Measuring device and method for rapidly measuring rotor shaft sleeve

A technology for measuring devices and rotor shafts, applied in measuring devices, instruments, etc., can solve the problem of not being able to measure the shape and position tolerances of two precision bearing holes at the same time, so as to improve measurement accuracy and efficiency, facilitate measurement, and have many measurement features Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

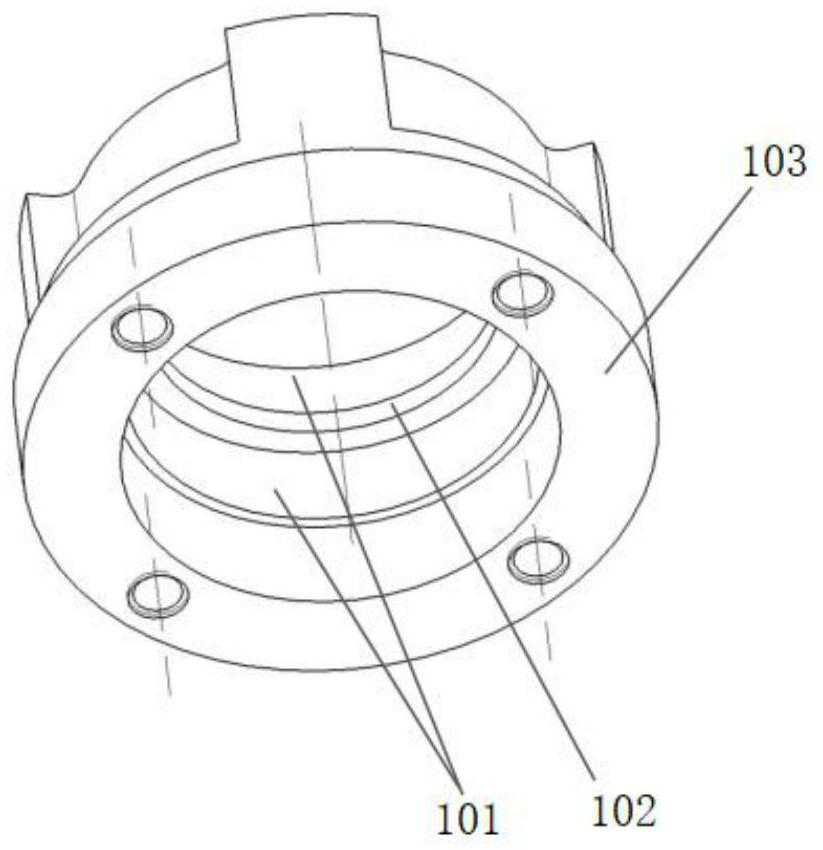

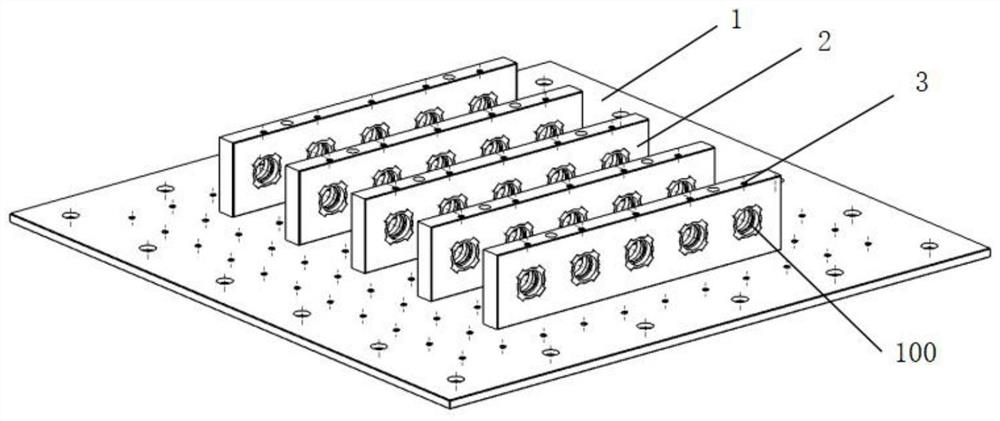

[0039] The measuring device is composed of a measuring plate 1, a fixing seat 2, and a fastening screw 3. image 3 A schematic diagram of the device is shown. The measuring plate is mainly used for the positioning and fixing of the fixing bases, and ensures that the distances between the fixing bases are equal. The fixing seat and fastening screws are mainly used for fixing the rotor bushings, and ensure that the distance between the rotor bushings in the fixing seat is equal. The fastening screws are mainly used for fixing the rotor bushings, and the rubber sleeve head 3.1 is fixed on the top to prevent Damage to the surface of the part.

[0040] Measuring plate:

[0041] The measuring plate is used for the positioning and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com