Double-acting clamping jig with shearing function

A dynamic clamping and jig technology, applied in the field of reclaiming jig, can solve the problems of material rod deformation and shorten the injection cycle, and achieve the effect of low cost, shortened injection cycle and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

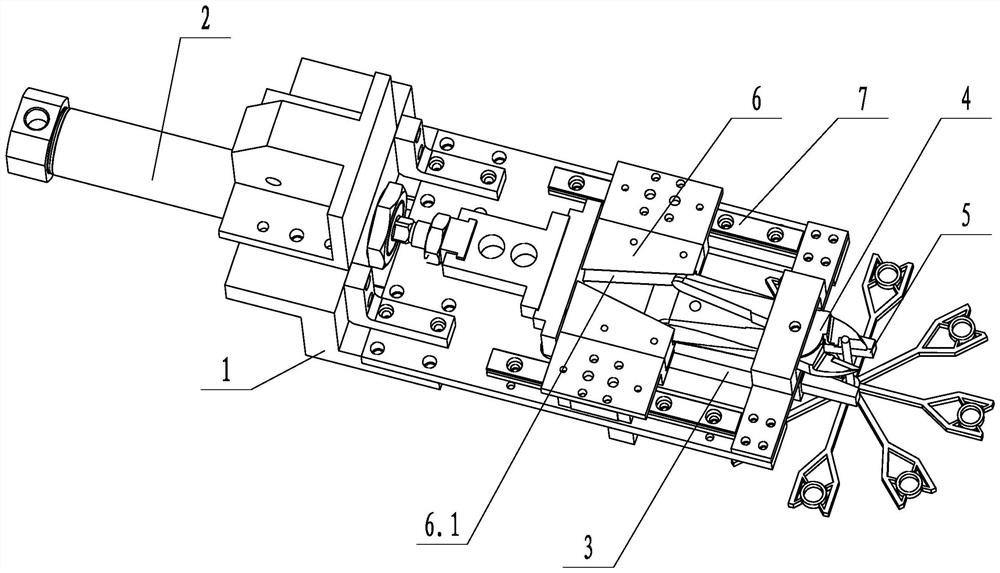

[0029] Such as figure 1 As shown, a double-action clamping fixture with shearing function includes a fixed frame 1, a first drive mechanism 2, a second drive mechanism 3, scissors 4, jaw blocks 5 and a first inclined push block 6, The first drive mechanism 2, the second drive mechanism 3 and the scissors 4 are respectively arranged on the fixed mount 1, the first drive mechanism 2 is a linear cylinder, the jaw block 5 is arranged below the scissors 4, and the first oblique pushing block 6 is connected to the fixed mount. 1 is slidably connected by the guide rail 7, the first driving mechanism 2 drives the first inclined push block 6 to slide, and the first inclined push block 6 is provided with a first guide groove 6.1, the first guide groove 6.1 is a V-shaped structure, and the first guide groove The big mouth of 6.1 faces the scissors 4, the handle of the scissors 4 is in contact with the side wall of the first guide groove 6.1, and the second driving mechanism 3 drives the ...

Embodiment 2

[0032]On the basis of Embodiment 1, the second drive mechanism 3 is a jaw cylinder. The structure can realize the independent driving of the jaw block 5, so that the jaw block 5 can clamp the material rod of the product under the action of the jaw cylinder.

Embodiment 3

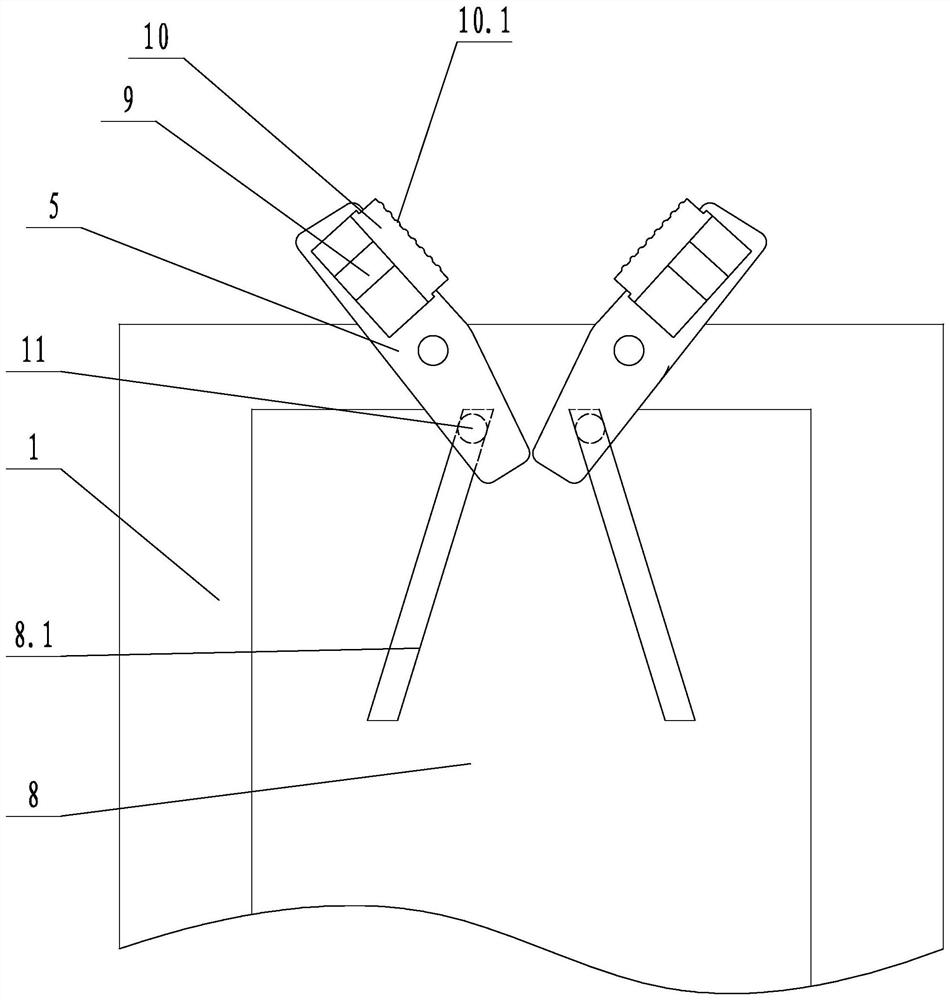

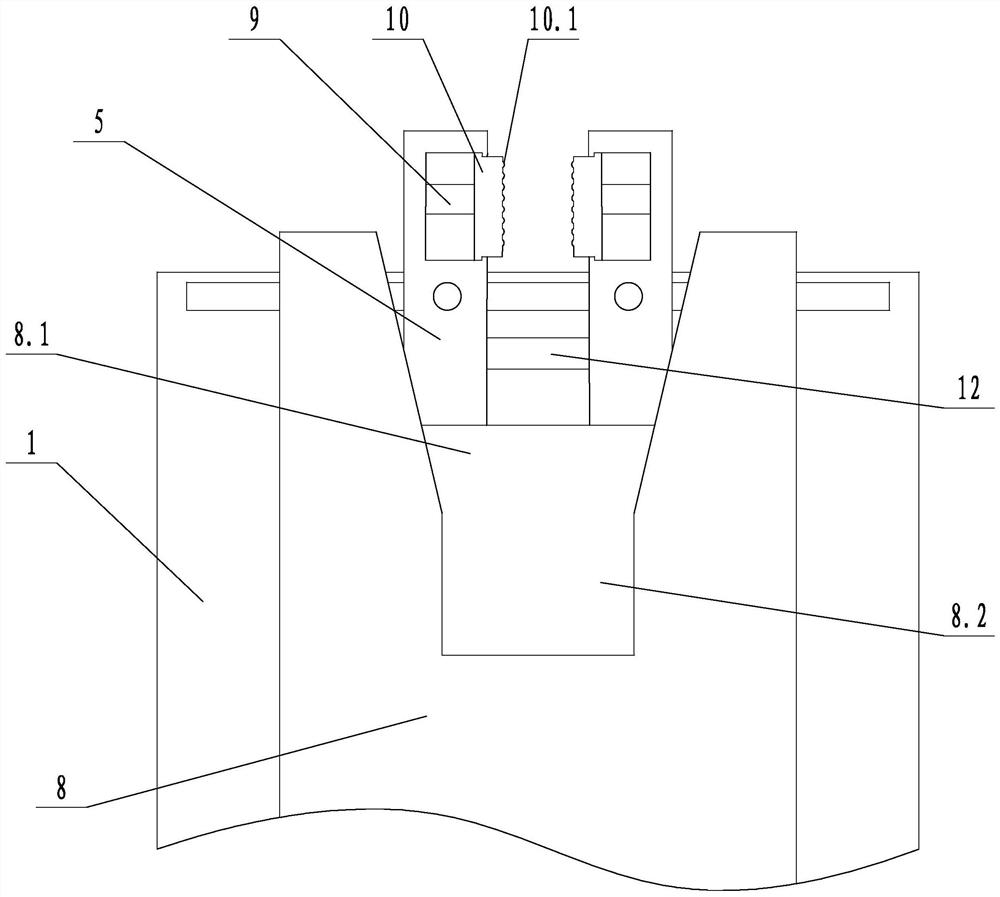

[0034] Such as figure 2 As shown, on the basis of Embodiment 1, the second driving mechanism 3 includes a second inclined push block 8, the second inclined push block 8 is fixed to the first inclined push block 6, and the second inclined push block 8 is provided with There are two second guide grooves 8.1 and two jaw blocks 5, one end of the jaw block 5 is hinged to the fixed frame 1, and the other end of the jaw block 5 is slidably connected to the corresponding second guide groove 8.1. The jaw block 5 is provided with a sliding column 11, which is slidingly connected with the second guide groove 8.1, and the jaw block 5 is slidingly connected with the second guide groove 8.1 through the sliding column 11. The jaw block 5 is provided with a compression spring 9 and a contact block 10, the contact block 10 is slidingly connected with the jaw block 5, one end of the compression spring 9 is connected with the jaw block 5, and the other end of the compression spring 9 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com