Bacillus subtilis, phaffia rhodozyma and rhizopus mixed tobacco fermentation method

A technology of Bacillus subtilis and Phaffia rhodozyma, applied in the field of microorganisms, can solve the problems of insufficient aroma quantity, high irritation, monotonous aroma quality and the like, and achieve the effects of improving aroma quality and aroma quantity, improving quality and improving sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

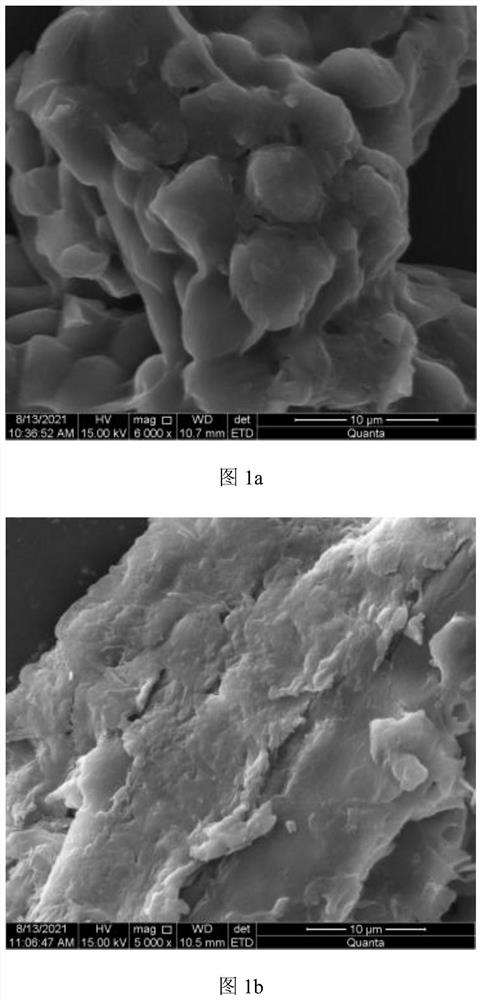

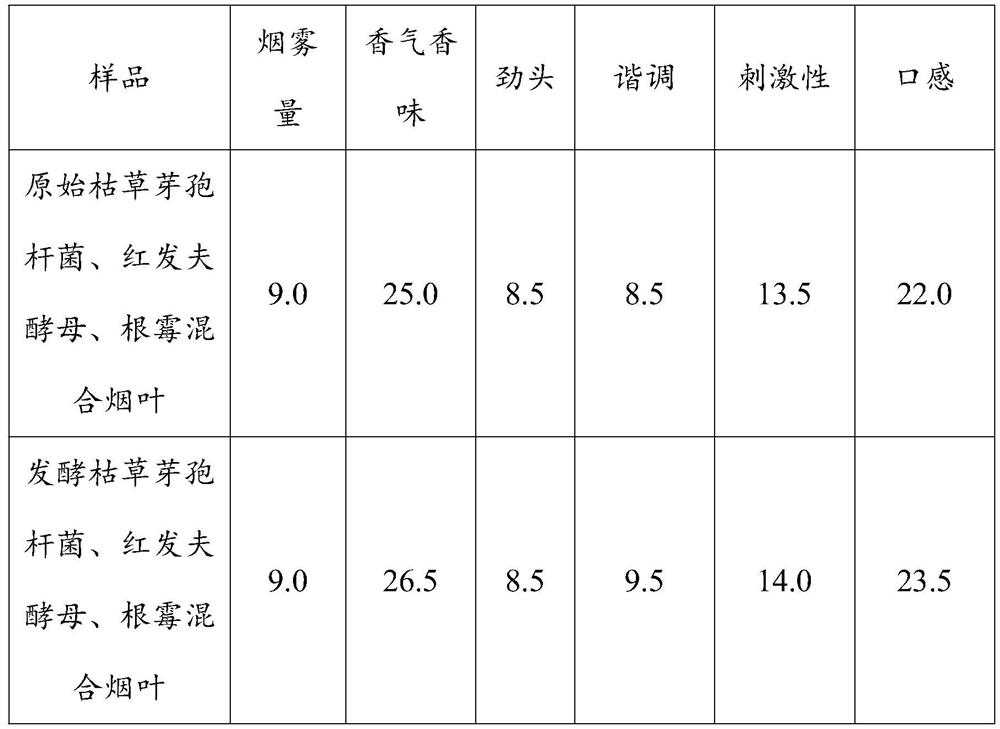

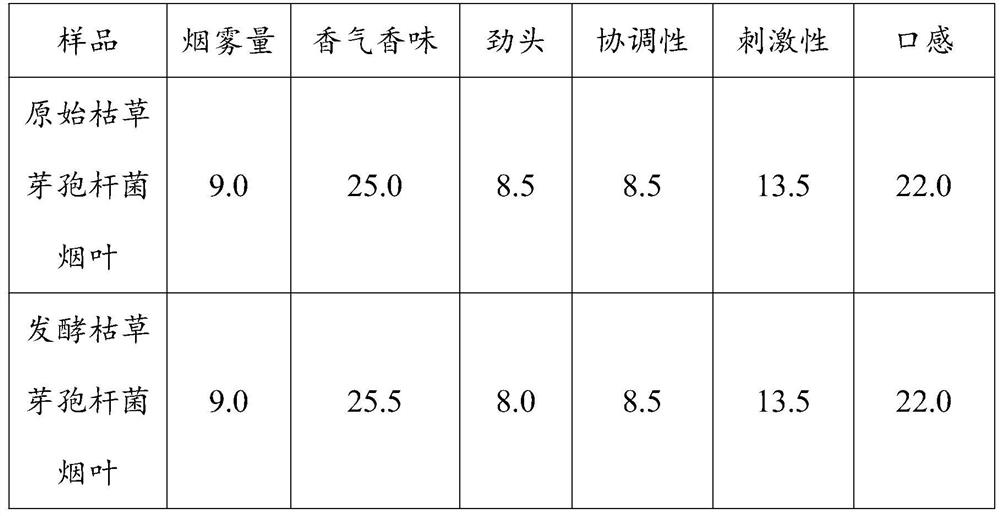

[0020] Example 1 Bacillus subtilis, rhizopus and Phaffia rhodozyme mixed fermentation tobacco leaves

[0021] (1) Strain activation: Bacillus subtilis (DES-59) and Phaffia rhodozyme (Y119) were inoculated on LB agar medium and YPD agar medium respectively for activation by streaking on the plate, cultured at 37°C for 24 hours, Culture at 22°C for 5-7 days;

[0022] (2) Preparation of seed liquid: Inoculate the single colonies of Bacillus subtilis and Phaffia rhodozyme in the plate of step (1) into LB liquid medium and YPD liquid medium, and cultivate them at 37°C for 20h and 22°C for 28- 29h, OD 600 1.6-1.8, 1.8-2.0 respectively;

[0023] (3) Preparation of mixed bacterial liquid: mixing equal volumes of Bacillus subtilis seed liquid and Phaffia rhodozyme seed liquid to obtain mixed bacterial liquid;

[0024] (4) centrifugation: centrifuge the mixed bacterial liquid of step (3) at a rotating speed of 10000rpm for 5-10min, and collect the bacterial cells;

[0025] (5) Washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com