Die plate groove punching machine for chip machining

A template groove and stamping machine technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of inability to perform continuous stamping, inability to complete automatic unloading and loading, slow stamping speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

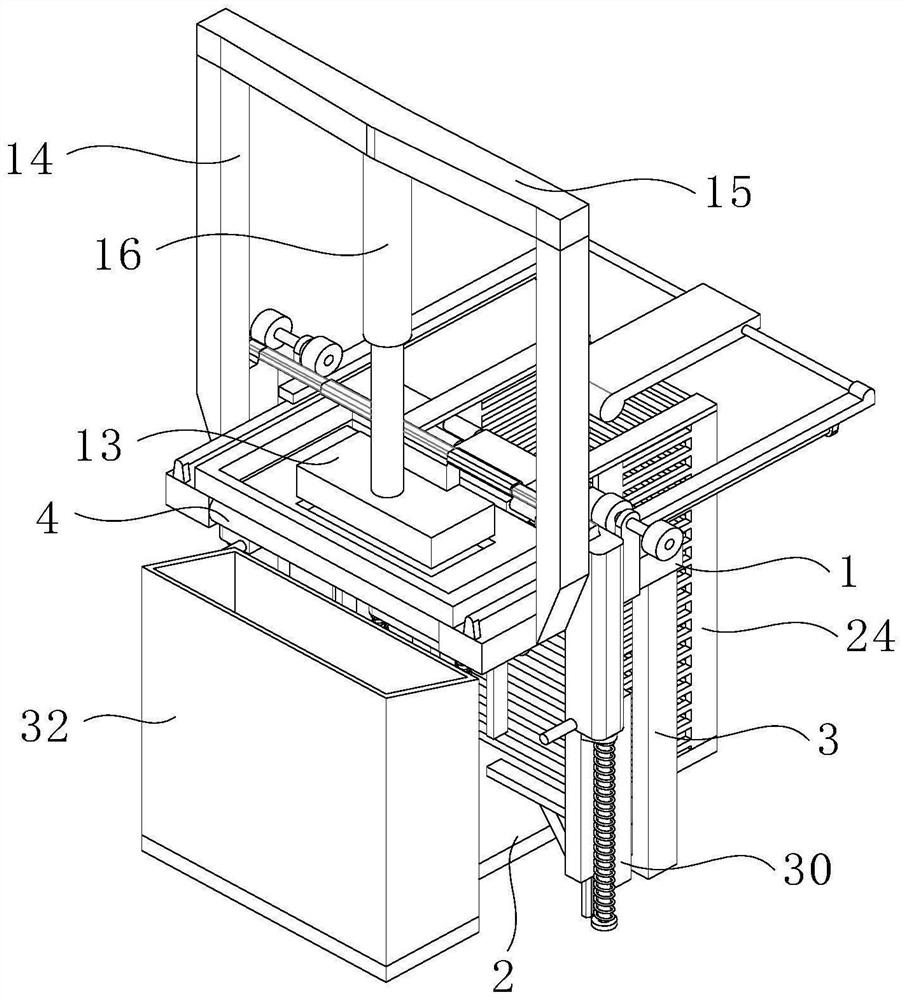

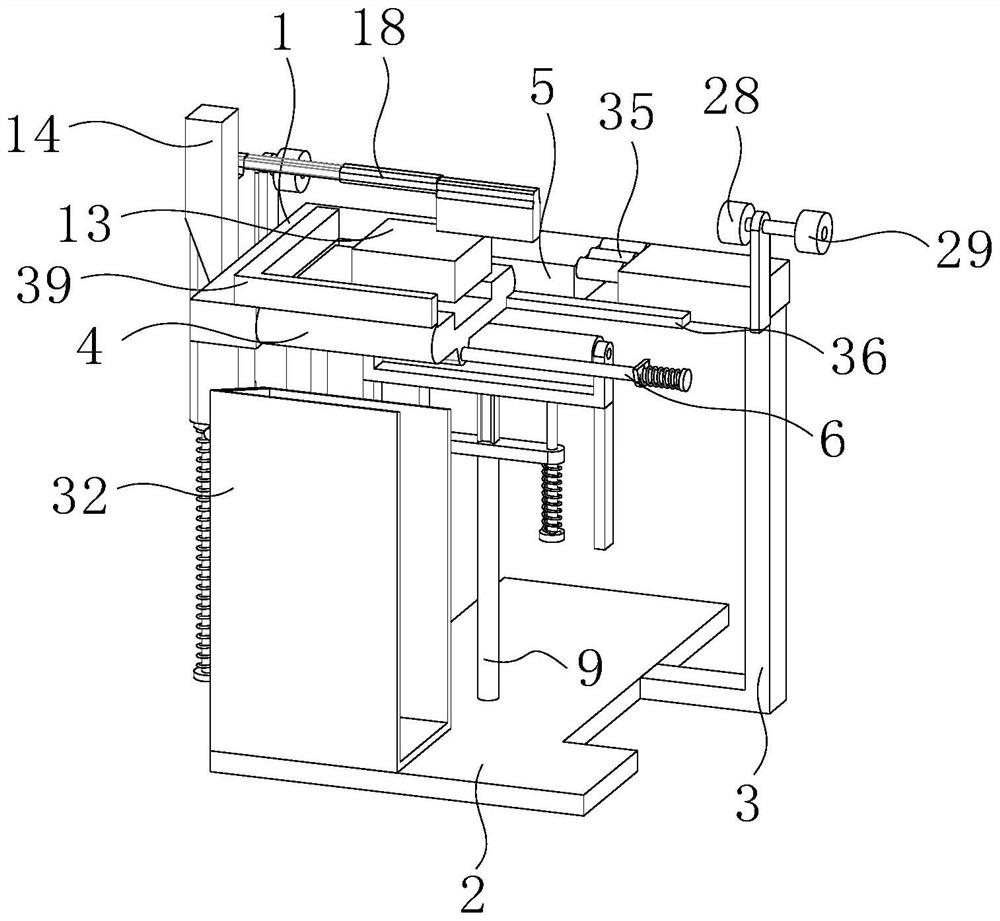

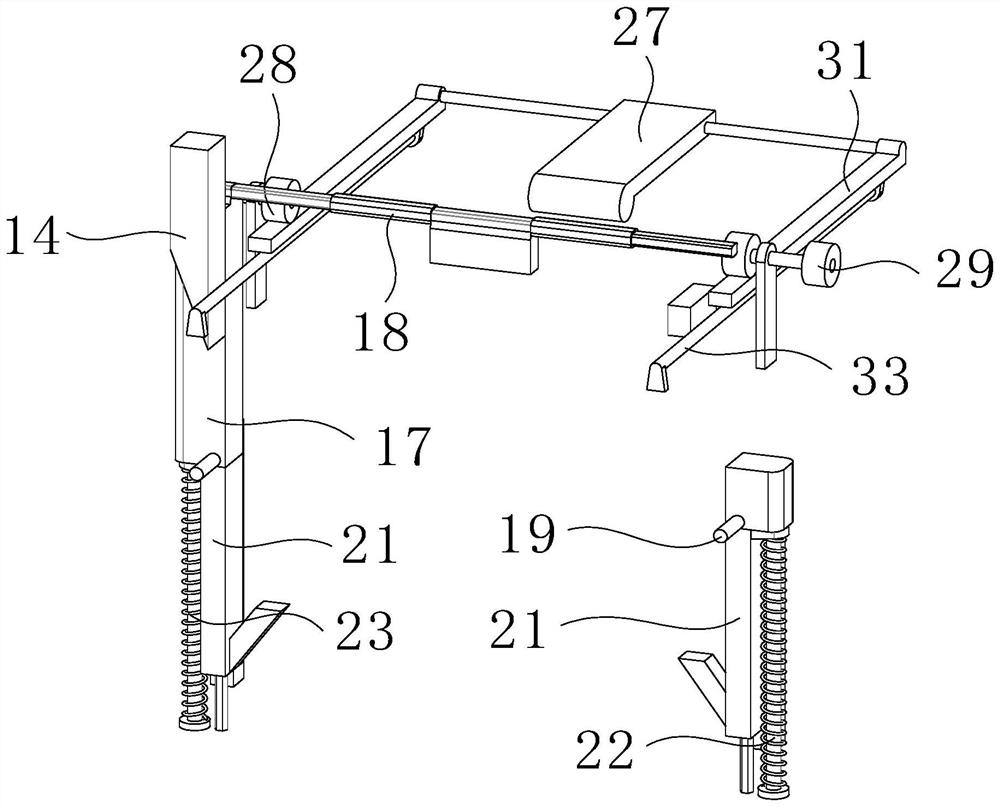

[0024] Such as Figure 1-5 As shown, a template groove stamping machine for chip processing includes a workbench 1 and a support platform 2, the workbench 1 is located above the support platform 2, and the workbench 1 and the support platform 2 are fixedly connected by two support frames 3. The upper surface of the table 1 is provided with a through hole 5, and the inside of the through hole 5 is provided with a shaping block 4, the bottom surface of the workbench 1 is elastically hinged with a support shaft 6, and the bottom surface of the shaping block 4 is fixedly sleeved on the outer surface of the support shaft 6, The support shaft 6 is positioned in front of the central axis of the shaping block 4, and the upper surface of the shaping block 4 is lower than the upper surface of the workbench 1, so that the material is positioned in the through hole 5, and the upper surface of the workbench 1 is fixedly connected with a positioning frame 39 for positioning. The frame 39 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com