Transmission device of multi-working-condition intelligent batching system and control method

A technology of intelligent batching and transmission device, which is applied in chemical instruments and methods, transportation and packaging, mixer accessories, etc., to meet the requirements of interchangeability, facilitate installation and disassembly, and improve product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

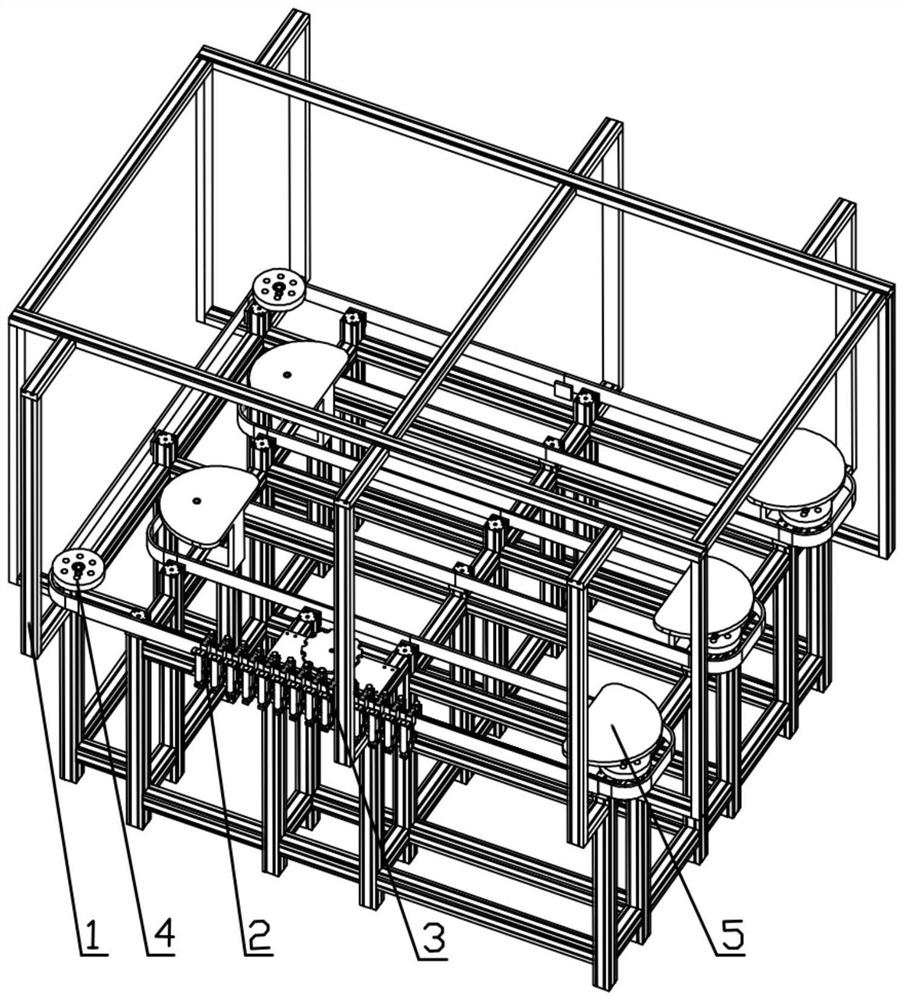

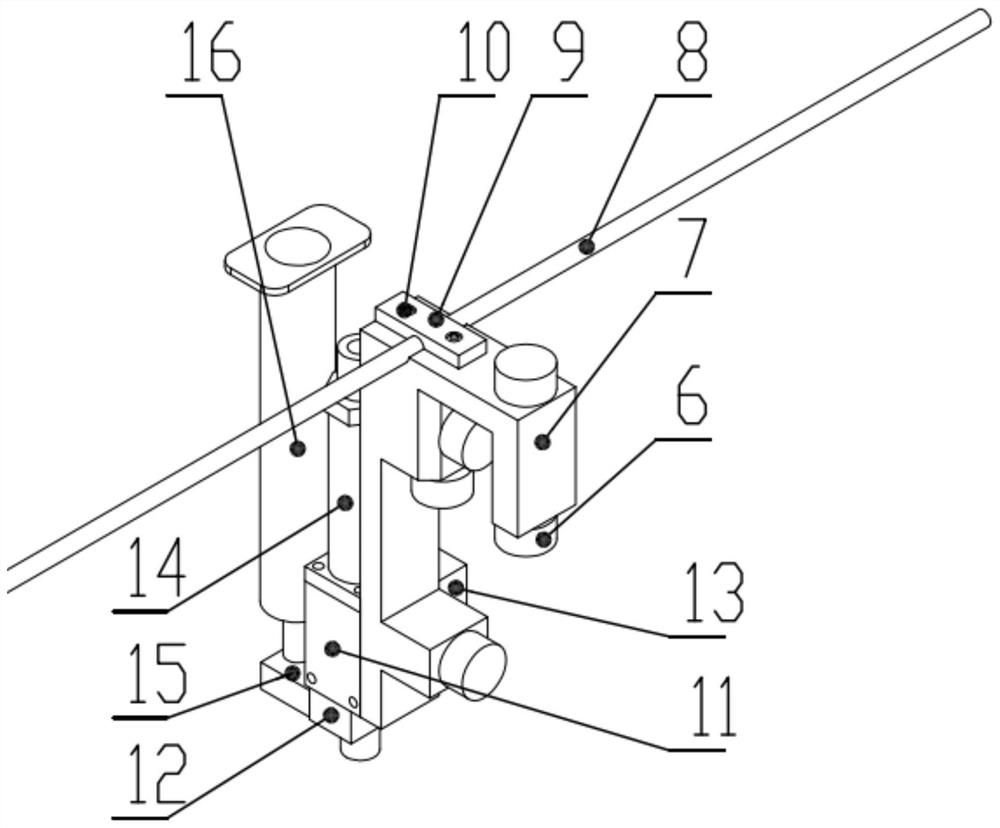

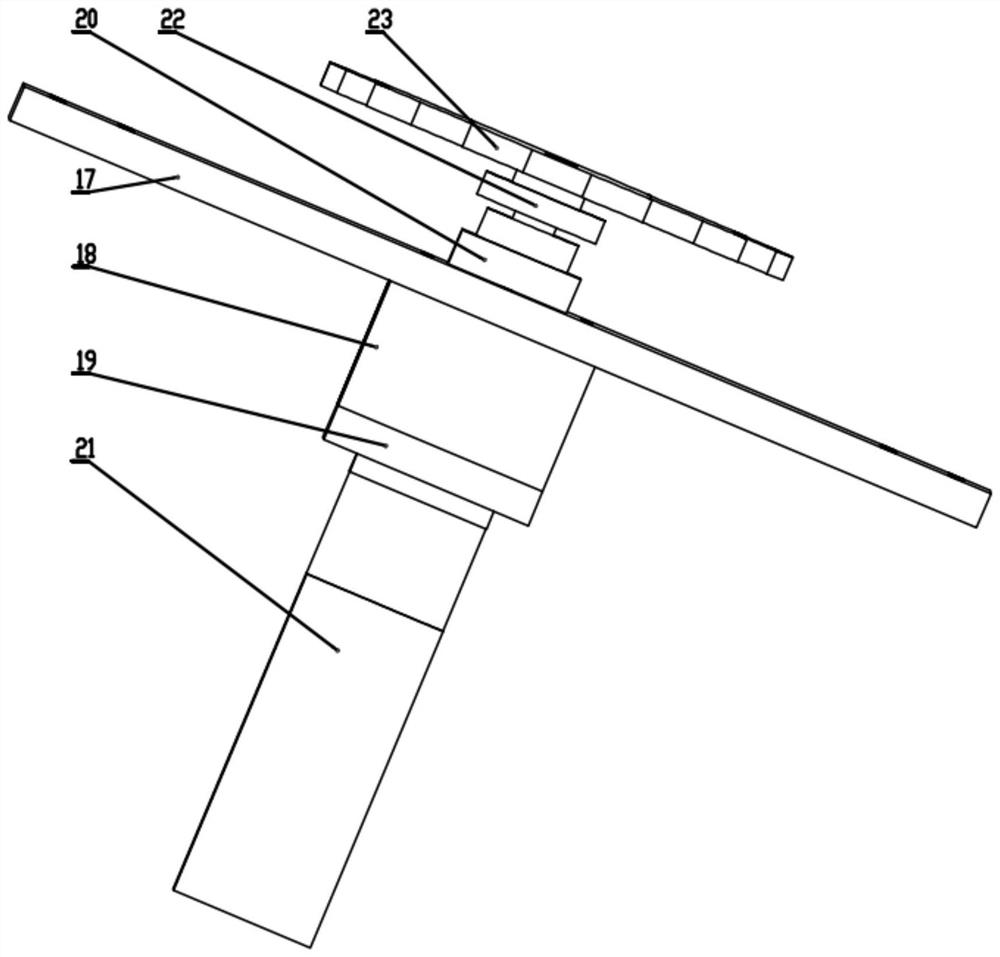

[0032] To better illustrate the contents of the invention, the following will be described below with reference to the accompanying drawings and the embodiments:

[0033] have Figure 1 - Figure 7 As shown, the present invention discloses a plurality of working-shaped intelligent bracketing systems, including transmission brackets 1, rail walking frame 2, turntable rotating assembly 3, synchronous pulley 4, wheel frame 5, rail walk frame 2 including a wheel The frame 7, and the wheel frame 7 can be rotated to be provided with a plurality of step wheel 6, and the track wrapper 2 is contracted by the walk wheel 6 and the moving track (not shown), the walk wheel 6 rolls connected to the moving track, the track walker 2 passes The wire rope 8 is connected, and a pressure plate 9 is provided on the upper side of the wire rope 8. The pressure plate 9 is fixedly coupled to the wheel frame 7 by a fixed bolt 10, and a main valve body 11 is provided on the wheel frame 7, and the main valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com