Space clamp clamping mechanism

A clamping mechanism and clamping mechanism technology, applied in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problem that the clamp cannot be quickly positioned and clamped, and achieve the effect of reducing vibration, preventing rotation and facilitating fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

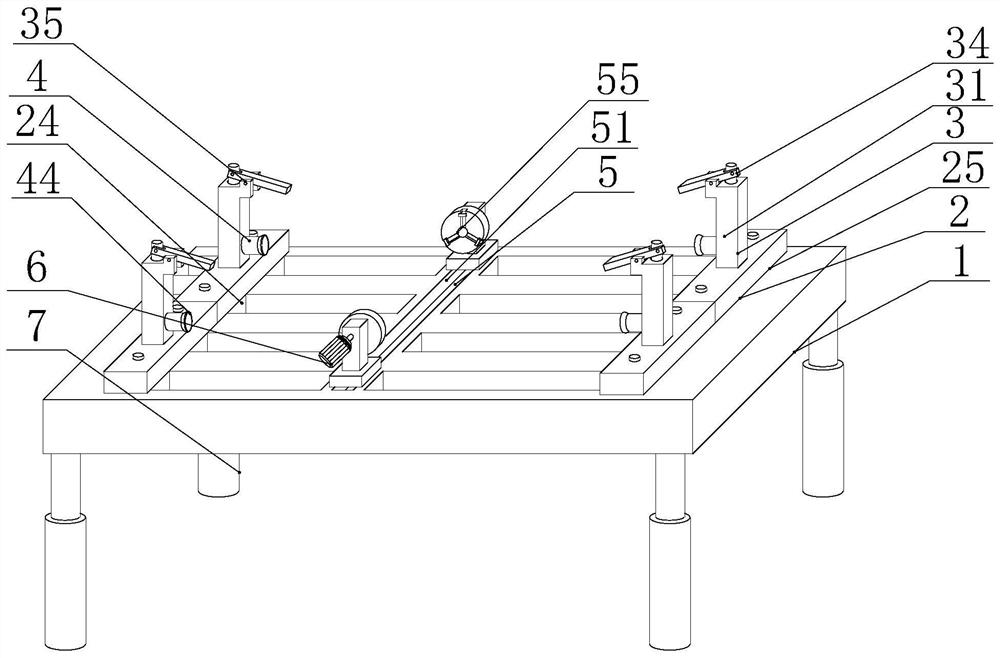

[0029] see figure 1 , a space fixture clamping mechanism of the present invention, including a working plate 1, a moving mechanism 2 is arranged on the top of the working plate 1, and the moving mechanism 2 drives the first movable block 23 and the second movable block 24 to move, so as to facilitate the clamping of parts At both ends, the top of the moving mechanism 2 is provided with a top limit mechanism 3, and the top position of the parts is limited by using the top limit mechanism 3. The positioning mechanism 4 limits the bottom position of the parts, and the four corners of the bottom of the working board 1 are fixedly connected with the support columns 7, which is convenient for the fixing and stability of the working board 1.

[0030] Existing fixtures can only clamp specific parts, but cannot achieve three-dimensional clamping, restrict each end of the parts, and prevent parts from moving. By using top clamping, lateral clamping at both ends and vertical clamping at ...

Embodiment 2

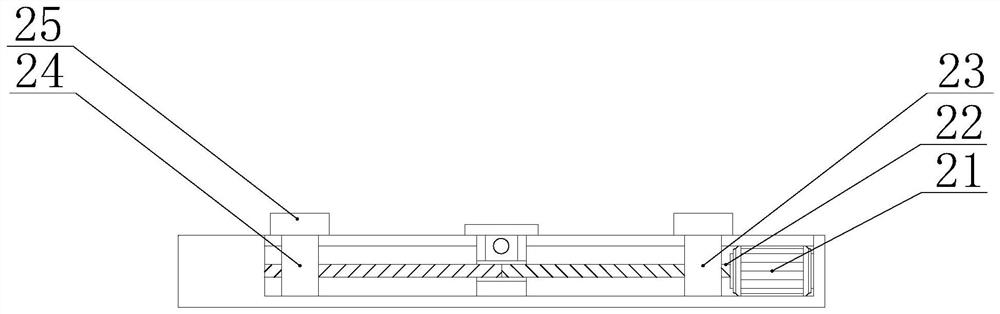

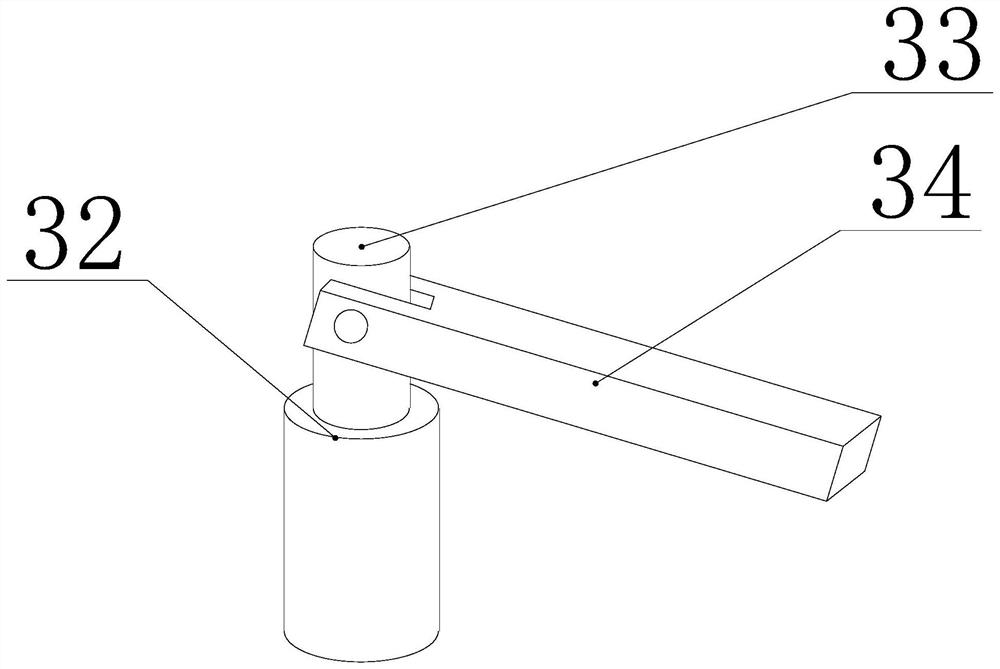

[0033] see Figure 2-4 , in order to quickly move the top limit mechanism 3 and the bottom limit mechanism 4, instead of manually clamping and fixing the parts, it is convenient for the fast fixing and limit of the parts. The moving mechanism 2 includes a first stepping motor 21, a first stepping motor 21 Fixedly connected to one end of the inner cavity of the working plate 1, the output end of the first stepping motor 21 is fixedly connected to a bidirectional threaded rod 22, and the bidirectional threaded rod 22 is provided with threads in opposite directions from the middle to both ends, and the bidirectional threaded rod 22 is close to the first step One end of the motor 21 is screwed with the first movable block 23, and the two-way threaded rod 22 is screwed with the second movable block 24 away from the first stepper motor 21. The first movable block 23 and the second movable block 24 are symmetrical to each other, so that The stepping motor 21 drives the first movable ...

Embodiment 3

[0038] see Figure 5 and Image 6 , in order to facilitate the clamping of the other two ends of the parts, the parts are completely fixed, and the parts are prevented from moving in any direction. There are two second hydraulic rods 52 that are symmetrically connected to each other, and the output end of the second hydraulic rod 52 is fixedly connected with an output rod 53, and a first pull block 54 and a second pull block 56 pass through the output rod 53, so as to facilitate the first Two hydraulic rods 52 drive the first pull block 54 and the second pull block 56 to move, and one end of the first pull block 54 is rotatably connected with a handle, and the handle passes through the end of the first pull block 54 and is threadedly connected with a three-jaw chuck 55, which is convenient for clamping and fixing on the part, preventing it from moving.

[0039] In this embodiment, in order to prevent the first pulling block 54 and the second pulling block 56 from detaching f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com