Infrasonic wave repairing machine based on big data

An infrasonic wave and big data technology, applied in the field of infrasonic wave repairing machines, can solve problems such as poor adjustment, improper pass design, pass wear, etc., and achieve the effect of increasing work efficiency, increasing effective time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

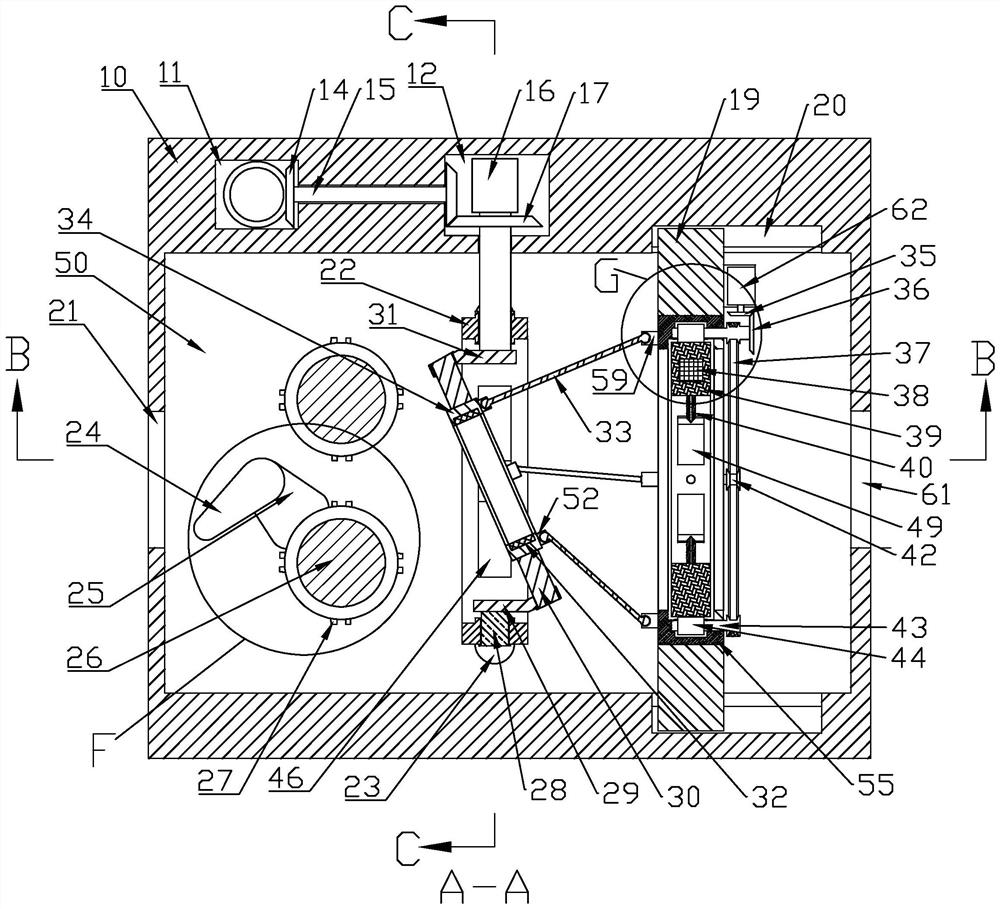

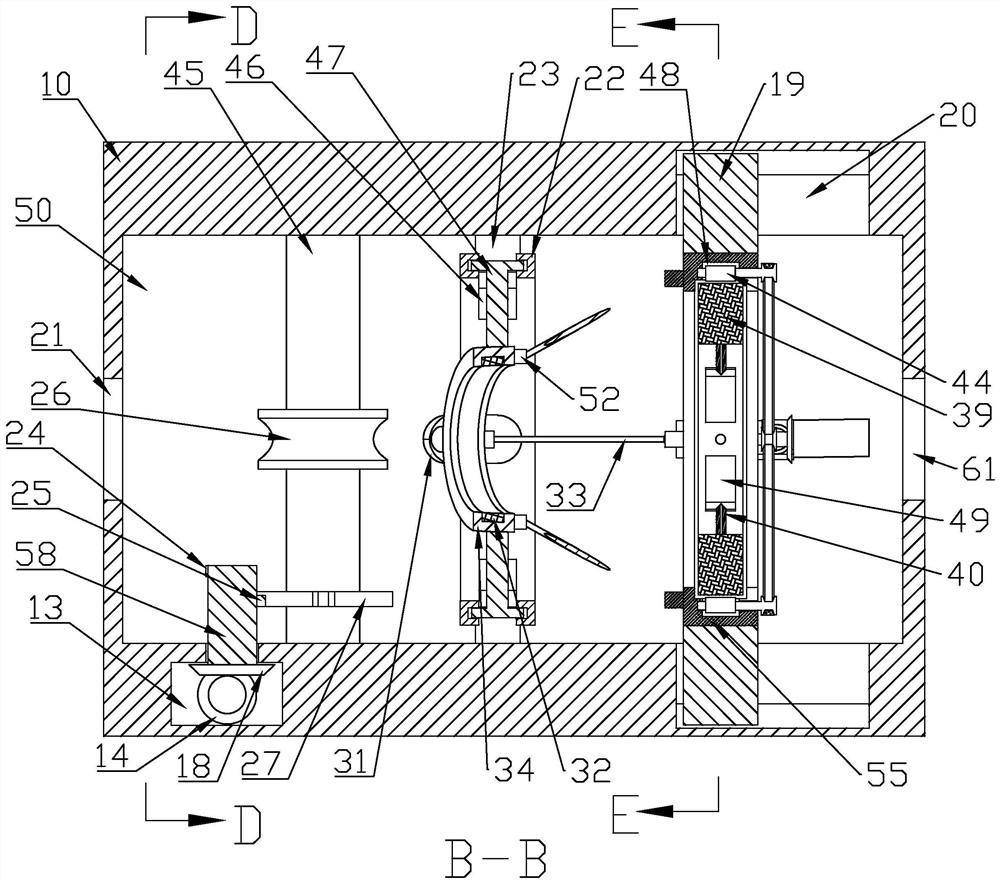

[0026] Such as figure 1 As shown, an infrasonic repair machine based on big data includes a housing 10, which is characterized in that an upper left chamber 11 is provided on the upper left side of the housing 10, a main chamber 12 is provided on the upper side of the housing 10, and a lower left chamber 12 is provided on the upper left side of the housing 10. A lower chamber 13 is provided on the side, a control center 53 is provided on the lower right side of the housing 10, a steel inlet 21 is provided on the left side wall of the housing 10, a steel outlet 61 is provided on the right side wall of the housing 10, and the housing 10 Universal rotating shaft 15 is arranged in rotation in 10, and cavity 50 is arranged in h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com