Intelligent-based automatic cutting machine capable of achieving online monitoring

A cutting machine, automatic technology, applied in the direction of automatic control devices, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of not having the function of cutting angle adjustment, and achieve the effect of easy online observation and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

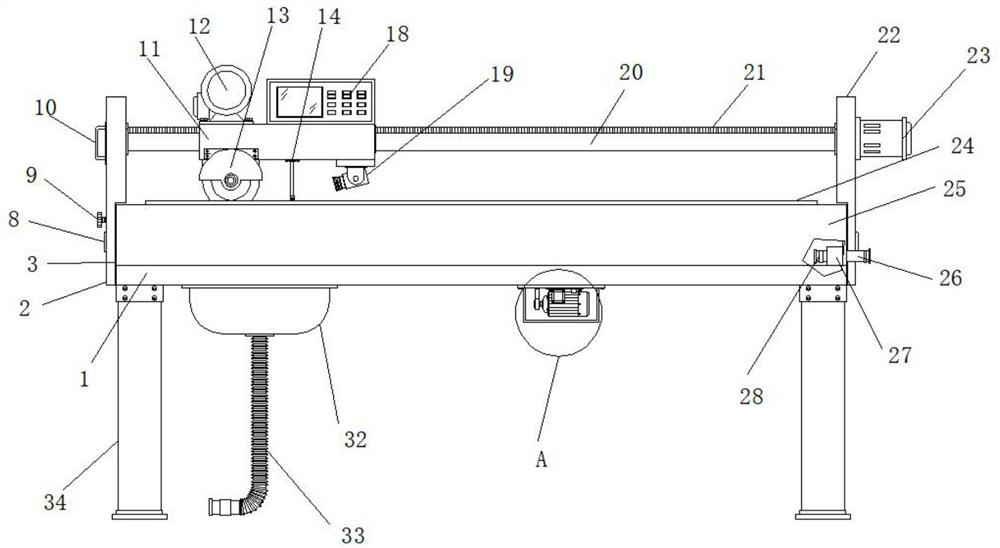

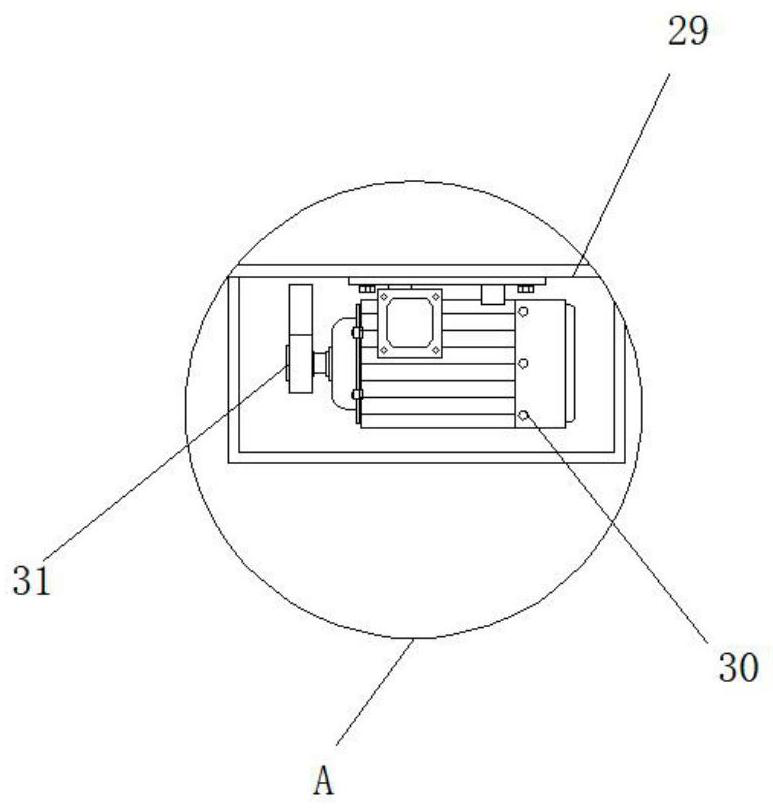

[0028] Example 1: See Figure 1-6 , a kind of automatic cutting machine based on intelligence that can be monitored online, including a frame body 1, the top of the frame body 1 is fixedly connected with a coaming plate 25, and the two sides of the bottom end of the frame body 1 are respectively equipped with supporting legs 34, and the sides of the coaming plate 25 One side is provided with the left side plate 2, the other side of the enclosure 25 is provided with the right side plate 22, the top of the frame body 1 is provided with the base 11, one side of the bottom end of the base 11 is provided with a camera 19, the left side plate 2 Between one side of the right side plate 22 and the laterally fixedly connected slide shaft 20, between the left side plate 2 and one side of the right side plate 22 is horizontally movably connected with the threaded shaft 21, and one side of the right side plate 22 is installed with the first A servo motor 23, the output end of the first se...

Embodiment 2

[0032] Embodiment 2: The inside of the fixed seat 3 is provided with a plurality of sets of limit holes 6, one side of the fixed seat 3 is etched with a scale pattern 7, one side of the left side plate 2 is horizontally inserted with a limit knob 9, and the left side plate 2- The interior of the side is provided with an observation window 35;

[0033] The shape and size of one side of the limit knob 9 matches the shape and size of the limit hole 6, the external thread of the limit knob 9 matches the internal thread of the limit hole 6, and the position of the observation window 35 corresponds to the position of the scale pattern 7. It is convenient to observe in time and choose a suitable angle for fixing;

[0034] Specifically, such as Figure 5 and Image 6As shown, the user can pass through the rotation angle through the observation window 35. When reaching a suitable angle, tighten the limit knob 9, and the limit knob 9 snaps into the limit hole 6 to complete the angle f...

Embodiment 3

[0035] Embodiment 3: The base plate 14 is fixedly connected to the middle position of the bottom end of the base 11, and two sets of mounting bolts 15 are inserted vertically inside the bottom end of the base plate 14. The bottom end of the plate 16 is glued with a soft brush 17;

[0036] The installation bolts 15 are distributed symmetrically about the vertical center line of the base plate 14, and the installation is more stable;

[0037] Specifically, such as figure 1 and figure 2 As shown, in the cutting process, as the first servo motor 23 drives the threaded shaft 21 to rotate, the base 11 moves left and right along the sliding shaft 20, and the driving motor 12 drives the cutting disc 13 to cut the material, and the dust generated by cutting The stain is blocked by the dust shielding plate 16, and along with the left and right movement of the base 11, the soft brush 17 cleans the dust and impurities on the cutting edge in time, which is convenient for the online obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com