Processing line mistake proofing system and method, storage medium, electronic equipment and production line

An error-proof system and processing line technology, applied in the field of automation, can solve the problems of long detection time, unable to stop the production line in time, complex detection equipment of the automatic production line, inconvenient installation and maintenance, etc., and achieve short recognition time, low cost and flexible recognition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

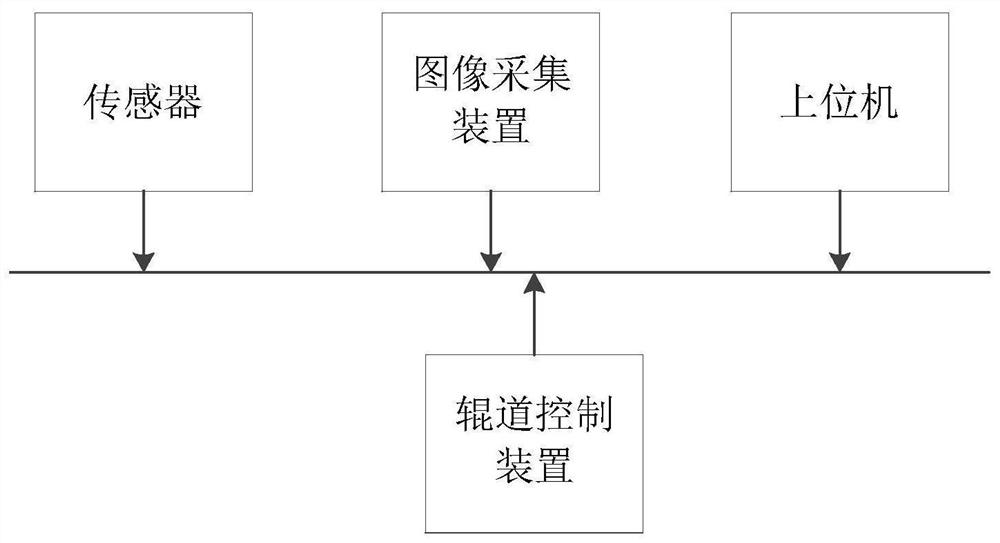

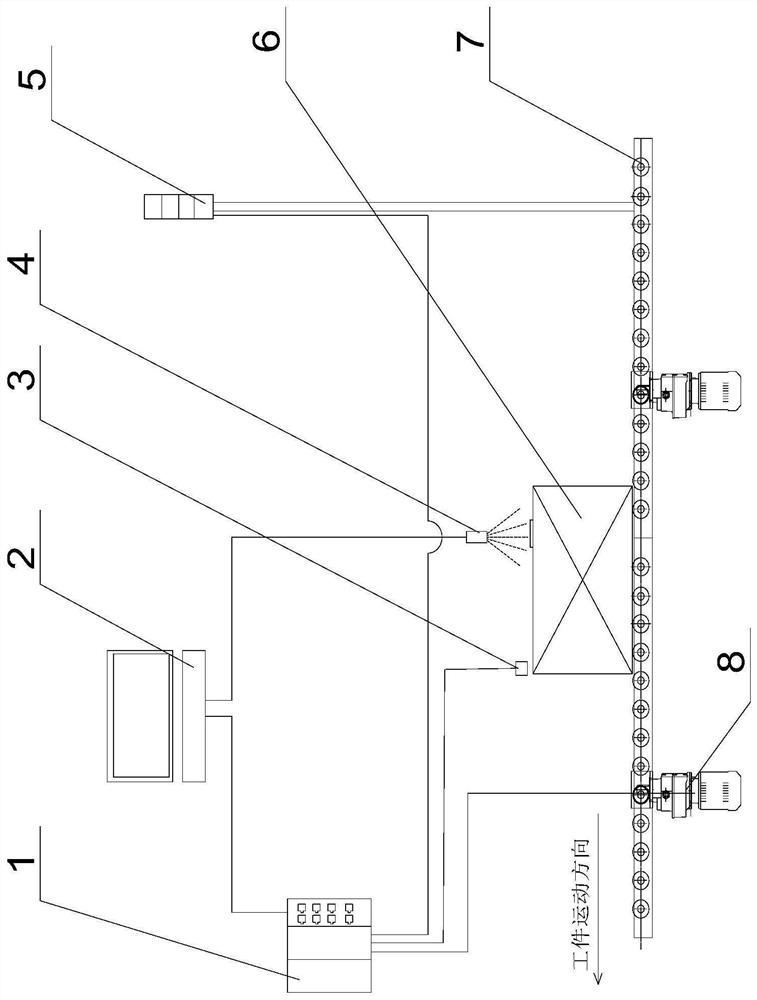

[0053] figure 1 It is a schematic diagram of a processing line error prevention system provided in the embodiment of this application. This system includes:

[0054] Sensor, image acquisition device, upper computer, roller table control device;

[0055] The sensor is arranged at a first preset position on the processing line, and is used to send in-position signals to the roller table control device and the host computer respectively when a workpiece to be inspected is detected;

[0056] The image acquisition device is arranged at a second preset position on the processing line, and is used to acquire images of processing features of the workpiece to be inspected;

[0057] The host computer is respectively connected to the image acquisition device and the roller table control device, and is used to control the image acquisition device to acquire images based on the in-position signal, and to process the images;

[0058] judging whether the image contains features to be detec...

Embodiment 2

[0089] Figure 4 A schematic flow chart of a processing line error-proofing method provided in the embodiment of the present application, as shown in Figure 4 As shown, the method includes:

[0090] S110: Obtain in real time the information of the workpiece to be inspected at the preset position of the processing line, and determine whether the workpiece to be inspected has arrived at the preset position;

[0091] S120: If it is judged that the workpiece to be inspected has arrived at the preset position, send an in-position signal;

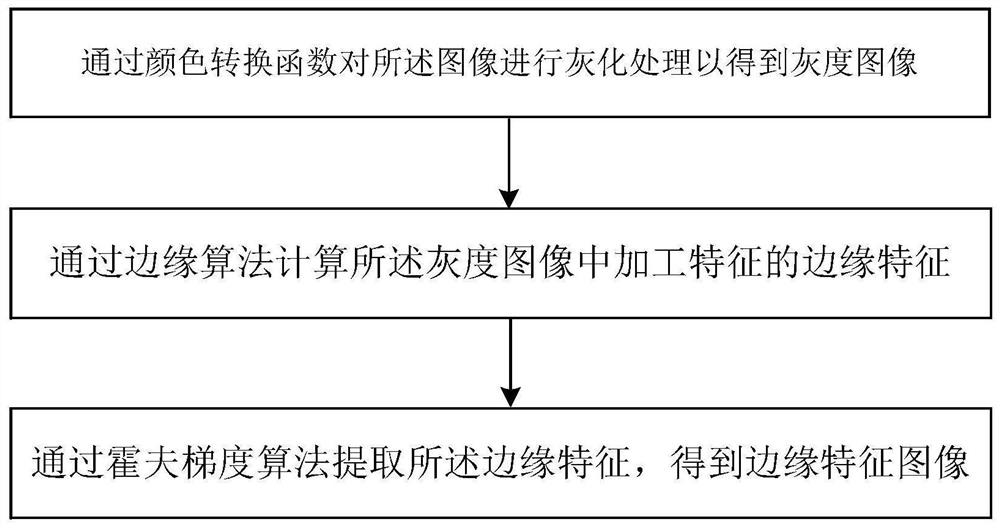

[0092] S130: Obtain an image of the processing feature of the workpiece to be inspected according to the in-position signal, and process the image;

[0093] S140: Judging whether the image contains features to be detected, and if so, judging whether the features to be detected meet requirements, and feeding back preset information corresponding to the judgment results according to the judgment results;

[0094] S150: Control the running and s...

Embodiment 3

[0107] This embodiment also provides a computer-readable storage medium, such as flash memory, hard disk, multimedia card, card-type memory (for example, SD or DX memory, etc.), random access memory (RAM), static random access memory (SRAM), only Read memory (ROM), electrically erasable programmable read-only memory (EEPROM), programmable read-only memory (PROM), magnetic memory, magnetic disk, optical disk, server, App application store, etc., on which computer programs are stored, When the computer program is executed by the processor, the steps of the method in Embodiment 2 can be implemented, and this embodiment will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com