Improved method for screen printing two-dimensional code platemaking

A screen printing and two-dimensional code technology, applied in printing, printing plate preparation, printing devices, etc., can solve the problems of unrecognizable, cost-increased, and code-scanning equipment, and achieve the effect of improving the generalization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention is an improved method for screen printing two-dimensional code plate making, which is characterized in that it comprises the following steps:

[0022] (1). After the two-dimensional code graphic is black and white reversed, the plate is made, so that the blank area and the binary data "0" area in the two-dimensional code graphic can see through the white ink;

[0023] Specifically, the two-dimensional code graphics are black and white reversed before plate making, so that the ink-permeable area becomes the white area before the two-dimensional code is reversed, and when printed on black products, it is still white ink corresponding to the white area of the two-dimensional code , and the black area of the two-dimensional code borrows the black product itself, the two-dimensional code is displayed normally, and the computer reads 1 / 0 without confusion;

[0024] (2). Cooperate with the color of the black product itself to complement the border patrol area...

Embodiment 2

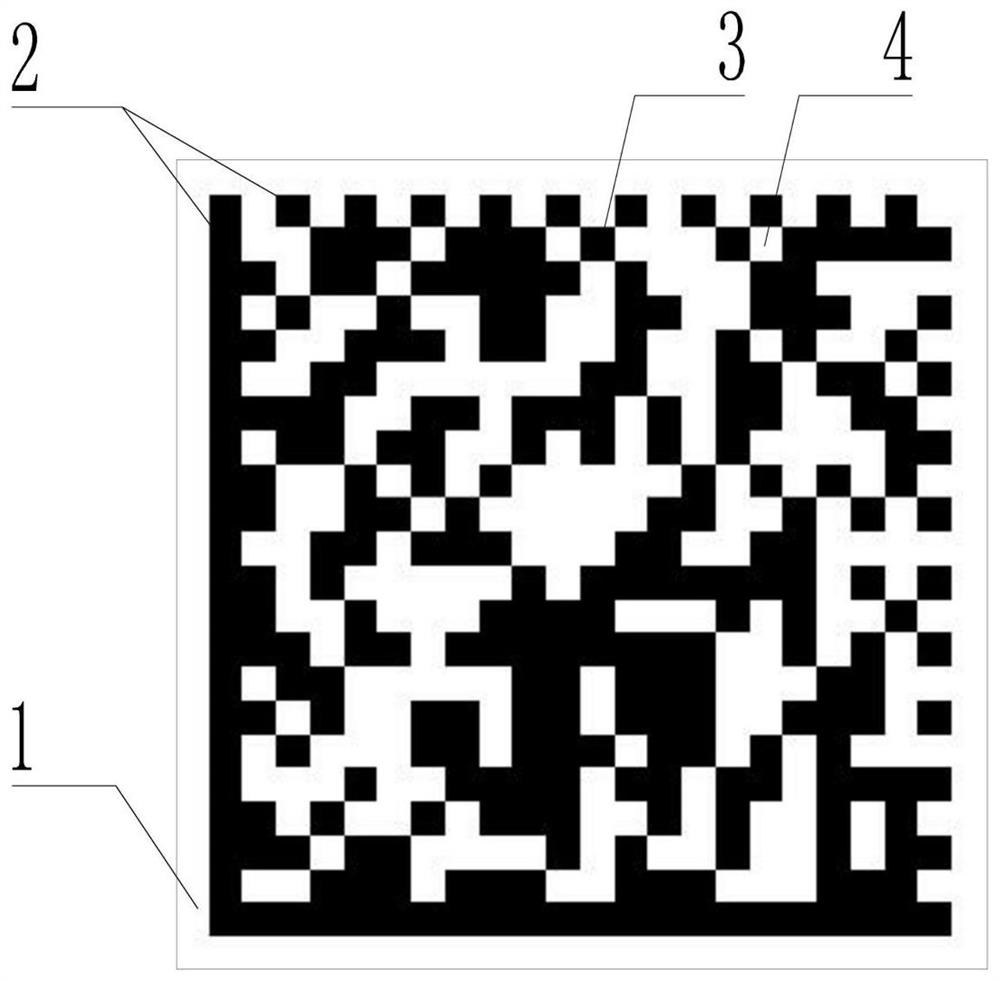

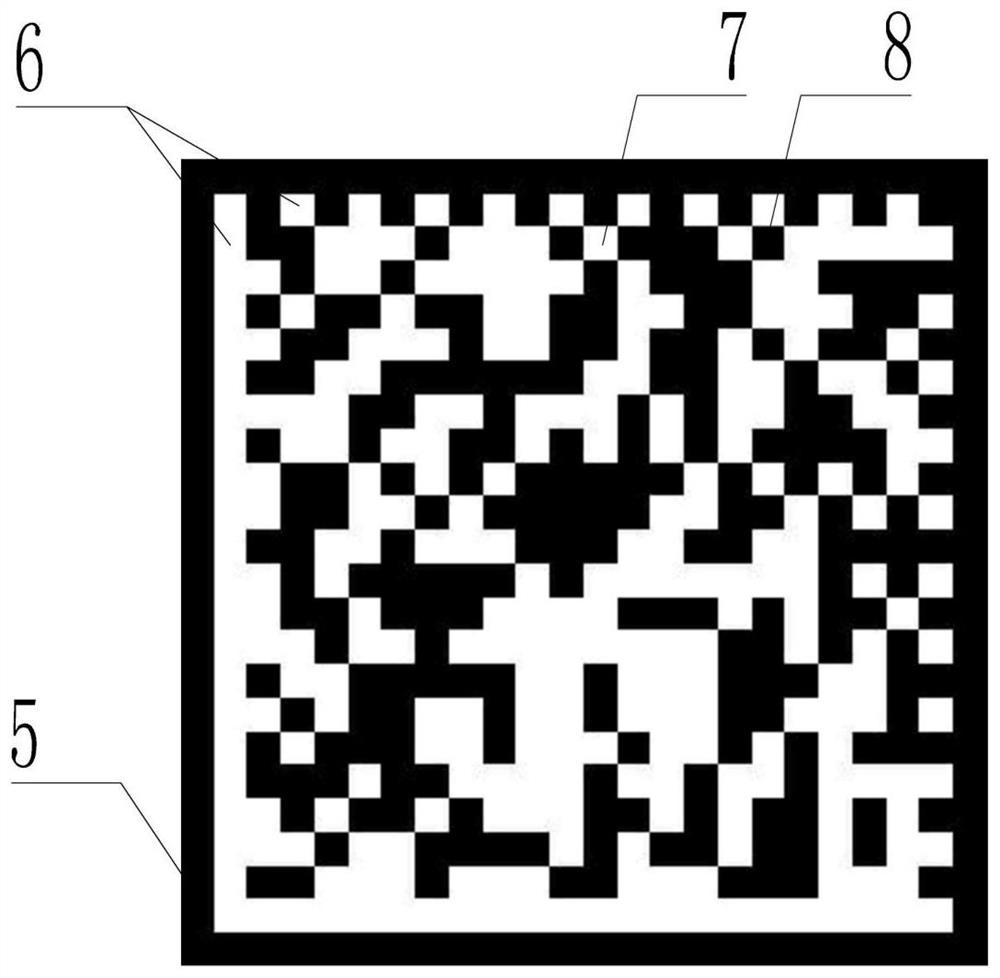

[0027] refer to Figure 1-Figure 2 , the present invention is an improved method for screen printing two-dimensional code plate making, by using the improved method to produce figure 1 The original conventional DataMatrix QR code graphics shown in the figure are black and white and reversed, and after processing, it is figure 2 shown. use figure 2 The two-dimensional code graphic shown in the screen printing plate is made according to the production principle of the screen printing plate: the blank area 5 after inversion, the black part of the patrol area 6 after inversion, and the binary data "0" area 8 after inversion Can pass through the ink.

[0028] After the printing plate is made, use white ink to print on the surface of the black product. The white ink will pass through the blank area 5 after inversion, the black part of the border area 6 after inversion, and the binary data "0" area 8 after inversion. The ink printing area corresponds to figure 1 The blank area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com