Quality-guaranteeing and efficient laying method of composite geomembrane applied to municipal engineering

A composite geomembrane, laying method technology, applied in metal processing, building material processing, force/torque/work measuring instrument, etc., can solve the problems of low intelligence, poor laying effect, undetectable laying effect, etc. The effect of fit tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

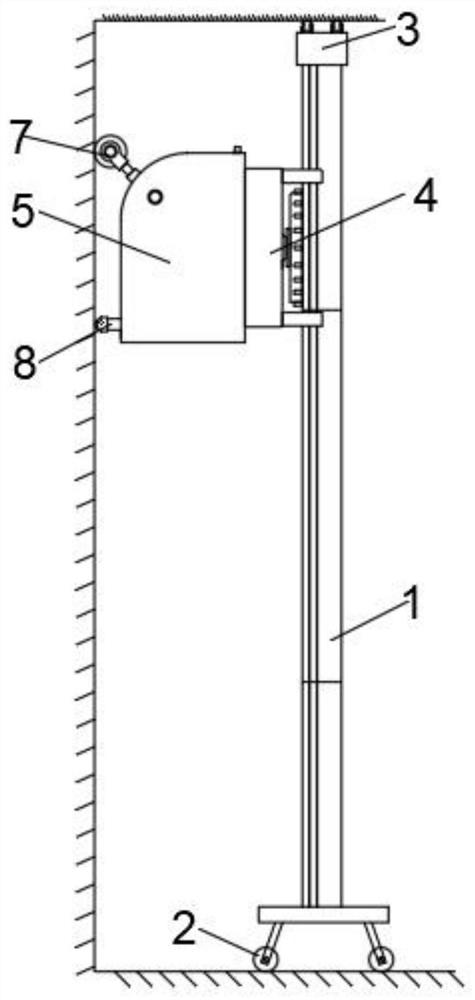

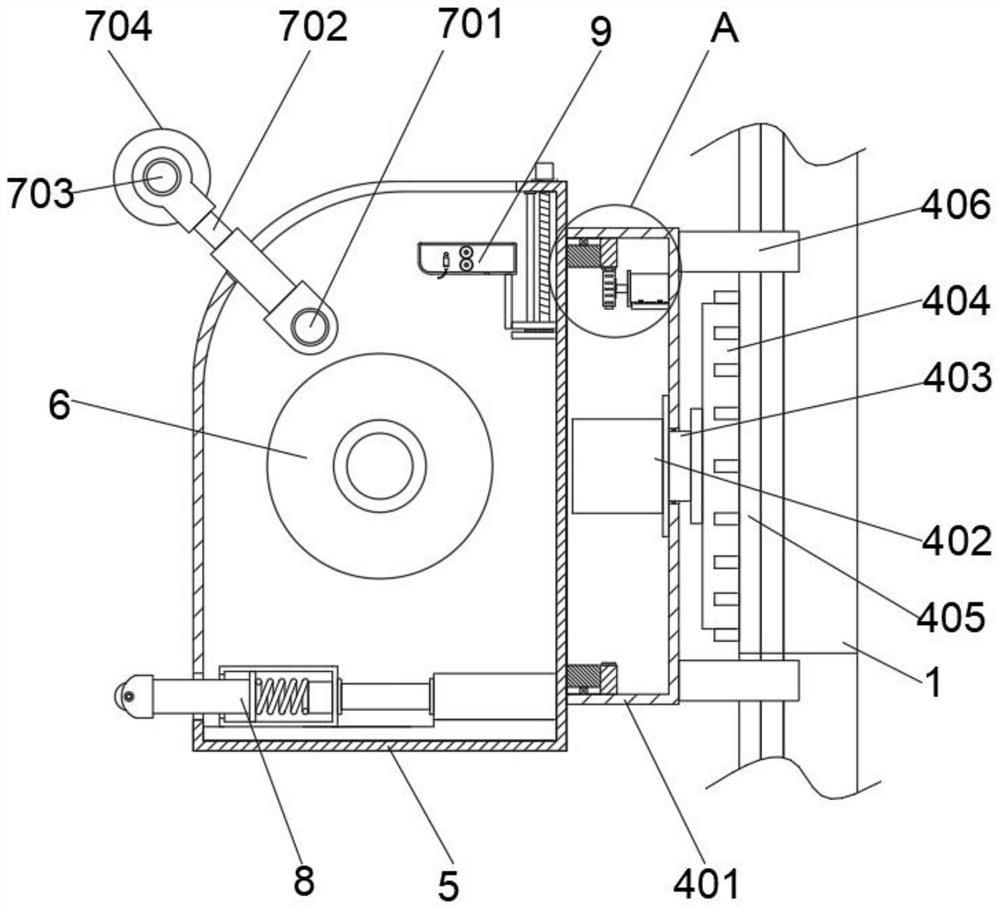

[0038] A quality and high-efficiency laying device applied to a composite geomembrane applied to municipal engineering, including spliced support frame 1, bottom electric universal wheel 2, top electric universal wheel 3, layered box 5, material reel 6, laying assembly 7, The detection component 8 and the cutting assembly 9, the bottom electric universal wheel 2 and the top electric universal wheel 3 are separated at both ends of the spliced support frame 1, the bottom electric universal wheel 2 and the top electric universal wheel 3 cooperate with The moving device, the spliced support frame 1 causes the height of the device to be adjusted, and the side of the laying box 5 adapts the multi-function drive structure 4, and the multi-function drive structure 4 is used to drive the laying box 5 for rotation and lift, multi-function drive structure. 4 is connected to the spliced support frame 1, and the material reel 6 is rotated within the laying box 5, and the material reel ...

Embodiment 2

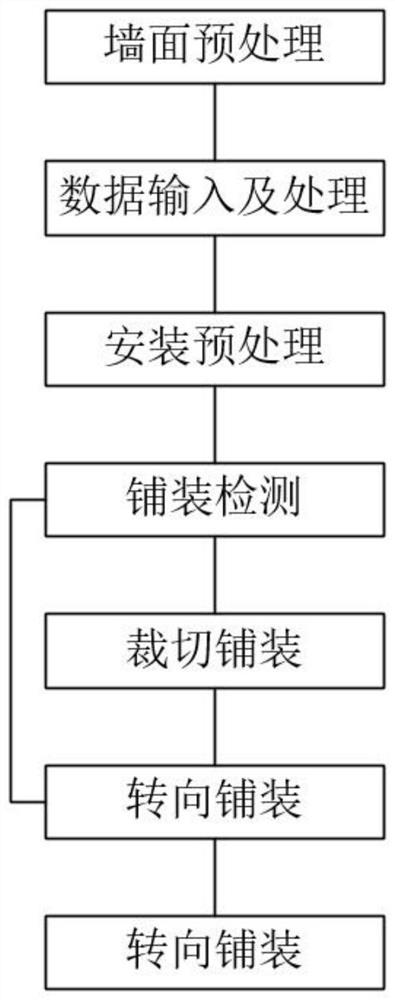

[0052] Based on Example 1, a composite geomembrane method applied to the municipal engineering, the specific work steps are as follows:

[0053] Step 1, wall pretreatment: Before laying a composite geomembrane, first spraying a waterproofing coating;

[0054] Step II, data input and processing: Enter the target area of the wall surface from the display terminal, that is, the area, length, and height of the wall needs to be laid, and then select the material reel 6 of the appropriate width according to the length of the wall; in which the material can be 6 The outer end of the 6 has a composite soil film, wherein the material reel 6 of the suitable width is specifically manifested as the length of the wall, and the width of the composite geomembrane is not an integral multiple;

[0055] Step 3, after installing the pretreatment: After the material reel 6 is mounted to the laying box 5, the one end of the composite geostate passes through the feed guide groove 914 of the guide box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com