All-solid-state thick-film lithium battery and preparation method thereof

An all-solid-state lithium battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low battery capacity, achieve small volume changes, high production efficiency, and improve ion diffusion capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing an all-solid-state thick-film lithium battery, comprising the following steps:

[0043] (1) The positive electrode active material LiCoO 2 , conductive carbon black, binder polyvinylidene fluoride and solid electrolyte Li 3 PO 4 Mix evenly in N-methylpyrrolidone liquid medium to make positive electrode slurry; wherein, the mass ratio of positive electrode active material, solid electrolyte, conductive agent and binder is: 8:0.5:0.5:1;

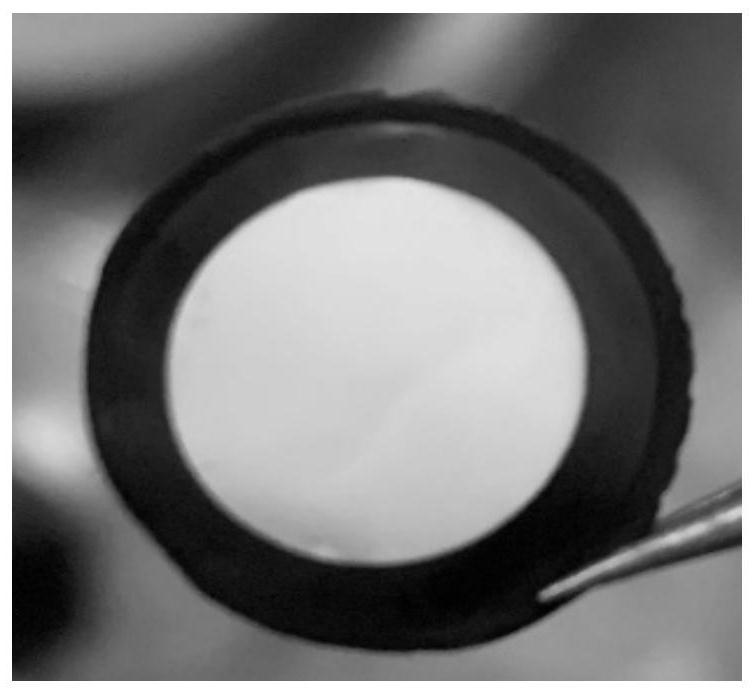

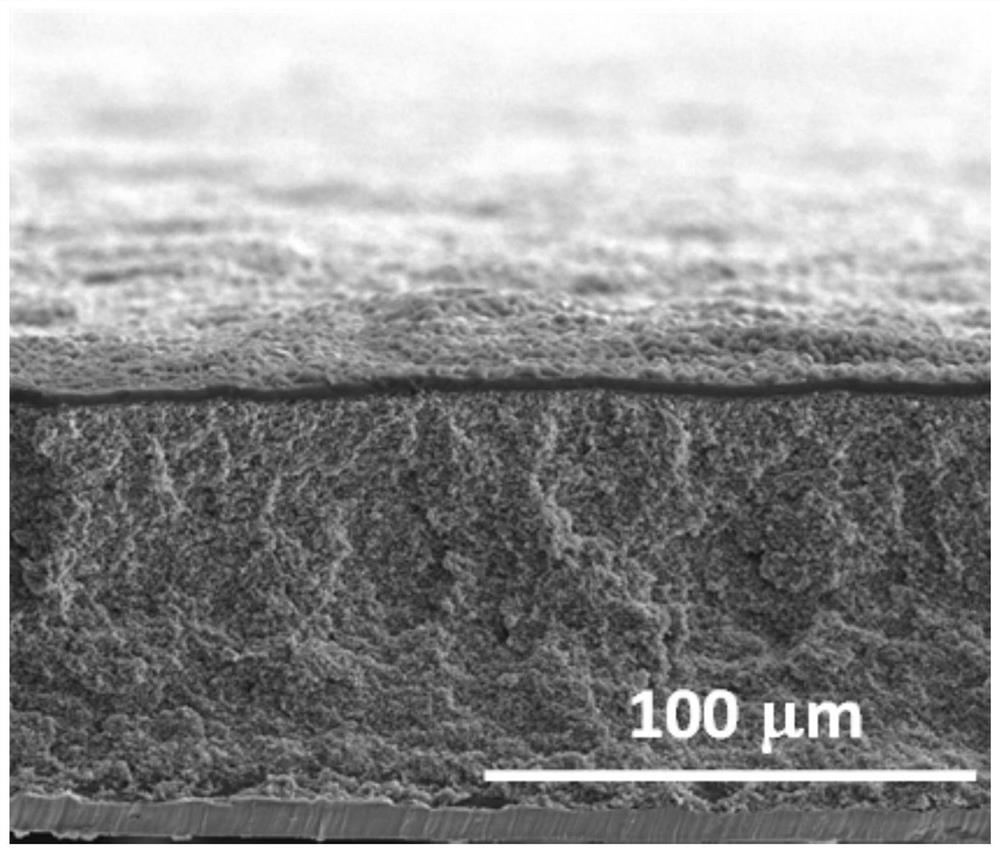

[0044] (2) The positive electrode slurry was printed on the positive electrode current collector aluminum foil by casting method printing equipment, then dried in a blast oven at 60°C for 6h, and then transferred to a vacuum oven at -0.1MPa and 110°C for 10h, Finally, it was flattened with a roller press to obtain a thick film positive electrode with a thickness of 95 μm;

[0045] (3) The electrolyte material LiPON is prepared on the thick film positive electrode with a thickness of 9 μm LiPON thin film electrol...

Embodiment 2

[0048] A method for preparing an all-solid-state thick-film lithium battery, comprising the following steps:

[0049] (1) The positive electrode active material LiMn 2 o 4 , conductive agent conductive carbon black, binder polyvinylidene fluoride and solid electrolyte LLTO are uniformly mixed in N-methylpyrrolidone liquid medium to prepare positive electrode slurry; among them, positive electrode active material, solid electrolyte, conductive agent and binder The mass ratio of the agent is: 4:3.5:1.5:1;

[0050] (2) The positive electrode slurry was printed on the positive electrode current collector aluminum foil by casting method printing equipment, then dried in a blast oven at 60°C for 6h, and then transferred to a vacuum oven at -0.1MPa and 110°C for 10h, Finally, it was flattened with a roller press to obtain a thick film positive electrode with a thickness of 120 μm;

[0051] (3) The electrolyte material LiPON is prepared on the thick film positive electrode by magne...

Embodiment 3

[0054] A method for preparing an all-solid-state thick-film lithium battery, comprising the following steps:

[0055] (1) The positive electrode active material LiFePO 4 , Conductive agent Conductive carbon black, binder polyvinylidene fluoride and solid electrolyte are uniformly mixed in N-methylpyrrolidone liquid medium to prepare positive electrode slurry; wherein, positive active material, solid electrolyte, conductive agent and binder The mass ratio is: 6:1.5:1.5:1, the solid electrolyte is a mixture of PAN and LiTFSI (AN and Li + The molar ratio is 4:1);

[0056] (2) Print the positive electrode slurry on the positive electrode current collector aluminum foil by screen printing equipment, then dry it in a blast oven at 60°C for 6h, then transfer it to a vacuum oven at -0.1MPa and 110°C for 10h, and finally Flatten with a roller press to obtain a thick film positive electrode with a thickness of 500 μm;

[0057] (3) The electrolyte material LLTO is prepared on the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com