Preparation method of asphalt concrete

A technology of asphalt concrete and modified asphalt, which is applied in the field of asphalt concrete, can solve the problems that the compressive capacity of asphalt concrete cannot be applied for a long time, the compressive strength of asphalt concrete is limited, and the compressive strength of asphalt concrete is optimized, so as to improve the efficiency of laying work, Reduce the number of repeated repairs and increase the effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

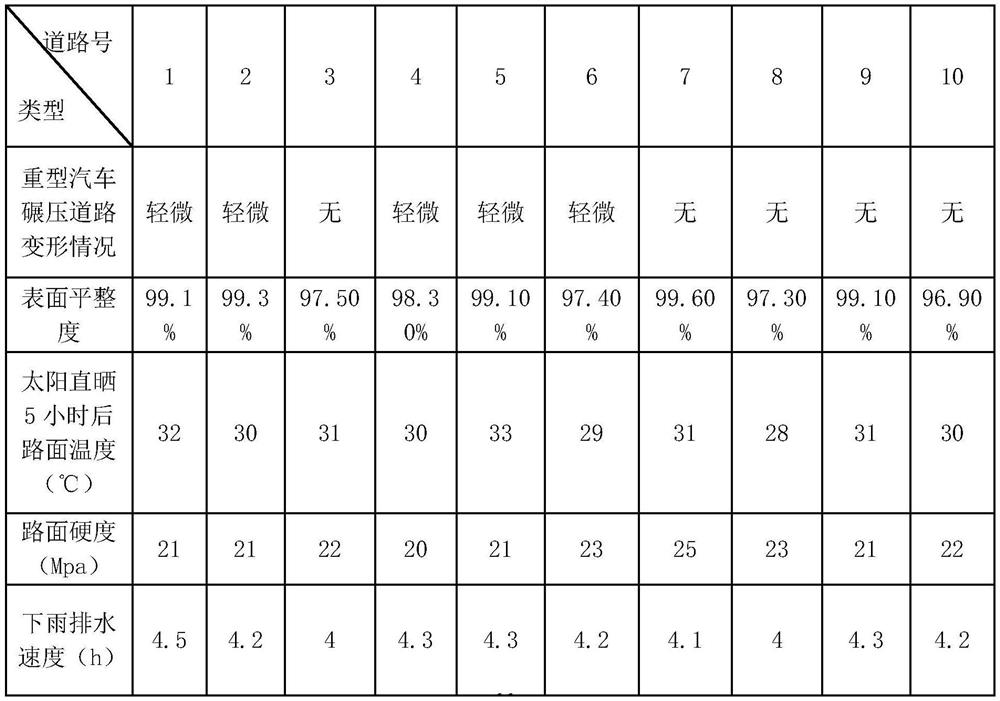

Examples

Embodiment 1

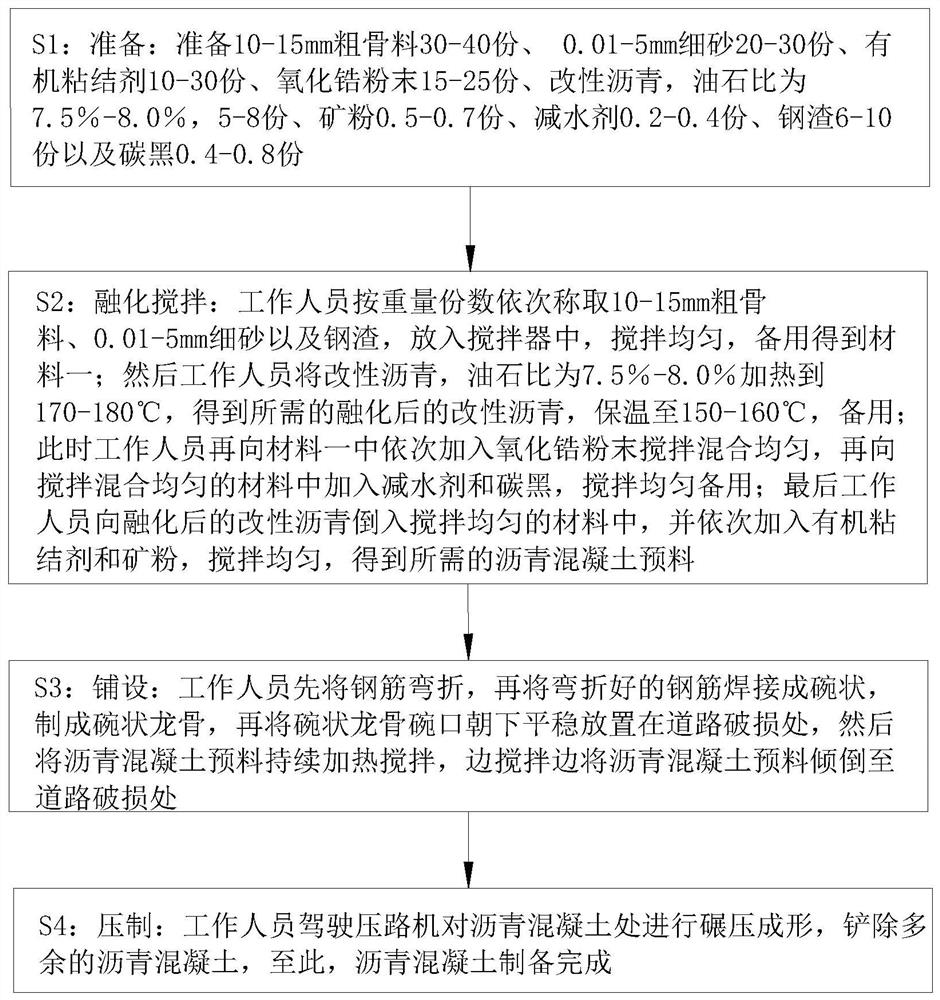

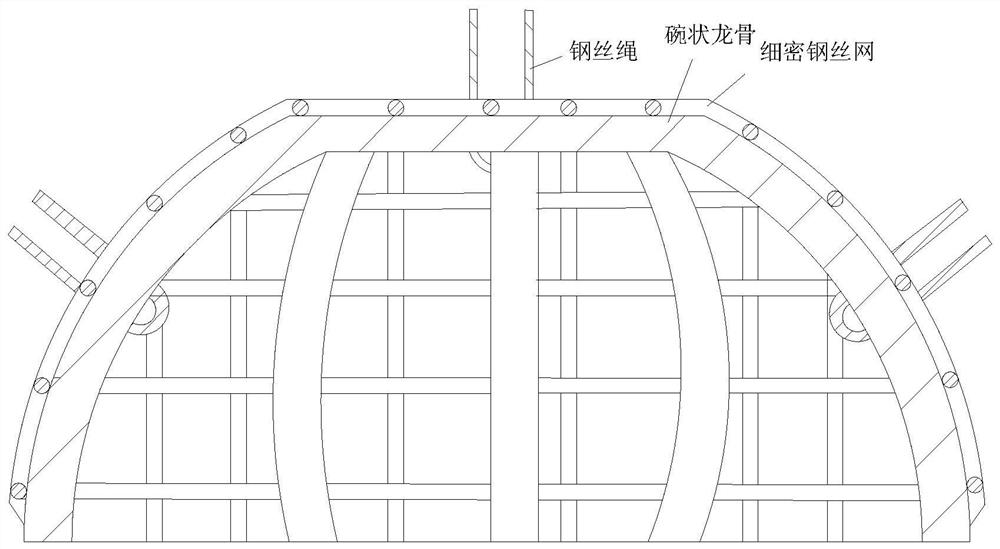

[0045] The asphalt concrete preparation method is as follows:

[0046] S1: Preparation: prepare 30 parts of 10mm coarse aggregate, 20 parts of 0.01mm fine sand, 10 parts of organic binder, 15 parts of zirconia powder, 5 parts of modified asphalt oil stone ratio of 7.5%, 0.5 part of mineral powder, minus 0.2 parts of water agent, 6 parts of steel slag and 0.4 parts of carbon black;

[0047] S2: Melting and stirring: the staff weighs 10mm coarse aggregate, 0.01mm fine sand and steel slag in sequence by weight, puts them into the mixer, stirs them evenly, and obtains material 1 as a spare; then the staff mixes the modified asphalt, oil stone ratio 7.5% and heated to 170°C to obtain the required melted modified asphalt, kept warm to 150°C, and set aside; at this time, the staff then added zirconia powder to material 1 and stirred and mixed evenly, and then added to the evenly mixed asphalt Add water reducing agent and carbon black to the material, stir well and set aside; finally...

Embodiment 2

[0053] The asphalt concrete preparation method is as follows:

[0054] S1: Preparation: Prepare 35 parts of 13mm coarse aggregate, 35 parts of 2.5mm fine sand, 20 parts of organic binder, 20 parts of zirconia powder, 7 parts of modified asphalt oil stone ratio, 0.6 part of mineral powder, 0.3 parts of water agent, 8 parts of steel slag and 0.6 parts of carbon black;

[0055] S2: Melting and stirring: the staff weighs 13mm coarse aggregate, 2.5mm fine sand and steel slag in sequence by weight, puts them into the mixer, stirs them evenly, and obtains material 1 as a spare; then the staff mixes the modified asphalt, asphalt 8% and heated to 175°C to obtain the required melted modified asphalt, kept warm to 155°C, and set aside; at this time, the staff then added zirconia powder to material 1 and stirred and mixed evenly, and then added to the evenly mixed asphalt Add water reducing agent and carbon black to the material, stir well and set aside; finally, the staff pours the melt...

Embodiment 3

[0061] The asphalt concrete preparation method is as follows:

[0062] S1: Preparation: Prepare 40 parts of 15mm coarse aggregate, 30 parts of 5mm fine sand, 30 parts of organic binder, 25 parts of zirconia powder, 8 parts of modified asphalt oil stone ratio, 0.7 part of mineral powder, water reducing 0.4 parts of agent, 10 parts of steel slag and 0.8 parts of carbon black;

[0063] S2: Melting and stirring: the staff weighs 15mm coarse aggregate, 3mm fine sand and steel slag in sequence by weight, puts them into the mixer, stirs them evenly, and obtains material 1 as a spare; 8.5% is heated to 180°C to obtain the required melted modified asphalt, which is kept warm to 160°C for standby; at this time, the staff adds zirconia powder to material 1 and mixes them evenly, and then pours them into the evenly mixed material Add water reducing agent and carbon black to the mixture, stir well and set aside; finally, the staff pours the melted modified asphalt into the well-stirred ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com