Combustor and gas stove

A burner and gas cavity technology, which is applied in the field of cookers, can solve problems such as poor flame uniformity, and achieve the effects of good flame uniformity and improved cooking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

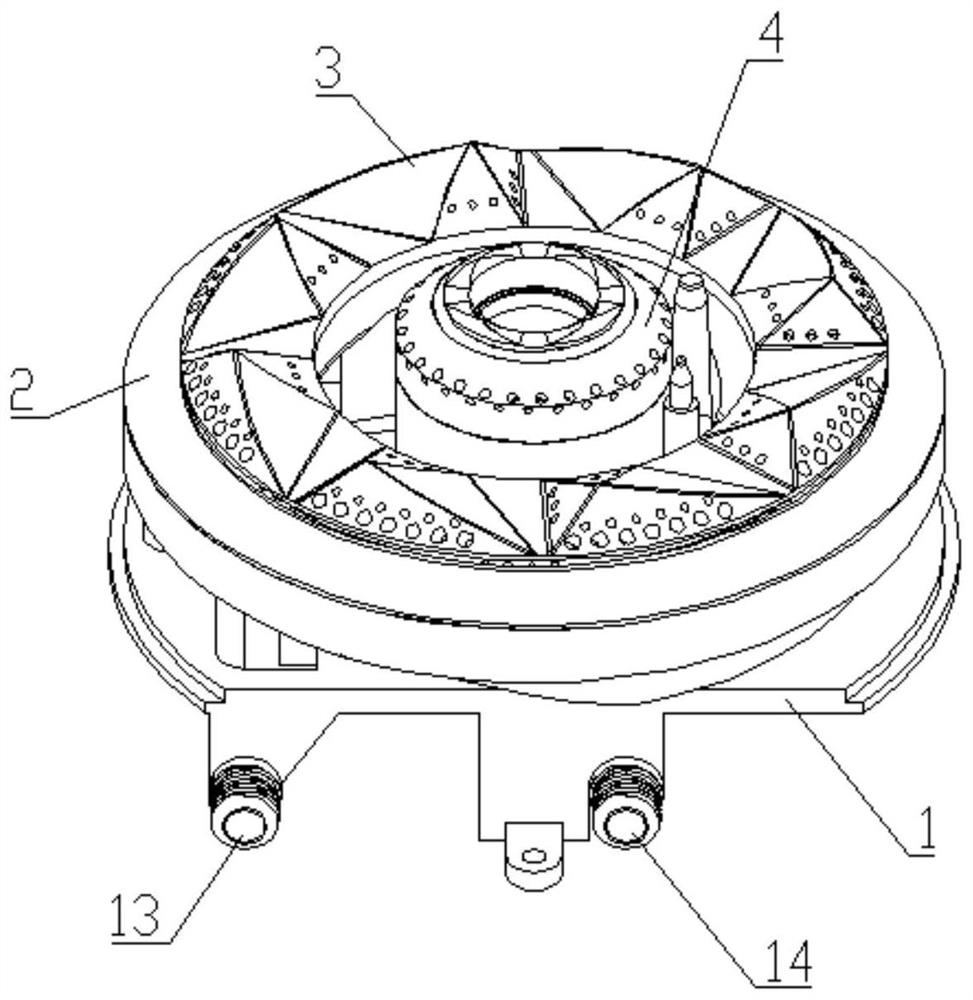

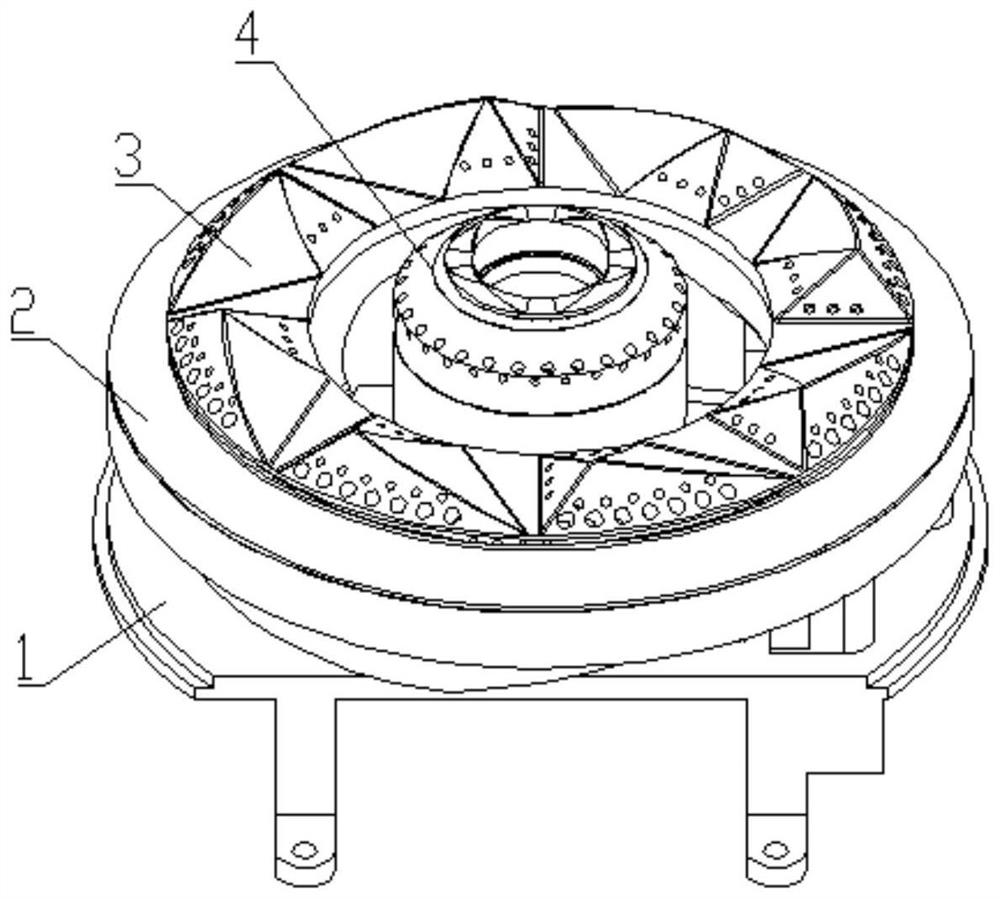

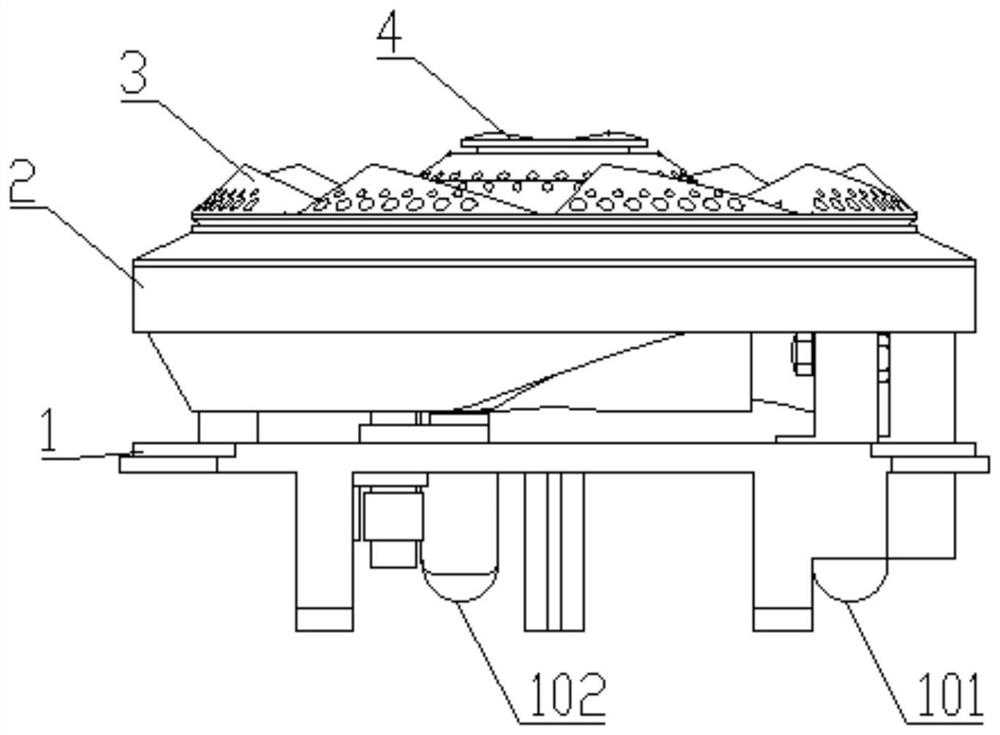

[0054] Such as Figure 1 to Figure 13 As shown, this embodiment provides a burner, including a burner head 2 and a nozzle seat 1. The burner head 2 is provided with an outer ring structure 21 and a central structure 22. The outer ring structure 21 is surrounded by the outer side of the central structure 22. The ring structure 21 includes an outer ring distribution air channel 212 and an outer ring ejector tube 211, the air outlet of the outer ring ejector tube 211 communicates with the outer ring distribution air channel 212, and the central structure 22 includes a central distribution air channel and a central ejector tube, The air outlet of the central injection tube communicates with the central distribution airway. The nozzle seat 1 includes a seat body, and a first air supply channel 11 is arranged in the seat, and the first air supply channel 11 communicates with an outer ring nozzle 1121 and a central nozzle, and the outer ring nozzle 1121 is opposite to the air inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com