Rapid lineation device for bench worker

A scribing device and fast technology, applied in the field of fitter processing, can solve the problems of different depths of scribed lines, crooked drawing, low efficiency of manual scribing, etc., and achieve the effect of accurate proofing, punching and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

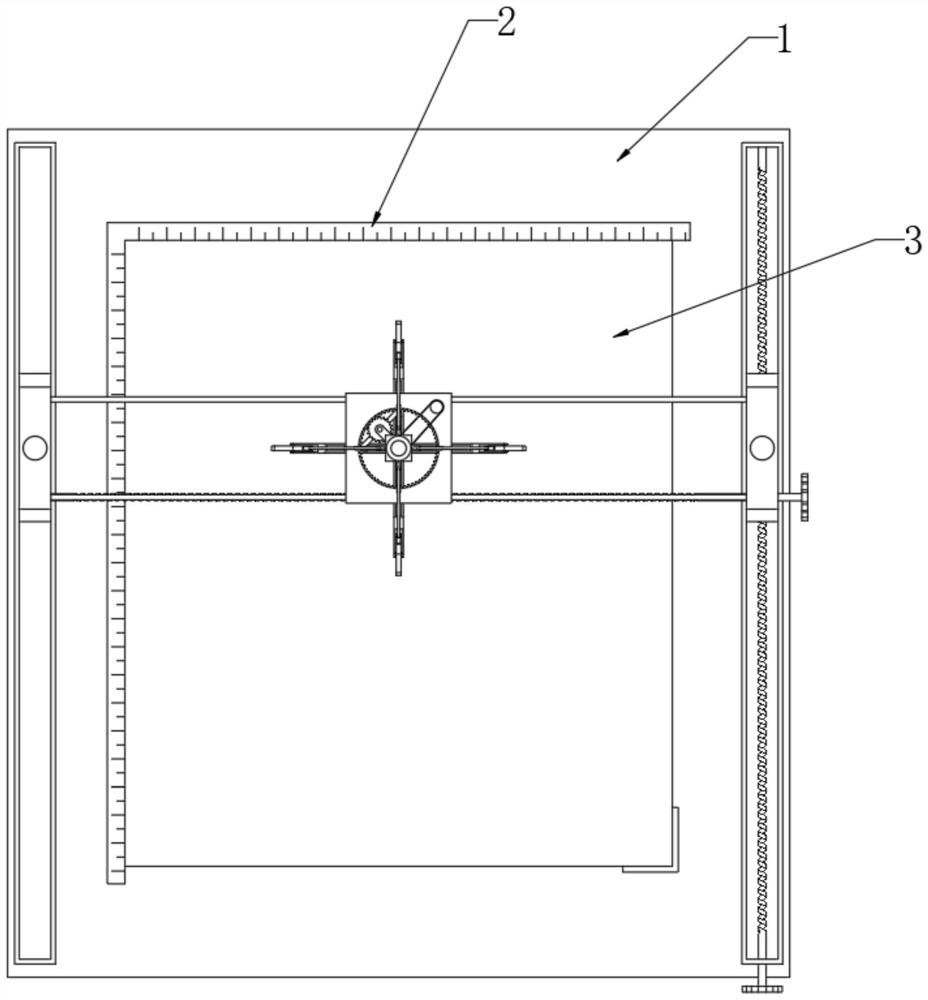

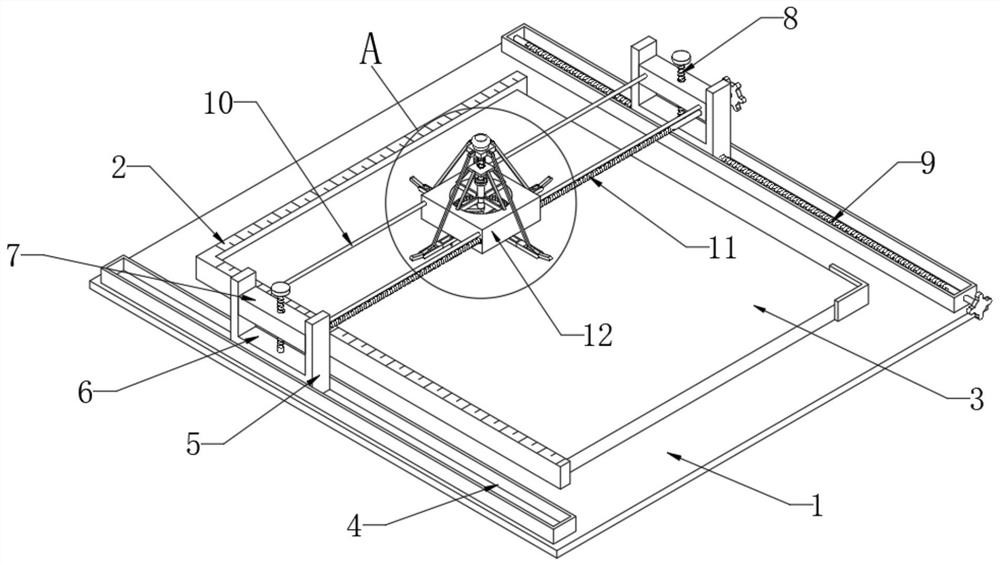

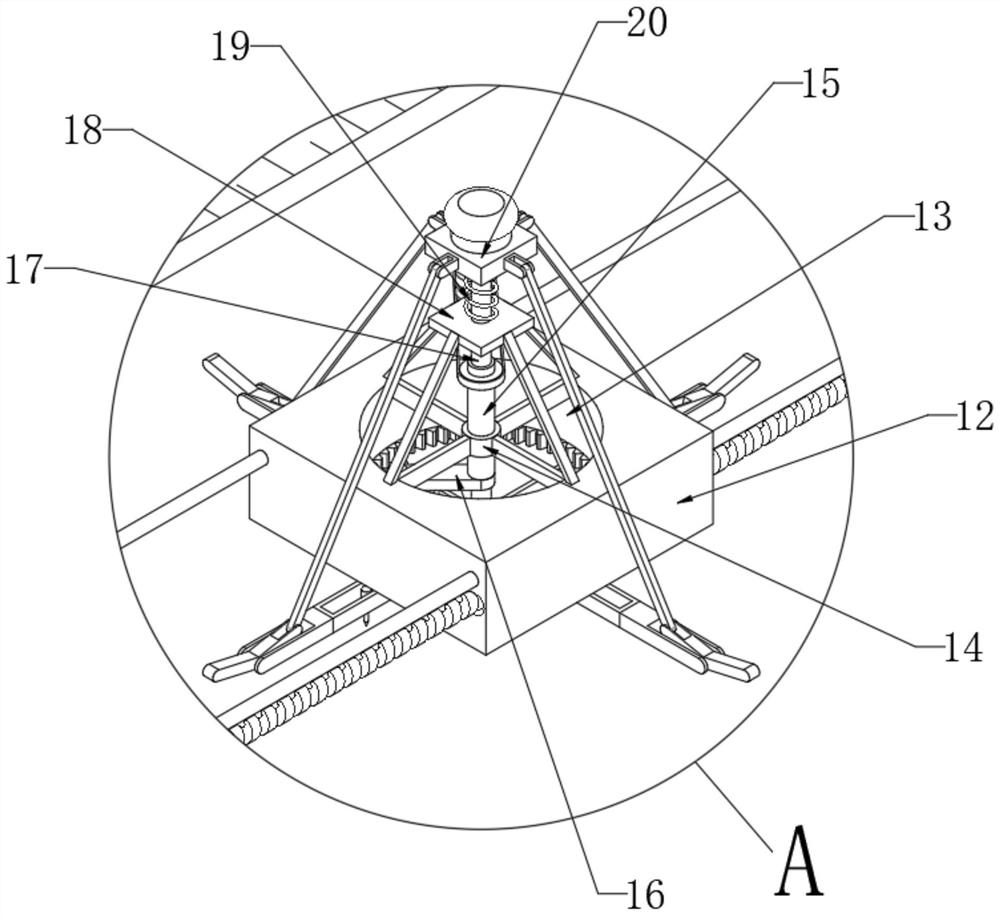

[0027] See Figure 1 to 6 The present invention provides a technical solution: a fast scribing device for fitter, including the bottom plate 1, the top of the bottom plate 1 fixes a straight angle card 2 for the two right angles of the workpiece 3, the bottom plate 1 The top is provided with a fixed component for fixing the workpiece 3, and the upper surface of the two right arms of the right angle card 2 opens the scale, and a scribe mechanism is also provided on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com