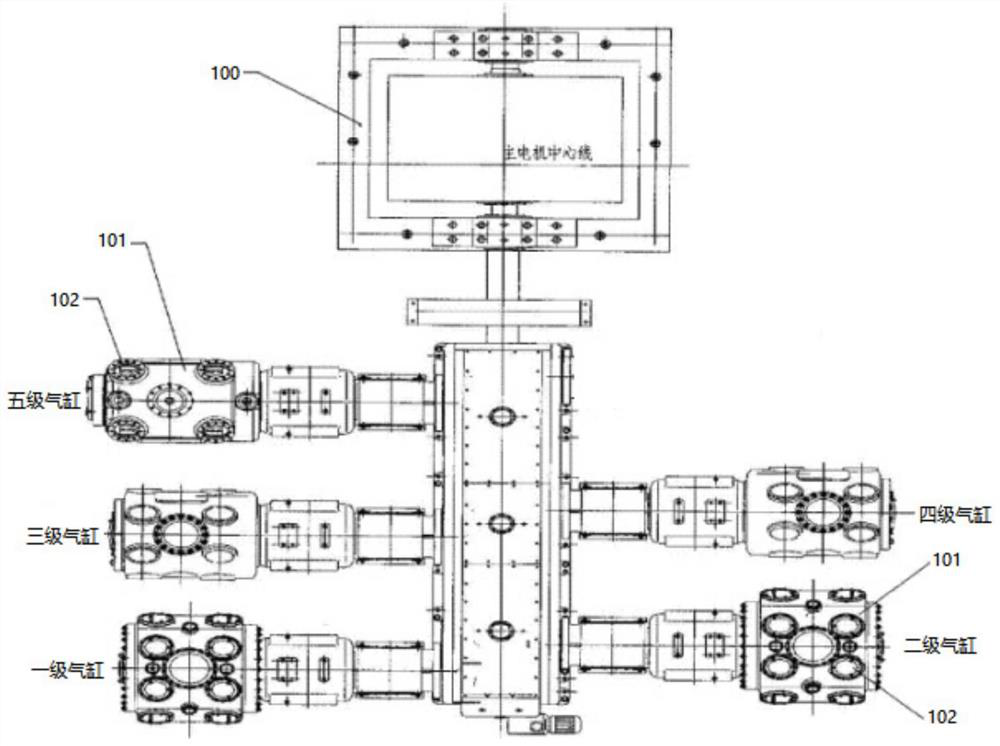

Energy-saving transformation method for high-pressure 4M32G-186 carbon dioxide compressor

A 4M32G-186, carbon dioxide technology, applied in the chemical industry, mechanical equipment, machines/engines, etc., can solve problems such as inability to obtain energy-saving effects, achieve major economic benefits, save energy, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The high-pressure 4M32G-186 carbon dioxide compressor in the compressor workshop of Jinneng Holding Equipment Manufacturing Group Tianyuan Shanxi Chemical Co., Ltd. was transformed as follows:

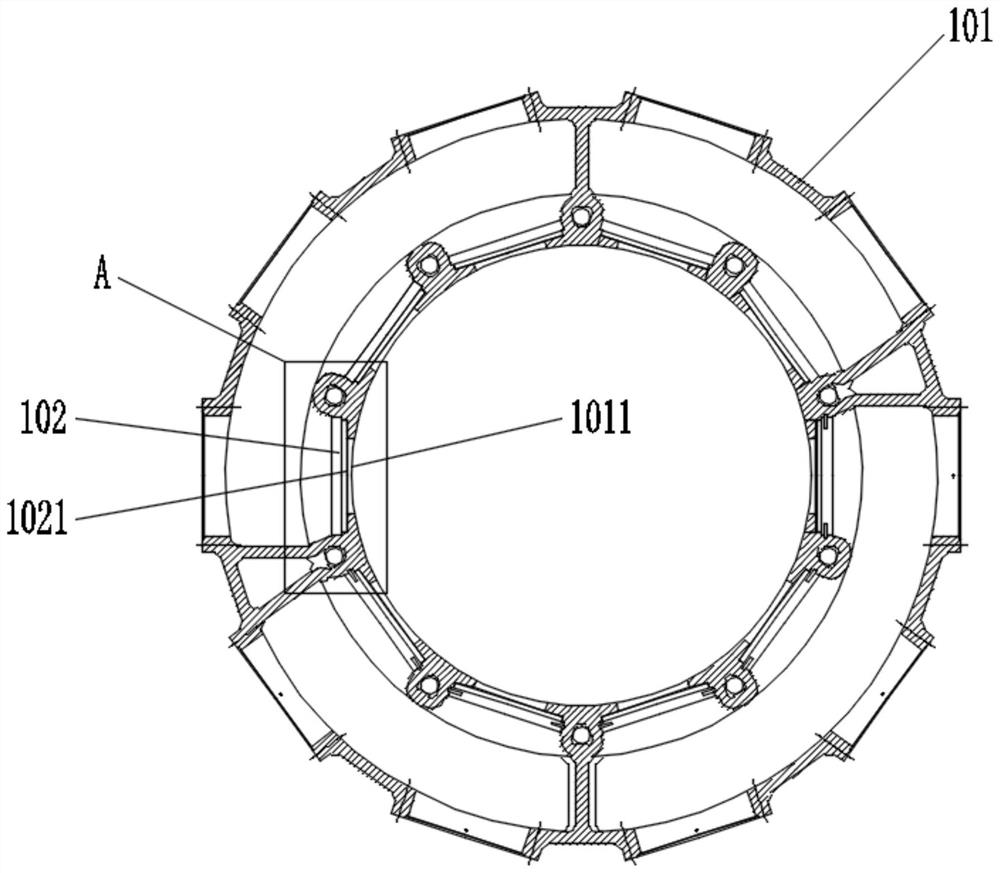

[0085] S1. Change the inner diameter of the first-stage cylinder from 1082mm to 1085mm, the inner diameter of the second-stage cylinder from 622mm to 625mm, the inner diameter of the third-stage cylinder from 282mm to 285mm, the inner diameter of the fourth-stage cylinder from 300mm to 303mm, and the inner diameter of the fifth-stage cylinder Internal diameter changed from 148mm to 155mm;

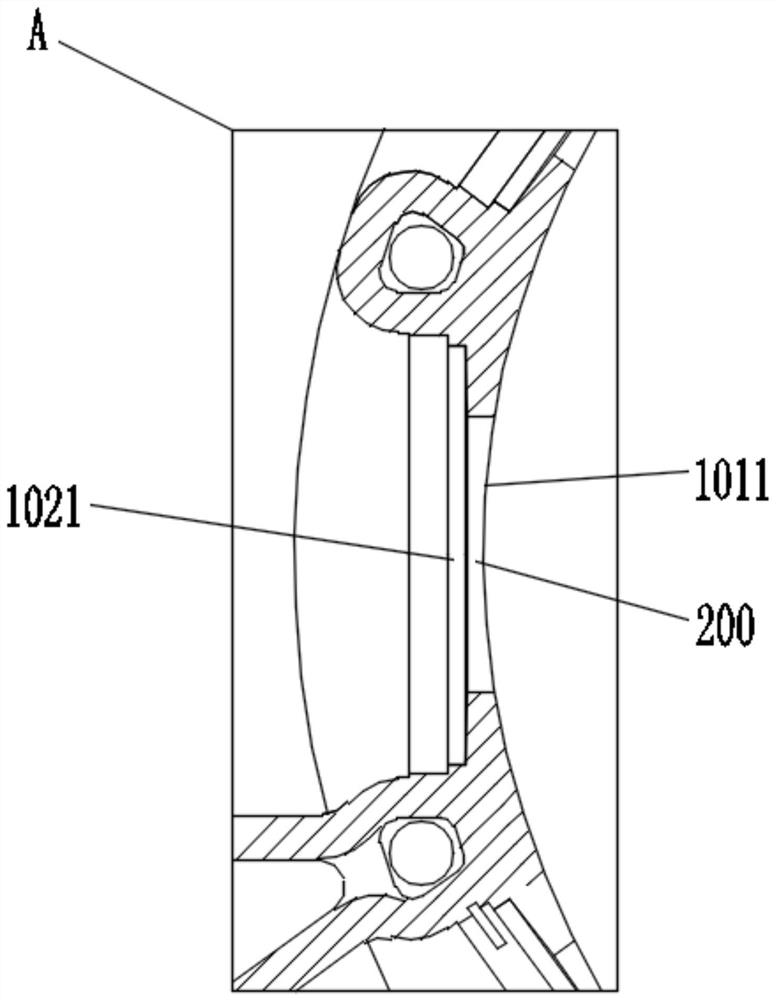

[0086] S2, the piston is changed from a split type to an integral type; and

[0087] Change the outer diameter of the first-stage piston from 1073mm to 1077mm, the outer diameter of the second-stage piston from 615mm to 619mm, the outer diameter of the third-stage piston from 276mm to 279mm, the outer diameter of the fourth-stage piston from 295mm to 297mm, and the outer diameter of the fifth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com