Shaping, injection molding and edge closing method for women sandals

A technology for sandals and women's clothing, which is applied to the field of molding, injection molding, and edging of women's sandals, can solve problems such as wearing discomfort, and achieve the effects of improving wearing comfort, reducing indentation, and improving wearing experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

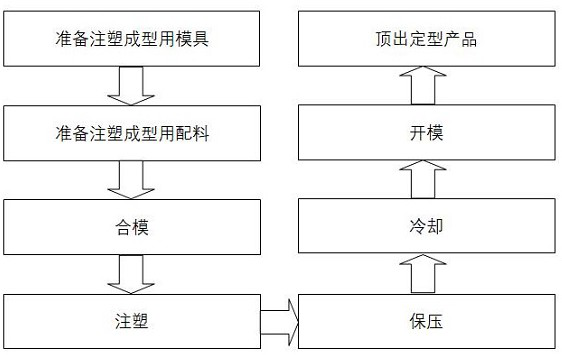

[0034] like Figure 1-2 As shown in , a method for trimming and edge trimming of women's sandals provided by an embodiment of the present invention includes the following steps:

[0035] Step 1, preparing a mold for injection molding, the mold for injection molding includes:

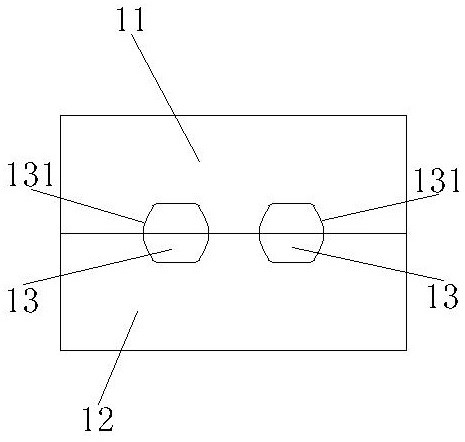

[0036] The front shoe upper forming upper mold 11, the front shoe upper forming lower mold 12 opposite to the front shoe upper forming upper mold 11; the front shoe upper forming upper mold 11 and the front shoe upper forming lower mold 12 A first molding cavity 13 is formed, and both sides of the first molding cavity 13 are arc edges 131;

[0037] an upper mold for upper back molding, and a lower mold for upper upper molding opposite to the upper mold for upper rear molding; The...

Embodiment 2

[0055] A method for shaping and trimming injection molding of women's sandals, comprising the following steps:

[0056]Step 1, preparing a mold for injection molding, the mold for injection molding includes:

[0057] The front shoe upper forming upper mold 11, the front shoe upper forming lower mold 12 opposite to the front shoe upper forming upper mold 11; the front shoe upper forming upper mold 11 and the front shoe upper forming lower mold 12 A first molding cavity 13 is formed, and both sides of the first molding cavity 13 are arc edges 131;

[0058] an upper mold for upper back molding, and a lower mold for upper upper molding opposite to the upper mold for upper rear molding; There is a second molding cavity, and the edge of the second molding cavity is an arc edge;

[0059] an upper mold for forming the upper buckle, and a lower mold for forming the upper buckle opposite to the upper mold for forming the upper buckle; between the upper mold for forming the upper buckl...

Embodiment 3

[0076] A method for shaping and trimming injection molding of women's sandals, comprising the following steps:

[0077] Step 1, preparing a mold for injection molding, the mold for injection molding includes:

[0078] The front shoe upper forming upper mold 11, the front shoe upper forming lower mold 12 opposite to the front shoe upper forming upper mold 11; the front shoe upper forming upper mold 11 and the front shoe upper forming lower mold 12 A first molding cavity 13 is formed, and both sides of the first molding cavity 13 are arc edges 131;

[0079] an upper mold for upper back molding, and a lower mold for upper upper molding opposite to the upper mold for upper rear molding; There is a second molding cavity, and the edge of the second molding cavity is an arc edge;

[0080] an upper mold for forming the upper buckle, and a lower mold for forming the upper buckle opposite to the upper mold for forming the upper buckle; between the upper mold for forming the upper buck...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com