult to control the ratio of bamboo material and bran shell, etc., and achieve the effects of rich flavor, clear wine color and appearance, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of concrete brewing example, comprises following operations:

[0028] Step 1, preparation of bamboo leaves: wash and dry fresh bitter bamboo leaves or crush them after drying, with a size of 5 mm to 10 mm;

[0029] Step 2, raw material preparation: sorghum (36%), rice (22%), glutinous rice (18%), wheat (16%), corn (8%) are mixed and pulverized in proportion;

[0030] Step 3, steaming grain: add a certain proportion of auxiliary materials to the mixed grain with grain: auxiliary material 1:0.2, wherein the auxiliary materials are 100% chaff or 100% bitter bamboo leaves, (the chaff is steamed for 30 minutes, steamed and used immediately) , mix well, steam the grains in retorts for 1 hour, then take them out and spread them evenly;

[0031] Step 4. Measure the water and put it into the cellar for fermentation: pour hot water at 80-100°C according to the ratio of 1:1 of the grain quality. When the temperature reaches 28-32°C, sprinkl...

Embodiment 2

[0037] The present embodiment provides a kind of concrete brewing example, comprises following operations:

[0038] Step 1, preparation of bamboo leaves: wash and dry fresh Mianzhu bamboo leaves or crush them after drying, with a size of 5 mm to 10 mm;

[0039] Step 2, raw material preparation: sorghum (36%), rice (22%), glutinous rice (18%), wheat (16%), corn (8%) are mixed and pulverized in proportion;

[0040] Step 3, steaming grain: add a certain proportion of auxiliary materials to the mixed grain with grain: auxiliary material 1:0.18, wherein the auxiliary materials are 100% chaff or 100% Mianzhu bamboo leaves, (the chaff is steamed for 30 minutes, steamed and used immediately) , mix well, steam the grains in retorts for 1 hour, then take them out and spread them evenly;

[0041] Step 4. Measure the water and put it into the cellar for fermentation: pour hot water at 80-100°C according to the ratio of 1:1 of the grain quality. When the temperature reaches 28-32°C, spri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com