Kitchen garbage recycling processor

A kitchen waste recycling technology, which is applied in the direction of presses, manufacturing tools, and solid waste removal, can solve problems such as unfavorable placement and use, kitchen waste feeding, and large extrusion chamber volume, and realizes small The effects of streamlined design, reduced design requirements, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

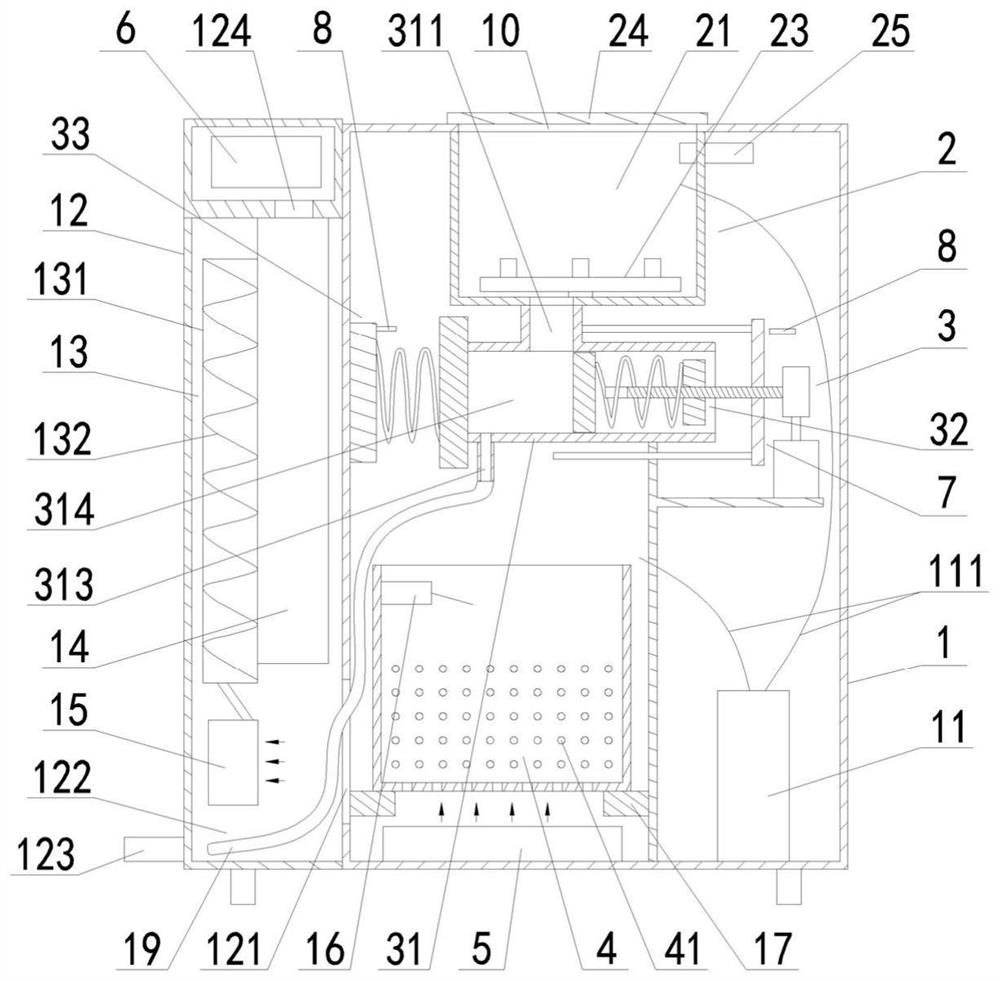

[0054] Such as figure 1 and Figure 10 As shown, the extrusion molding mechanism includes a forward pressure mechanism 32 and a reverse pressure mechanism 33, wherein the reverse pressure mechanism 33 seals the molded waste outlet 312 under normal conditions, and the quantitative extrusion cylinder 31 is positively pressed The mechanism 32 and the reverse pressing mechanism 33 form a quantitative forming cavity 314 for filling and compressing the crushed kitchen waste into small pieces. The reverse pressing mechanism 33 compresses the kitchen waste into small pieces. Finally, the top pressure is released to open the molded garbage outlet 312, so that the kitchen waste compressed into small pieces is pushed out of the quantitative molding cavity 314 by the forward pressure mechanism 32 and falls into the garbage collection bucket 4. The feeding port 311 is located at the quantitative molding The top of the chamber 314 is in communication with the pulverizing pool 21, and the d...

Embodiment 2

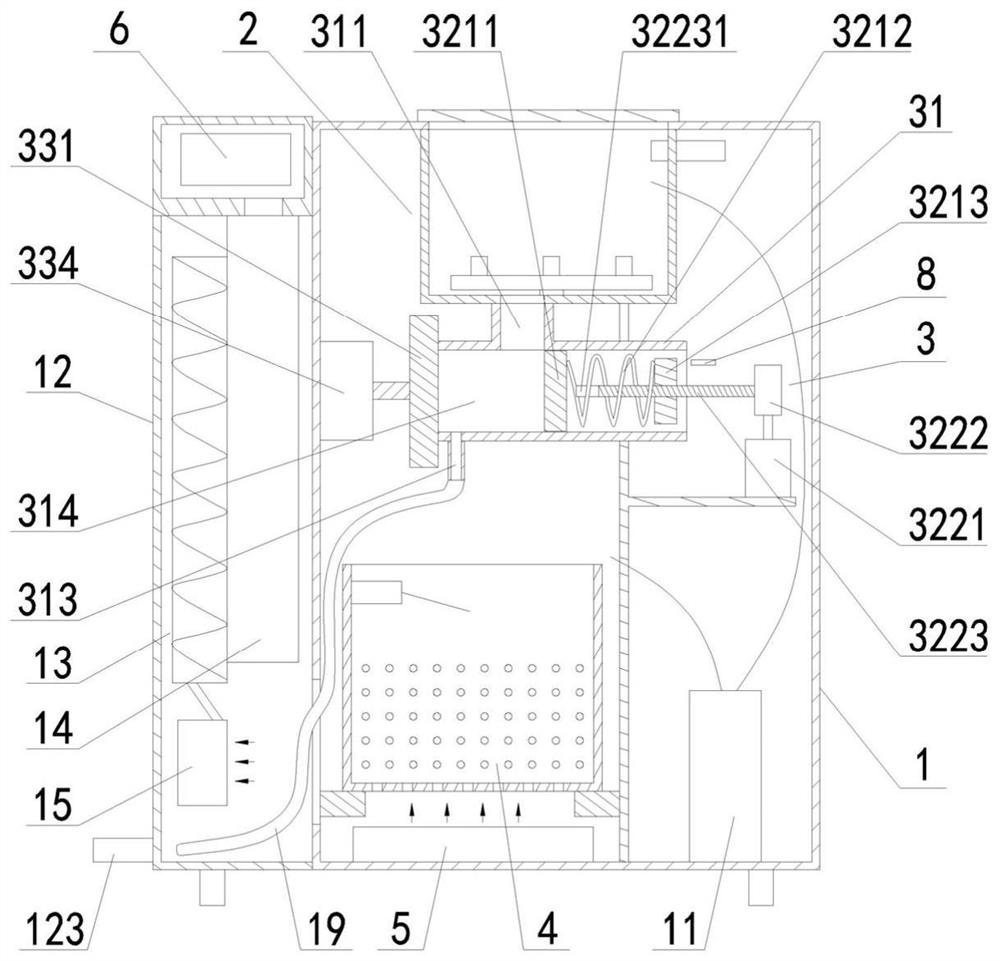

[0059] Such as figure 2 As shown, the extrusion molding mechanism includes a forward pressure mechanism 32 and a reverse pressure mechanism 33, wherein the reverse pressure mechanism 33 seals the molded waste outlet 312 under normal conditions, and the quantitative extrusion cylinder 31 is positively pressed The mechanism 32 and the reverse pressing mechanism 33 form a quantitative forming cavity 314 for filling and compressing the crushed kitchen waste into small pieces. The reverse pressing mechanism 33 compresses the kitchen waste into small pieces. Finally, the top pressure is released to open the molded garbage outlet 312, so that the kitchen waste compressed into small pieces is pushed out of the quantitative molding cavity 314 by the forward pressure mechanism 32 and falls into the garbage collection bucket 4. The feeding port 311 is located at the quantitative molding The top of the chamber 314 is in communication with the pulverizing pool 21, and the drainage hole 31...

Embodiment 3

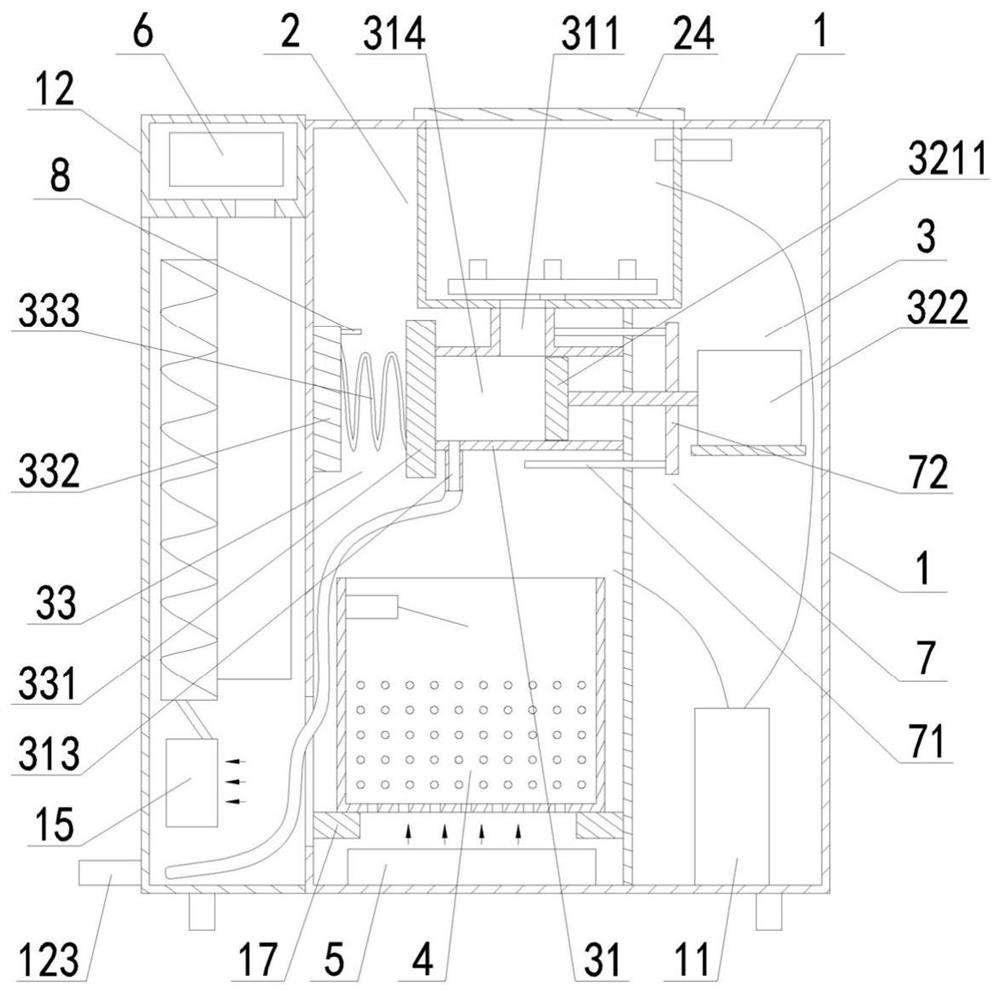

[0064] Such as image 3As shown, the extrusion molding mechanism includes a forward pressure mechanism 32 and a reverse pressure mechanism 33, wherein the reverse pressure mechanism 33 seals the molded waste outlet 312 under normal conditions, and the quantitative extrusion cylinder 31 is positively pressed The mechanism 32 and the reverse pressing mechanism 33 form a quantitative forming cavity 314 for filling and compressing the crushed kitchen waste into small pieces. The reverse pressing mechanism 33 compresses the kitchen waste into small pieces. Finally, the top pressure is released to open the molded garbage outlet 312, so that the kitchen waste compressed into small pieces is pushed out of the quantitative molding cavity 314 by the forward pressure mechanism 32 and falls into the garbage collection bucket 4. The feeding port 311 is located at the quantitative molding The top of the chamber 314 is in communication with the pulverizing pool 21, and the drainage hole 313 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com