Method for predicting degradation rate of organic pollutants in actual water ultraviolet advanced oxidation process

A technology of advanced oxidation and degradation rate, applied in the direction of testing organic pollutants, water pollutants, chemical instruments and methods in water, etc., can solve the problems of large workload, long time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

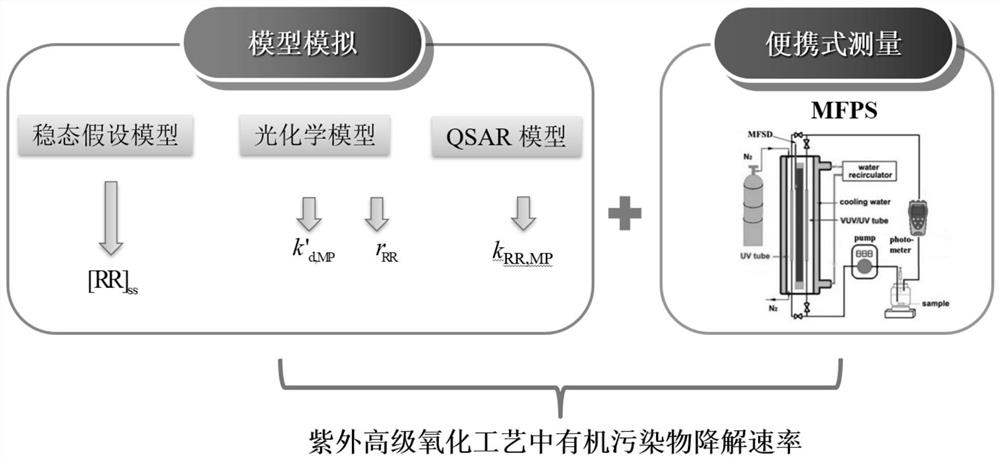

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

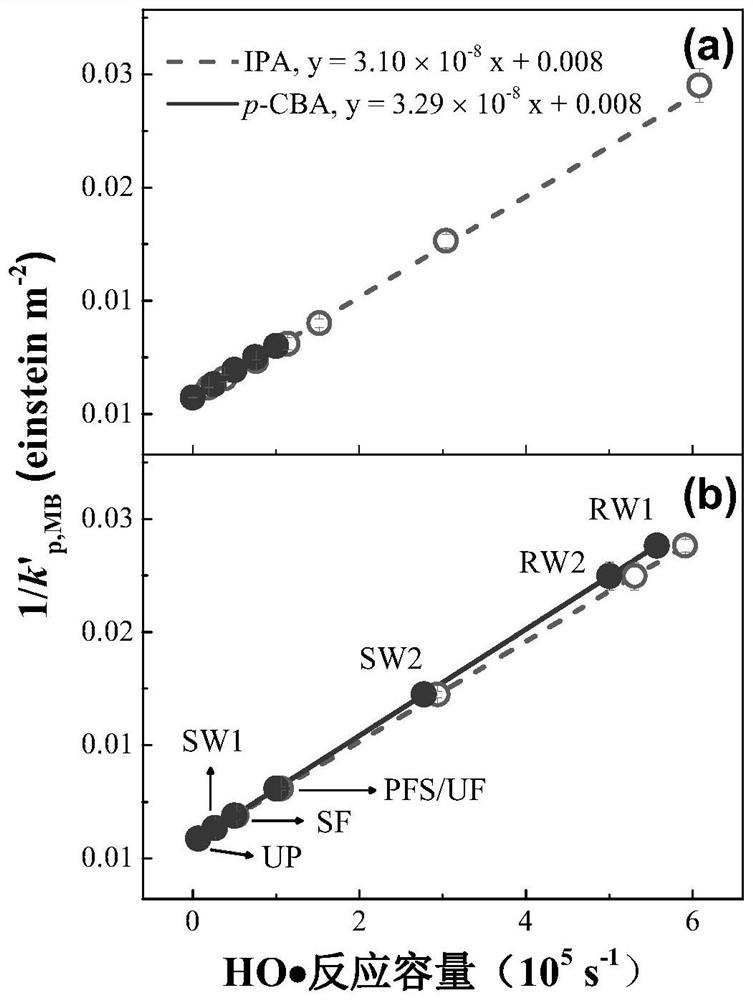

[0160] Embodiment 1, measure the free radical reaction capacity of different actual water bodies and actual water body UV / H 2 o 2 Prediction and Experimental Verification of Degradation Rate of Organic Pollutants in Process Treatment

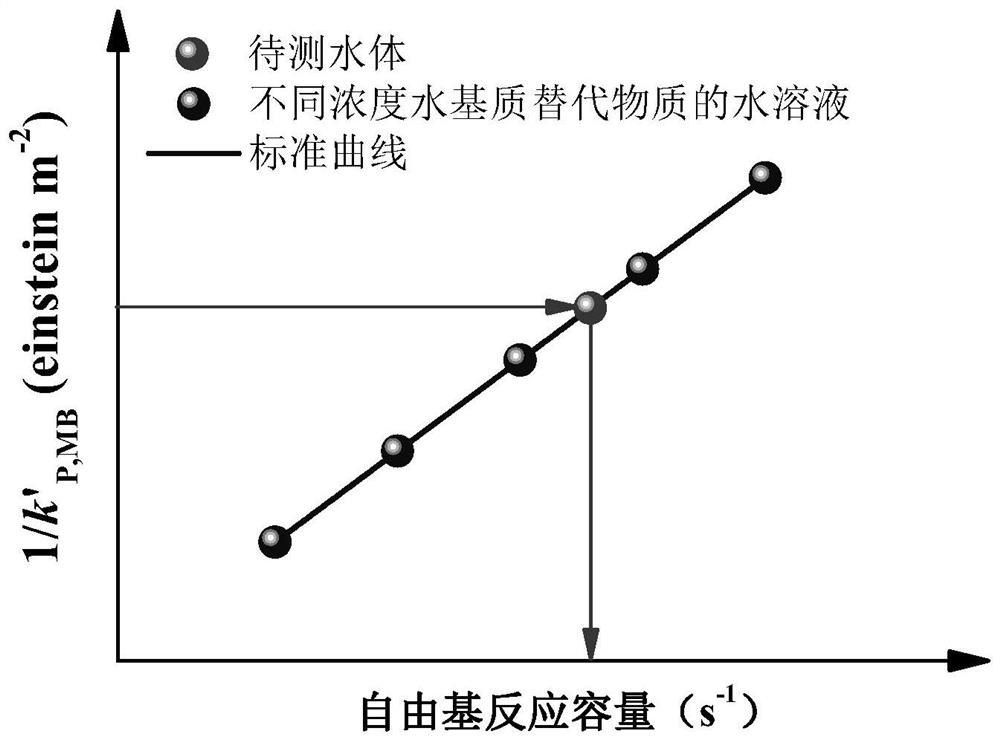

[0161] (1) Use the water matrix substitute substance IPA or p-CBA to simulate the composition of the background water body, and add the probe MB to [IPA] 0 = 0, 10, 20, 40, 60, 80, 160, 320 μM or [p-CBA] 0 = 0, 5.0, 10, 15, 20 μM in aqueous solutions of different concentrations of water-based surrogate substances, probe [MB] 0 = 5 mg L -1 , to obtain the initial system of the simulated water body; using UV / H 2 o 2 (MFPS as photoreactor, [H 2 o 2 ] 0 = 25 mg L -1 , the UV light intensity is 3.98×10 -4 einstein m -2 the s -1 , the water circulation temperature is 25°C) process to degrade the initial system of simulated water body, measure the concentration of MB in different concentrations of water matrix substitute substance solution ...

Embodiment 2

[0173] Embodiment 2, actual water body UV / Cl 2 Organic pollutant degradation rate prediction and experimental verification are tested according to the method in Example 1 in the process treatment, and the test conditions and results are as follows:

[0174] (1) Use the water matrix substitute substance BA to simulate the composition of the background water body, and add the probe MB to [BA] 0 = 0, 10, 20, 40, 60, 80μM of different concentrations of water-based substitute substances in aqueous solution, add 0.5mM nitrobenzene to mask HO · , probe [MB] 0 =5 μmol L -1 , to obtain the initial system of the simulated water body; using UV / Cl 2 (MFPS as photoreactor, [Cl 2 ] 0 = 5 mg L -1 , the UV light intensity is 3.98×10 -4 einstein m -2 the s -1 , the water circulation temperature is 25°C) process to degrade the initial system of simulated water body, measure the concentration of MB in different concentrations of water matrix substitute substance solution during the degr...

Embodiment 3

[0185] Embodiment 3, actual water body UV / S 2 o 8 2- Prediction and Experimental Verification of Degradation Rate of Organic Pollutants in Process Treatment

[0186] Test according to the method in embodiment 1, test condition and result are as follows:

[0187] (1) Use the water matrix substitute substance BA to simulate the composition of the background water body, and add the probe MB to [BA] 0 = 0, 5, 10, 20, 30, 40 μ M in the aqueous solution of different concentrations of water-based substitute substances, add 0.5 mM nitrobenzene to mask HO · , probe [MB] 0 =5 μmol L -1 , to obtain the initial system of the simulated water body; using UV / S 2 o 8 2- (MFPS as photoreactor, [S 2 o 8 2- ] 0 =200mg L -1 , the UV light intensity is 3.98×10 -4 einstein m -2 the s -1 , the water circulation temperature is 25°C) process to degrade the initial system of simulated water body, and measure the concentration of MB in different concentrations of water matrix substitute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com