Preparation method, product and application of Te nanomaterial with controllable morphology

A nano-material and morphology technology, applied in the field of preparation of Te materials, can solve problems such as poor controllability, and achieve the effects of low production cost, easy availability of raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

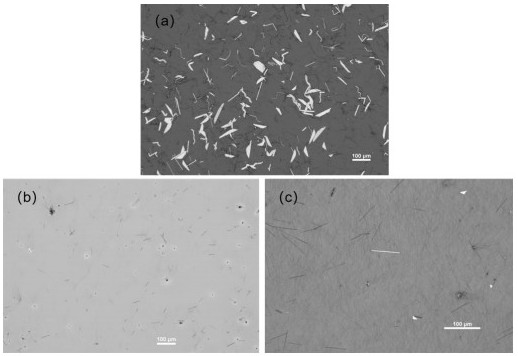

Embodiment 1

[0037] Step 1, weigh 0.0462g Na 2 TeO 3 and 1.5g of PVP with an average molecular weight of 8000, the Na 2 TeO 3 Add 16mL of deionized water, stir evenly, then add PVP, stir again to obtain a transparent gel-like mixed solution A;

[0038] Step 2, add 1.66mL of ammonia water and 0.840mL of hydrazine monohydrate to the mixed solution A, stir well, transfer to the lining of a 25mL reaction kettle, seal and put it in a blast drying oven for 14 hours at 180°C;

[0039] Step 3. After the hydrothermal reaction in step 2 is completed, immediately cool it with running water at 15°C, add 10 mL of deionized water to the obtained solution, set the centrifugation speed at 5000r / min and the centrifugation time for 10min, centrifuge twice, and separate And the precipitate was washed to obtain Te nanomaterials with controllable morphology. Finally, 15ml of deionized water is added to the precipitate for dispersion. (The purpose of dispersion: we are to obtain Te solution, which is spin-c...

Embodiment 2

[0042] Step 1, weigh 0.0462g Na 2 TeO 3 and 1.5g of PVP with an average molecular weight of 360000, the Na 2 TeO 3 Add 16mL of deionized water, stir evenly, then add PVP, stir again to obtain a transparent gel-like mixed solution A;

[0043] Step 2, add 1.66mL of ammonia water and 0.840mL of hydrazine monohydrate to the mixed solution A, stir well, transfer to the lining of a 25mL reaction kettle, seal and put it in a blast drying oven for 14 hours at 180°C;

[0044] Step 3: After the hydrothermal reaction in step 2 is completed, immediately cool it with running water at 15°C, add 10 mL of deionized water to the obtained solution, set the centrifugation speed at 5000r / min, centrifugation time at 10min, and centrifuge twice. The precipitate was separated and washed to obtain Te nanomaterials with controllable morphology. Finally, 15ml of deionized water is added to the precipitate for dispersion. (The purpose of dispersion: we are to obtain Te solution, which is spin-coated...

Embodiment 3

[0047] Step 1, weigh 0.0462g Na 2 TeO 3 and 1.5g of PVP with an average molecular weight of 1,300,000, the Na 2 TeO 3 Add 16mL of deionized water, stir evenly, then add PVP, stir again to obtain a transparent gel-like mixed solution A;

[0048] Step 2, add 1.66mL of ammonia water and 0.840mL of hydrazine monohydrate to the mixed solution A, stir well, transfer to the lining of a 25mL reaction kettle, seal and put it in a blast drying oven for 14 hours at 180°C;

[0049] Step 3: After the hydrothermal reaction in step 2 is completed, immediately cool it with running water at 15°C, add 10 mL of deionized water to the obtained solution, set the centrifugation speed at 5000r / min, centrifugation time at 10min, and centrifuge twice. The precipitate was separated and washed to obtain Te nanomaterials with controllable morphology. Finally, 15ml of deionized water is added to the precipitate for dispersion. (The purpose of dispersion: we are to obtain Te solution, which is spin-coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com