Super-tensile gel electrolyte ink suitable for aerosol printing and preparation method thereof

A gel electrolyte and aerosol technology, which is applied in the direction of electrolyte immobilization/gelation, fuel cell half-cells and primary battery half-cells, etc., to achieve fast cross-linking speed, delay gelation, gelation Thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

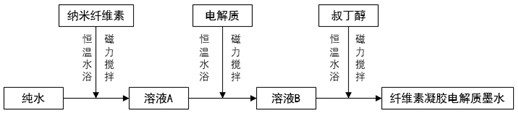

[0050] A kind of super-stretch gel electrolyte ink suitable for aerosol printing and its preparation method such as figure 1 As shown, the specific steps are as follows:

[0051] The electrolyte used in neutral gel electrolyte ink is sodium chloride, and the solvent is pure water; the crosslinking agent and reinforcing agent are nanocellulose; the cellulose dispersant is tert-butanol

[0052] Step 1: Mix pure water as a solvent and nanocellulose as a crosslinking agent at a mass ratio of 10:0.4, and stir in a constant temperature water bath at 60°C for 2 hours by magnetic stirring at a speed of 430 rpm to obtain a clear and transparent solution A;

[0053] Step 2: Mix the prepared solution A with the electrolyte at a mass ratio of 4:0.8, and stir in a constant temperature water bath at 60°C for 3 hours at a speed of 450 rpm to obtain a clear and transparent solution B;

[0054]Step 3: Mix the solution B with the dispersant tert-butanol at a mass ratio of 10:0.6, and stir at r...

Embodiment 2

[0057] A kind of super-stretch gel electrolyte ink suitable for aerosol printing and the specific steps of its preparation method are as follows:

[0058] The electrolyte used in the alkaline gel electrolyte ink is sodium hydroxide, and the solvent of the ink is pure water; the crosslinking agent and reinforcing agent are cellulose; the dispersant is tert-butanol.

[0059] Step 1: Mix pure water as a solvent and nanocellulose as a crosslinking agent at a mass ratio of 12:0.8, and stir in a constant temperature water bath at 60°C for 3 hours to obtain a clear and transparent solution A;

[0060] Step 2: Mix the solution A with the electrolyte sodium hydroxide at a mass ratio of 11:0.7, and stir at room temperature for 5 hours to obtain a clear and transparent solution B;

[0061] Step 3: Mix the solution B with the dispersant tert-butanol at a mass ratio of 5:1.2, and stir in a constant temperature water bath at 60°C for 4 hours to obtain an alkaline gel electrolyte ink;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com