Mosquito-repelling volatile core and preparation method thereof

A mosquito repellent and selection technology, applied in the field of mosquito repellent dispersing core and its preparation, can solve the problems of difficulty in applying mosquito repellent effective substances, unsatisfactory coating effect, difficult control of adjustment effect, etc., and achieves simple preparation method and low cost Process cost, the effect of slowing down the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

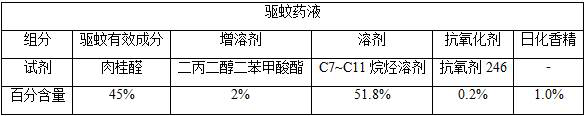

Embodiment 1

[0027] The components and proportions of the reagents listed in Table 1 are prepared to obtain the mosquito repellent liquid, and then mixed with polyalkyl silicone resin at a weight ratio of 100:100 to obtain a combined dripping solution. Add 150 mg dropwise on the non-woven fabric to prepare Mosquito repellent dispersing core Example 1.

[0028] Table 1

[0029]

Embodiment 2

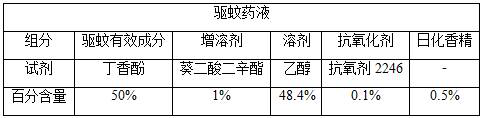

[0031] The components and proportions of the reagents listed in the following table 2 are prepared to obtain the mosquito repellent liquid, and then mixed with liquid butadiene rubber in a weight ratio of 100:120 to obtain a combined dripping liquid, and the combined dripping liquid is Add 240 mg on the UPE sintered sheet to prepare the mosquito repellent dispersing core Example 2.

[0032] Table 2

[0033]

Embodiment 3

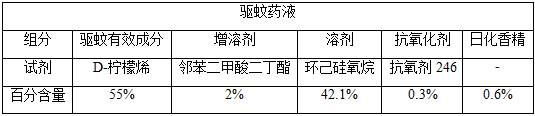

[0035] The components and proportions of the reagents listed in Table 3 are prepared to obtain the mosquito repellent liquid, and then mixed with polyisoprene at a weight ratio of 100:180 to obtain a combined dripping liquid, and the combined dripping liquid is Add 350mg to the lignin modified foam material to prepare the Mosquito repellent dispersing core Example 3.

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com