Glass roof automatic gluing intelligent trolley

A technology for glass roofs and smart cars, which is applied to roofing, tools for roofing engineering, construction, etc., can solve the problem that excess colloid cannot be scraped off, and achieve the effect of avoiding excess colloid and quickly replenishing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

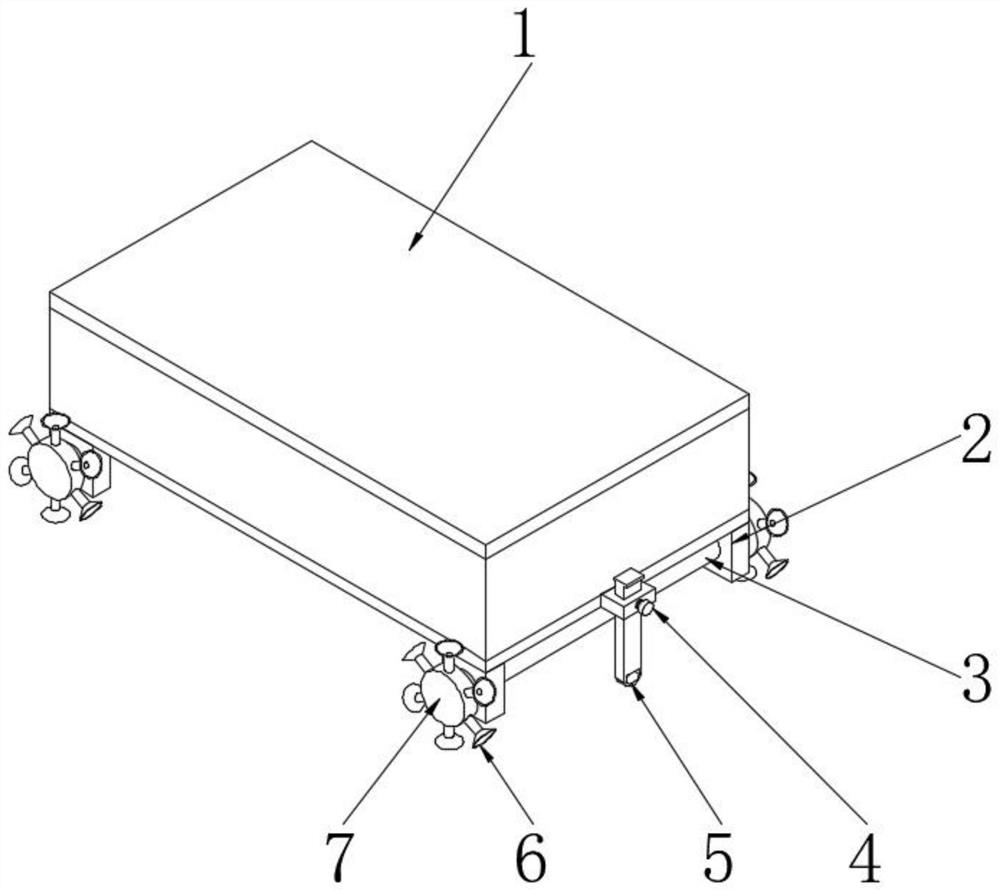

[0023] See Figure 1-4 An automatic gluing Glass Roof Smart car, comprising a main body 1, the bottom corners of the main body 1 are fixedly mounted bump 2, 2 twenty-two four bumps as a set, between the two projections of each set of 2 is provided with a moving assembly, a plastic component is provided for detecting the body 1, the side of the body 1 is fixedly mounted squeegee assembly.

[0024] In a particular embodiment of the present invention, by providing the moving assembly, the car can be easily moved in the glass house surface, squeegee for scraping the excess component may be a colloid, to avoid a large number of gluing the remaining colloidal, by providing the detecting gluing assembly, aging can be detected in the colloid, and the leaking of the fast fill plastic.

Embodiment 2

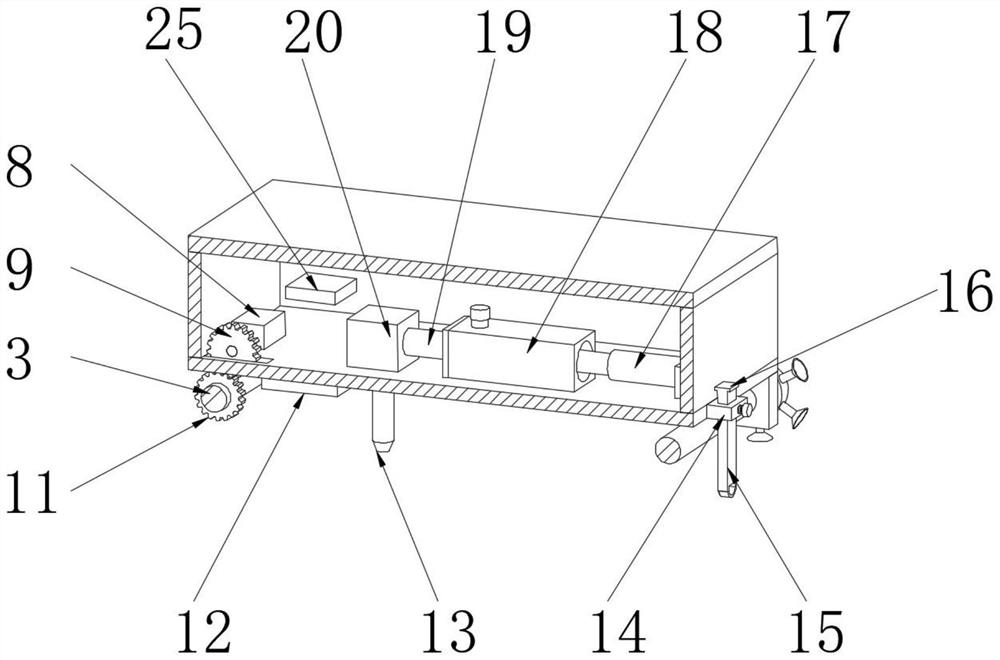

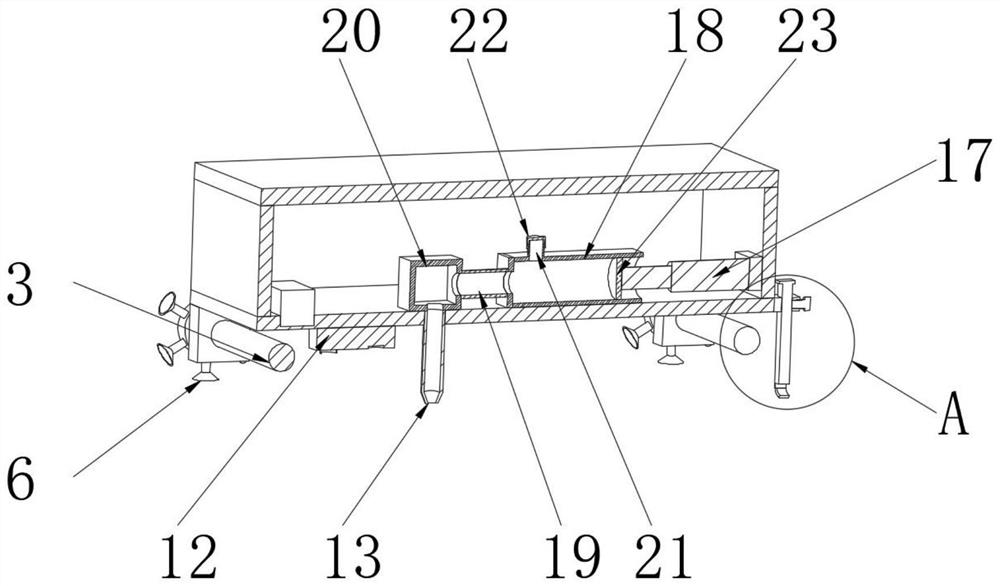

[0026] This embodiment is a modification made in Example 1 above, see the specific figure 2 and image 3 Detecting gluing assembly comprising a distance sensor 12, a distance sensor 12 is fixedly attached to the lower surface of the main body 1, inside the main body 1 is fixedly mounted a square casing 20, inside the main body 1 and the square shell side 20 is fixedly mounted hose 18, square between the hose 18 and the housing 20 is attached to the connecting tube 19 fixed to the lower surface of the square case 20 is fixedly attached adhesive tube 13, coating tube 13 extends to the outside, the inside of the main body 1 and a side hose 18 at the position corresponding to electric push rod 17 is fixedly mounted, one end of an electric push rod 17 extends to the top of the hose 18 and the pushing piece 23 is fixedly connected.

[0027] The present embodiment: if the laser is reflected by the receiver by means of laser projection distance sensor 12 emitted in the aging colloidal desc...

Embodiment 3

[0029] This embodiment is a modification made in Example 2 above embodiment, see specifically figure 2 and image 3 , Is fixed inside the main body 1 is attached to the controller 25, the controller 12 is electrically connected to a distance sensor 25 and the controller 25 and the motor 17 is electrically connected to the push rod.

[0030] The present embodiment: when detecting a leakage point distance sensor 12, the electrical signal may be transmitted to the controller 25, the controller 25 by transmitting electrical signals to the electric push rod 17, the rod 17 by an electrical signal controlling the electric elongated, pushing plate 23 so that the inside of the hose 18 on colloidal extrusion, so as to achieve fill gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com