Spinning device and spinning method

A technology of processing device and small diameter part, which is applied in the direction of engine components, cylinders, mechanical equipment, etc., and can solve problems such as strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

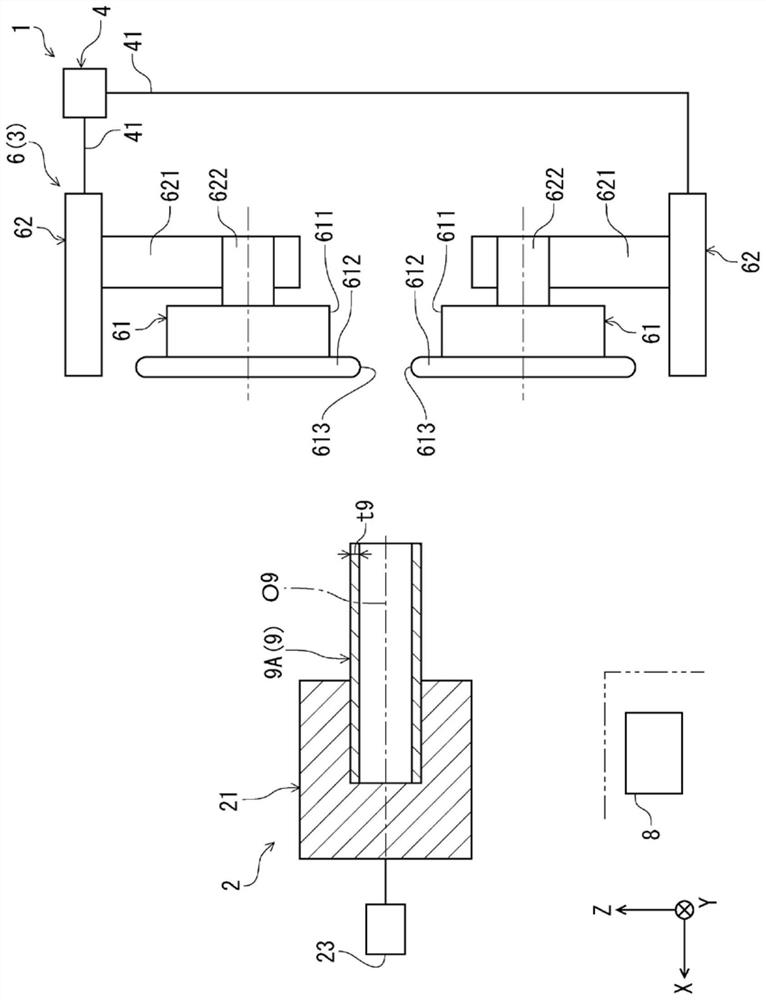

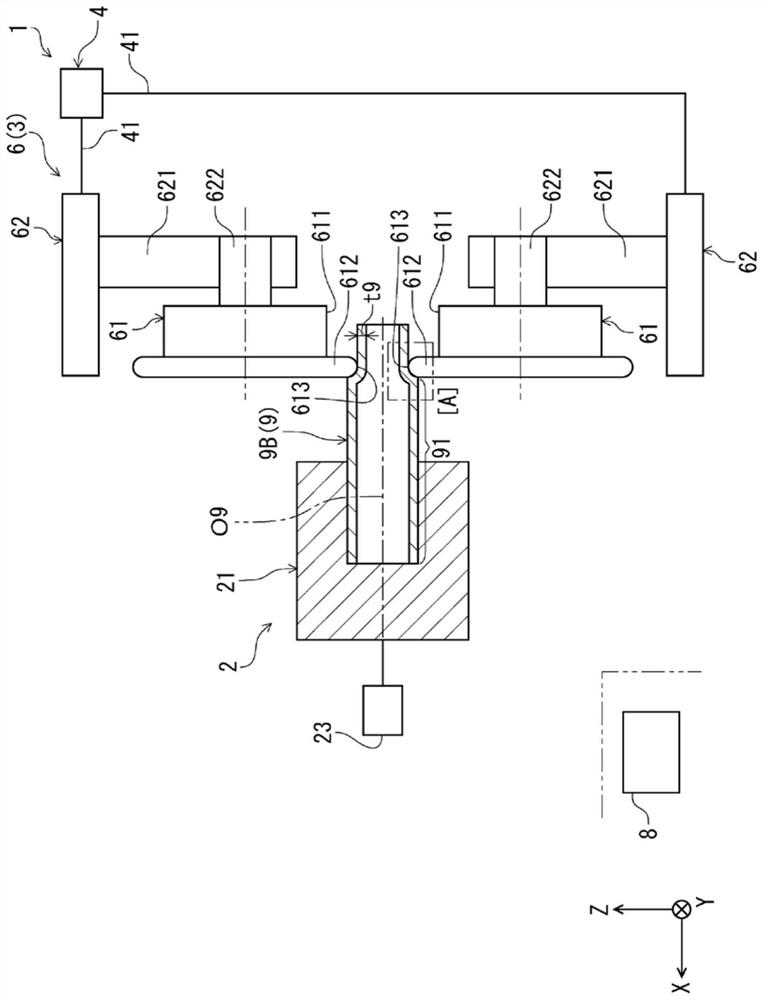

[0029] Below, refer to Figure 1 to Figure 8 A first embodiment of the spinning device and spinning method of the present invention will be described. In addition, in the following, for convenience of description, three axes orthogonal to each other are respectively set as an X axis, a Y axis, and a Z axis. As an example, the XY plane including the X axis and the Y axis is a horizontal plane, and the Z axis is a vertical axis. and, sometimes Figure 1 to Figure 6 middle( Figure 9 and Figure 10 The upper side is called "upper (or upper)" and the lower side is called "lower (or lower)".

[0030] like Figure 1 ~ Figure 4 As shown, the spinning machine 1 includes a rotation support unit 2 , a processing unit 3 , a first moving mechanism unit 4 , and a second moving mechanism unit 5 . The spinning apparatus 1 can form a base material 9 to obtain a molded product 9C from the base material 9 . Also, the molded product 9C is used, for example, as a shaft.

[0031] and, if ...

no. 2 Embodiment approach >

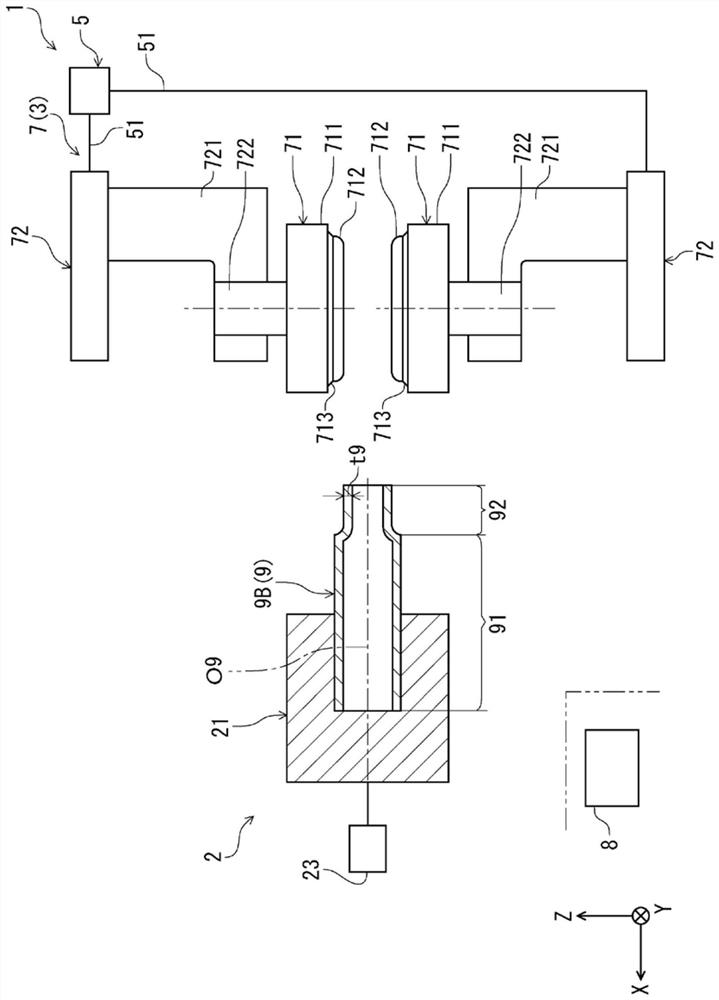

[0086] Below, refer to Figure 9 and Figure 10 The second embodiment of the spinning device and spinning method of the present invention will be described, but the description will focus on the differences from the above-mentioned embodiment, and the description of the same configuration will be omitted.

[0087] This embodiment is the same as the above-mentioned 1st Embodiment except the structure of the rotation support part 2 being different.

[0088] In this embodiment, the rotation support part 2 can be switched between the first connection state connected to the first molding part 6 and the second connection state connected to the second molding part 7 by a switching mechanism (not shown).

[0089] Moreover, in the first connection state, such as Figure 9 As shown, the rotation support part 2 is capable of rotating the first molding part 6 around the base material 9 (central axis O9 ) with respect to the base material 9 in a state in which the base material 9 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com