Deepwater pressure testing system

A pressure test and deep water technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of low working efficiency of the test system and cannot meet the needs of frequent use of the test system, and achieve simplification Installation method and installation structure, convenient maintenance and operation, and guaranteed hoisting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the purpose, structure and function of the present invention, a deep water pressure testing system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

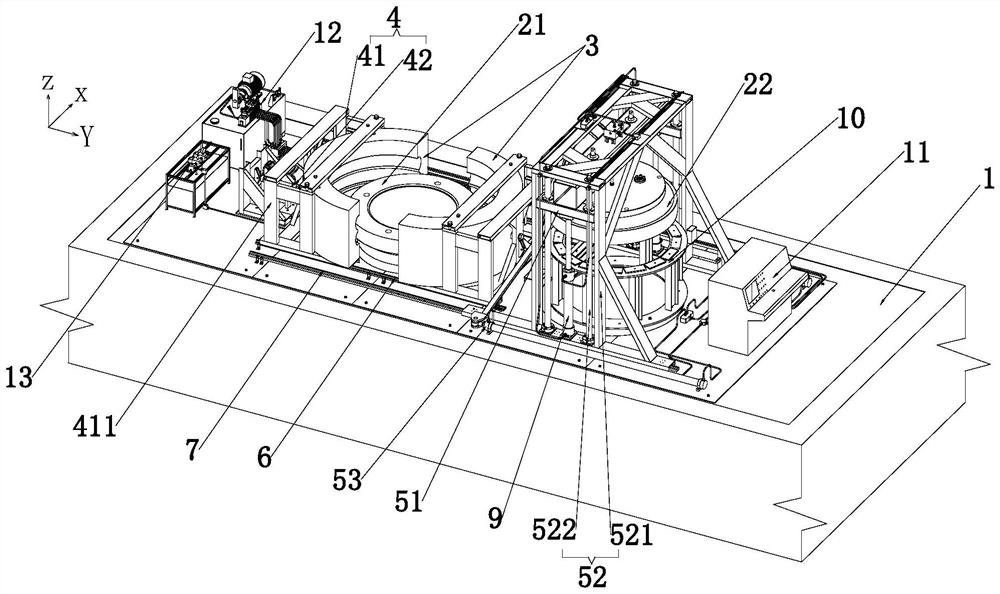

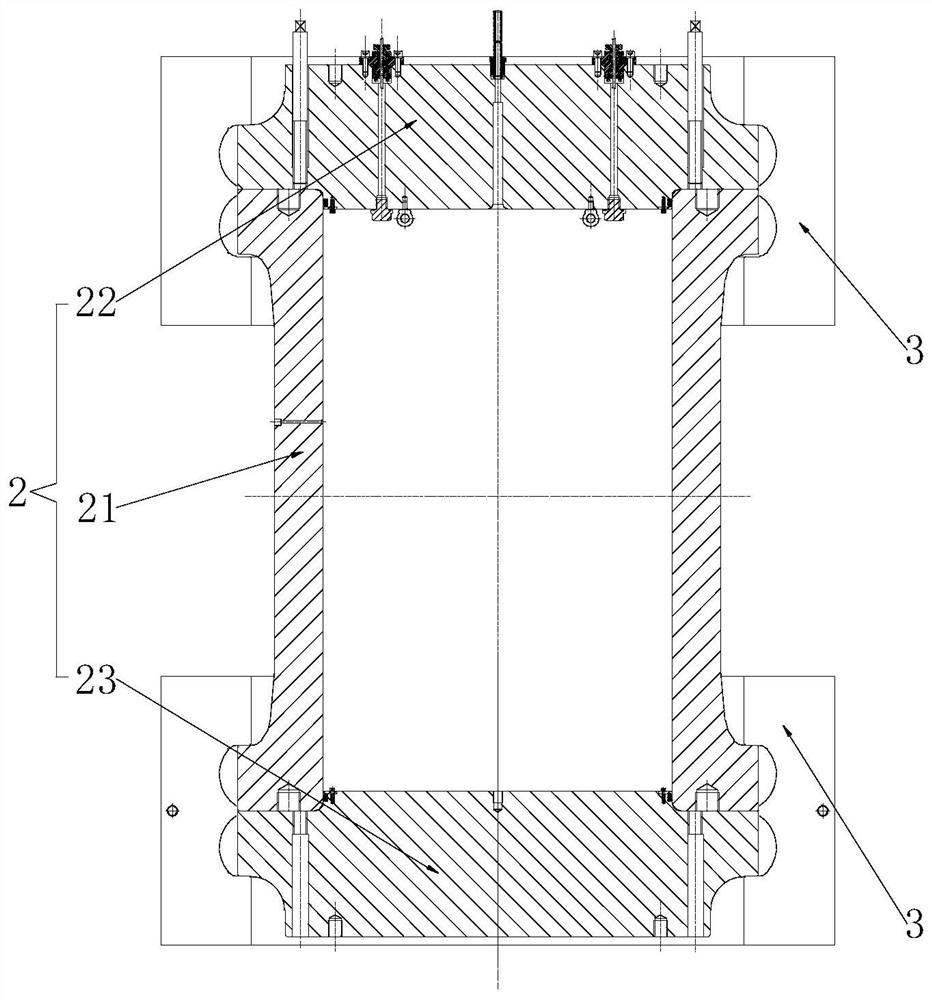

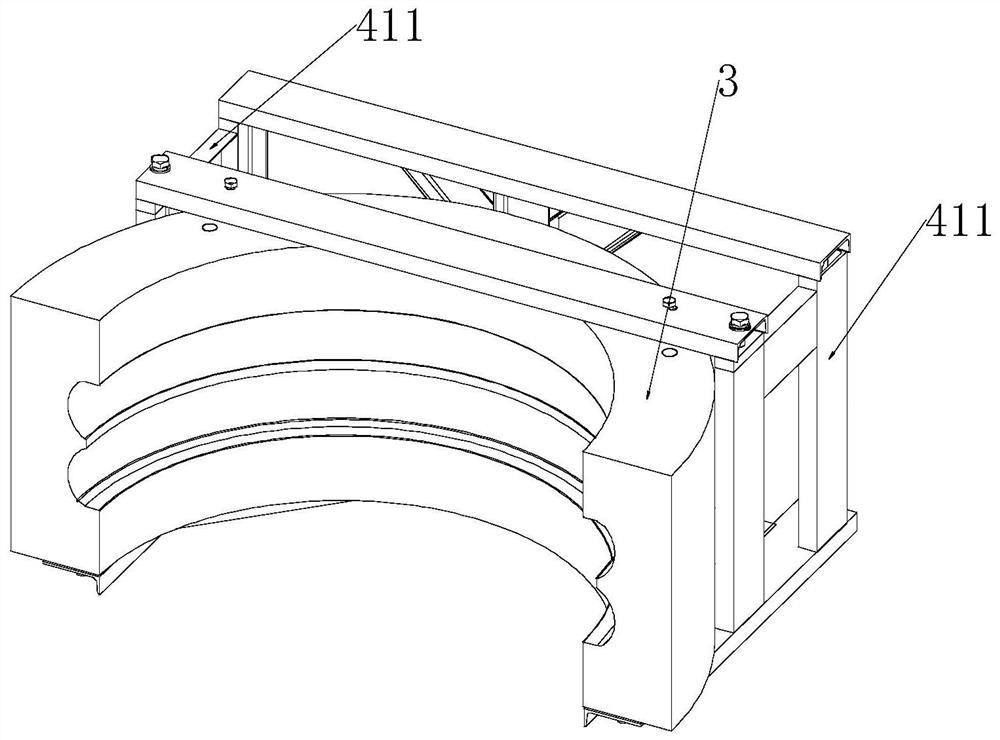

[0032] Such as figure 1 , figure 2 , Figure 6 As shown, the main structure of this embodiment includes a pressure-resistant cabin 2 , a clamp opening and closing assembly 4 , a top cover lifting and translation assembly 5 , a top cover placement frame 10 , an electric control system 11 , a hydraulic system 12 and a high-pressure water pump 13 . The clamp opening and closing assembly 4 includes two connecting frames 41 respectively connected with semicircular clamps. The connecting frames 41 are movably arranged on the foundation 1 , and the two connecting frames 41 can open or close the clamp 3 . Multiple joints of the clamp 3 and the connecting frame 41 are subjected to force, which can avoid stress concentration. The top cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com